How bespoke sticker production can boost revenue

We spoke to Antigro Designer about its new client-tailored software that aims to reinvent sticker production.

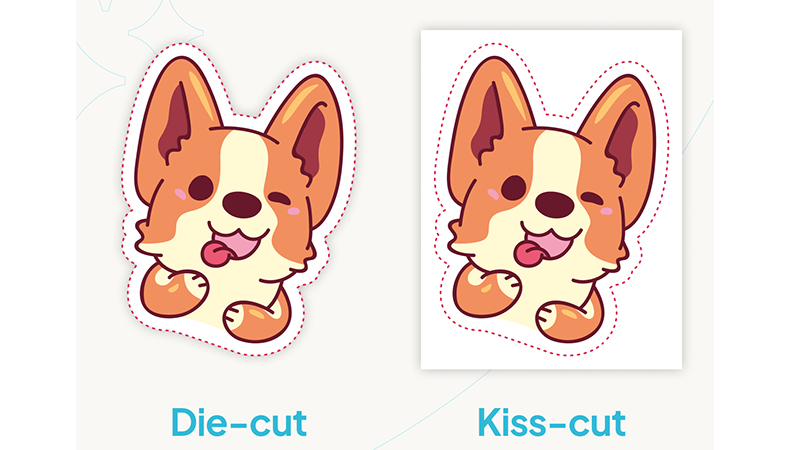

Demand for personalised and professional-level quality stickers is growing, both for businesses (B2B promotional stickers) and for social media influencers and e-commerce businesses (B2C brand awareness and customer engagement). The size of the global die-cut sticker market is massive: it was valued at US$53.2bn in 2023 and is anticipated to reach US$69.2bn by 2028. So how can printers create and distribute highly personalised, high-value die-cut stickers?

In sticker production in the past, printers have been deterred by laborious and time-consuming exchanges between customer and printer to generate batches of stickers. They require a more intuitive, streamlined and powerful product, configured to the firm’s own specific size and needs.

Wacław Mostowski, CRO and co-founder of Antigro Designer, conducted solid research into producing stickers, an area then untouched by the firm. He discovered that the majority of printers were still asking customers to upload files, using a graphic designer to create the proof and then sending back to the client for approval. Other printers, who possessed the correct print and cut machines for sticker production, were discouraged by the constant approval and adjustments from the client, found it unprofitable, and stopped production.

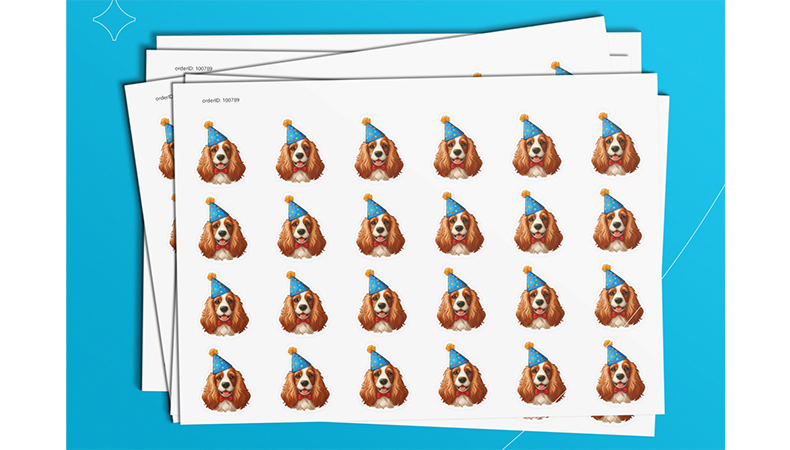

To solve these problems and remove the manual sticking points, Antigro Designer constructed Sticker Builder, a new white label solution for e-commerce businesses and print houses to increase margins on highly personalised die-cut stickers and get them to market fast. It is integrated with the client’s storefront, allowing high-value customisation at the point of purchase, and creates print-ready files for multiple substrates. It is also scalable for the customer – whether they want to sell a few hundred stickers a month or millions.

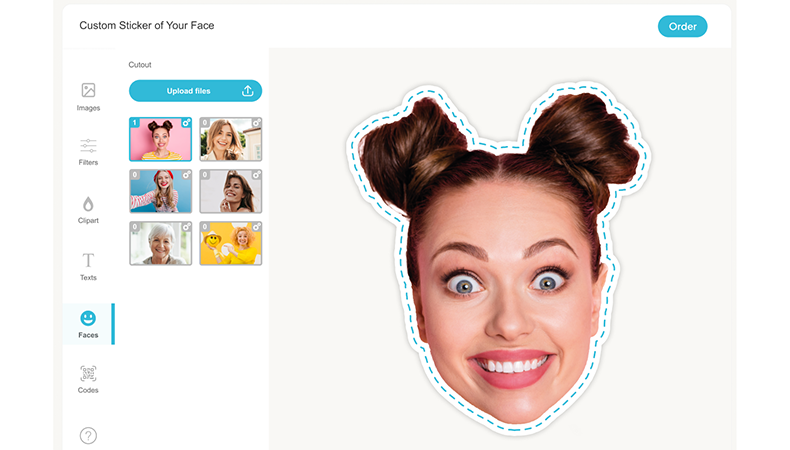

The end customer simply uploads their image to Sticker Builder and then sets the parameters: quantity, size (preset or custom) and material (e.g. Orajet, Siser). The price of the order changes in front of the customer’s eyes as the quantity and size are adjusted.

