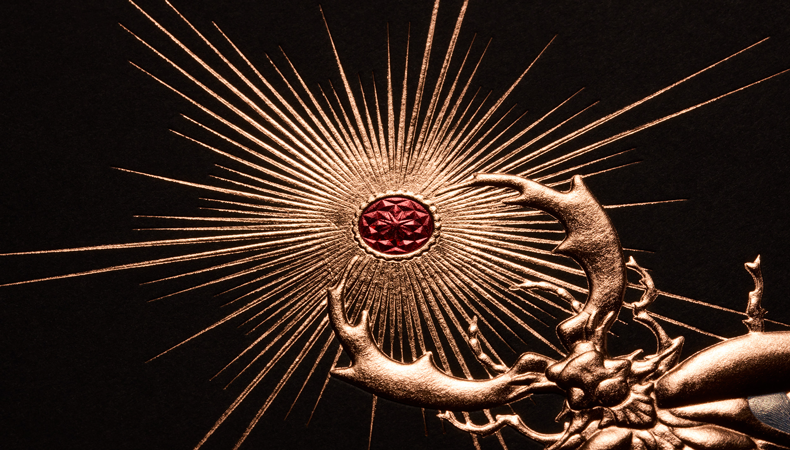

What’s new in stamping foils? Bringing extra sparkle to print products

Stamping foil can help your products to really stand out – and you can probably do it with the equipment you already have. We speak to Matt Hornby of foil specialists Foilco.

Adding metal foil to indicate the importance or luxury of something has been a concept for hundreds of years. Even back as far as the eighth century, one gospel book is known as the ‘Codex Aureus’ – aurum being Latin for gold – because of its metallic decoration. More than a millennium later, as any glance around a typical retail environment will prove, it’s an idea that still remains popular.

“Stamping foil is attractive and grabs the attention of potential customers. If you walk through a duty-free area, have a look around and you will see that nearly every one of those products will have a stamping foil on it, whether that’s cigarettes, perfume, cosmetics or alcohol,” Matt Hornby, Chief Creative Officer of British foil-stamping innovators Foilco says.

“And it’s not just on those premium products. You’ll find foil stamping used to apply metallic or holographic effects on your wheelie bins that features the council’s name. Or on the tipping of the numbers on your credit card. Or on birthday cards. Once you see it, you can’t unsee it!”

Getting started

With such a long history, the processes used in foil stamping have understandably developed in a variety of ways. There is traditional hot foiling, cold foiling and – in more recent years – digital foiling.

“Hot stamping foil already has the glue dried on the back of it – it is a complete process in one. All you need is a brass stamping die to stamp onto it,” Matt says.

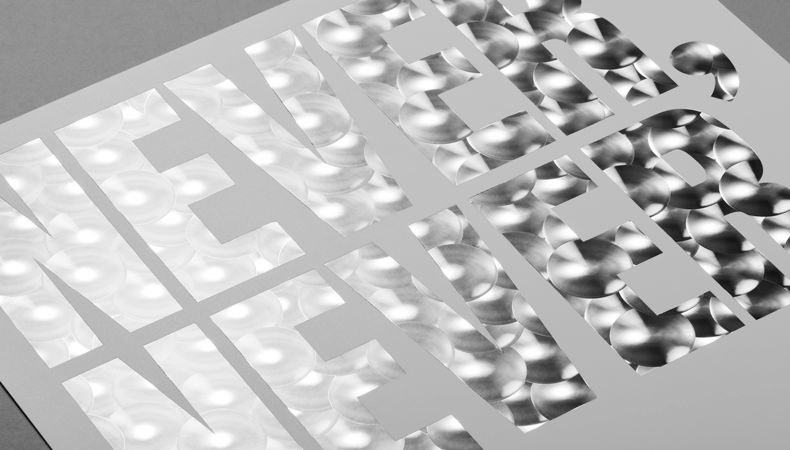

“But digital foiling is more relevant to FESPA members as it involves first putting down inks or varnishes – you simply print the graphic as you would print anything else – and then you place the stamping foil down over the top of toner, print receptive varnish or primer, or even over a digital screen for textiles.

Matt Hornby, Foilco

Matt Hornby, Foilco

“This is pushed together through the rollers of a heated laminator. We put the material through with the foil on the top and that heated laminator will bond the foil with the ink/ varnish. Once the adhesive you have printed gets warm and tacky, the foil will transfer onto the surface of the adhesive and bond together. Some applications require post curing for them to become a more stable product.”

The good news is that getting started with foiling doesn’t require a large initial outlay.