A cutline is automatically generated – either tight, medium or loose – depending on the customer’s needs: imposition requirements, for example. The background colour can be adjusted, and the customer can also add a variety of filters (saturation, hue etc) to the artwork. For example, if the printer can offer holographic or prismatic effects, this can be accommodated.

Sticker Builder also supports most file formats: the most important and those most likely to be uploaded by an end user are PNG and JPEG files (white backgrounds can be automatically removed from JPEGs). It can also manage SVGs and PDFs, which are increasingly popular, and they are also planning to include Adobe Illustrator and EPS files in the future. “Therefore, we cover 99.9% of customer needs,” says Wacław.

Stickers for social media

Sticker Builder also satisfies the needs of social media influencers and small businesses, who can for example, add their Instagram handle to a predefined template: Sticker Builder will automatically add the correct social media icon and impose an outline around the text. Or information such as URLs, QR codes can be dropped into predefined templates that can then be further modified

Once the order is confirmed on the website, Sticker Builder automatically generates a ready to print file, with cutlines that avoid acute angles for easier cutting. The number of cutlines is generated (one, for example, or both kiss cut and die cut) and generates the optimum imposition pattern. Therefore, Sticker Builder streamlines the journey to purchase for the end customer as well as for those involved in the production process.

Sticker Builder was showcased at Personalisation Experience in Amsterdam in March 2024. At the event, Antigro partnered with Roland to unveil the process in real time. Visitors were able to scan a QR code, upload a photo, set their preferences and pick up their stickers almost instantaneously at the Antigro booth.

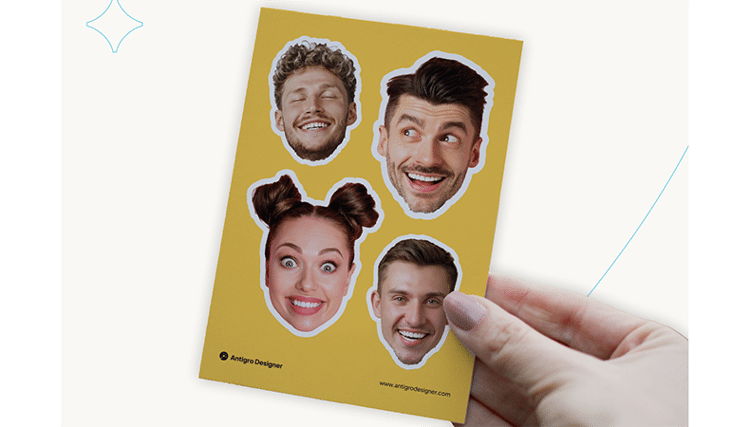

Artificial intelligence (AI) is of course being leveraged to streamline the process further. For example, AI is used for face detection to cut out the face from a photograph and add a background and cutline. This feature has also been made available to entire characters and objects, such as vehicles, for those who want stickers of their car. The power of generative AI is also being employed – for example, a customer can use a text prompt to create a unique image that will be completely individual and not seen anywhere else, particularly important for social media users building brands and personalised touches.

Wacław (right) at Personalisation Experience 2024

Wacław (right) at Personalisation Experience 2024

But how easy is it to integrate the technology into a business? “If it's Shopify or WooCommerce, we will integrate it for our clients,” says Wacław. “The process will take up to two weeks, depending on the workload. If it is, for example, a custom-built system, we have our API documentation available and can assist our clients’ developers with the integration process, but the coding needs to be completed on their end. Our pricing is determined on a job-by-job basis, but we are compatible with any system compatible with REST API.”

The software, says Marcin Madja, CEO and co-founder, will help e-commerce businesses and print houses “double their revenue” by using Antigro’s builders to create highly personalised, high-value customised products and automatically prepare print ready files, avoiding the cost of doing it themselves in-house.

Handling sticker production this way, he says means the cost of the product floats free of the cost of production... a sign of the high added value of personalisation in action.

Become a FESPA member to continue reading

To read more and access exclusive content on the Club FESPA portal, please contact your Local Association. If you are not a current member, please enquire here. If there is no FESPA Association in your country, you can join FESPA Direct. Once you become a FESPA member, you can gain access to the Club FESPA Portal.

Recent news

Sustainability, seaweed and storytelling

Joanne O’Rourke, winner of the Epson Design Award, discusses the interface between storytelling, nature, craft and innovation in her business, and how the Personalisation Experience 2025 was a career-defining moment.

What’s new in stamping foils? Bringing extra sparkle to print products

Stamping foil can help your products to really stand out – and you can probably do it with the equipment you already have. We speak to Matt Hornby of foil specialists Foilco.

The intelligence behind the ink: how AI is changing printing forever

Keypoint Intelligence, the global market data leader for the digital imaging industry, showed the growing application of artificial intelligence to all facets of printing at the SmartHub Conference at the Personalisation Experience 2025, co-located at the FESPA Global Print Expo earlier this month.