“The machines some FESPA members have will most likely already be able to put down the primer adhesive or the primer varnish on the application,” Matt says.

“Conversations with your ink supplier and your machine supplier need to be started to determine just what level of quality you can achieve. We like to encourage more companies to start the experimental process.

“You don’t even have to use specific foils when experimenting. You could take a textile-grade foil – a foil that goes onto a t-shirt to make a brand name or logo look shiny – and use it with a toner press. The foil will still stick onto the toner even if it is not quite the perfect grade.”

Bright future in personalisation

The growing trend for personalisation has made the adoption of digital foiling – to make low or single-run products feel truly special – even more attractive.

“There’s a very lucrative market for digital foiling at the moment because it allows people to create individual foiled garments, stationery or books,” Matt says.

“With conventional hot stamping, you traditionally require a plate of magnesium or brass with artwork etched or CNC-engraved into it. Once that is made, it’s costly and time-consuming to change things from print to print. But you can individualise with toner and digital foiling, which still allows for the decorative process of delivering metallic, holographic and gloss pigment stamping foils.

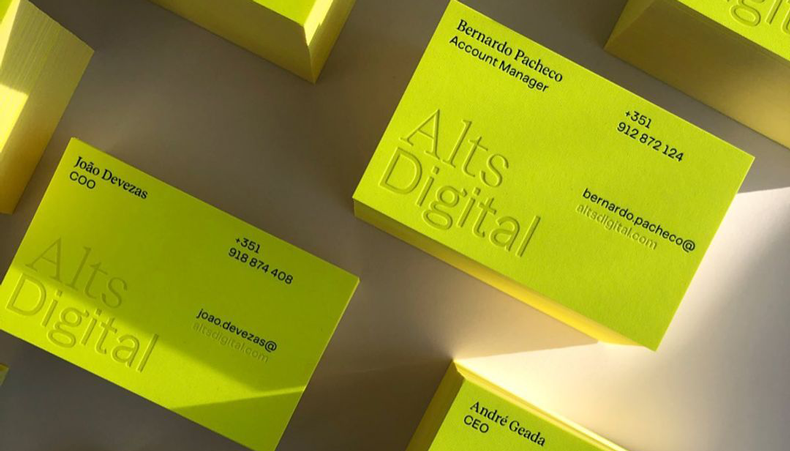

Another area of growth is branding for start-up luxury brands.

“We see that with independent chocolatiers, for example. These start-up companies might start business from home as a very small set-up and they want to secure some retail presence, so they add stamping foil to their packaging to raise the perception of premium and luxury, and to be noticed in heavily populated food aisles and retail environments,” Matt says.

“Think about when you were a child: which was the most valuable trading card or sticker? It was the foil one. We work with those manufacturers today and they still add holographic or gold foiling on their special cards. The interesting thing with trading cards we see now is that companies are using a digital print to create a raised varnish and then adding a foil on the top of that.”

A sustainable alternative

But perhaps the most interesting thing about foiling, especially in the current climate and its focus on sustainability, is that it doesn’t hinder the recycling process of the finished product. The foil coating weights that are transferred are incredibly thin, at around two to three microns.

“We undertook an independent study with SGS-IPS Testing [an independent testing company for paper, packaging and consumer products] to look at paper with varying percentages of stamping foil coverage. We covered 80% of a piece of paper with stamping foil and it did not affect the repulping process,” Matt says.

“We repulped the paper with foil in the same way that paper is broken down to separate the ink from it. When the paper is being recycled, the foil and the inks rise to the surface and this residue is then taken away and is generally used in aggregates.”

So, it seems that foiling offers a significantly better solution for recycling than lamination.

“If somebody laminates to a piece of paper, that laminated board is often no longer recyclable; stamping foil is a far more sustainable process for metallisation as decoration. We have been developing a range of foils that allow for use of larger areas of stamping foil onto packaging and labels as a ready alternative to lamination film,” Matt says.

“The biggest difficulty is what do you do with the foil carrier, which is a 12-micron polyester, once it has been transferred? We have been implementing a zero-foil-to-landfill scheme over the last six years where we recover all the carrier material in the UK and take it back to use as an energy source. With our small and medium customers, who are potentially not creating much scale of waste to create viable collection for recycling companies, we help facilitate that recycling for them to make sure that stamping foil carrier doesn’t end up in landfill.

“We find that many people just aren’t fully aware what is achievable with stamping foils. We are continually making new colours and finishes and trying to spread the word of the incredibly wide options that we offer. Therefore, we are still on a mission to encourage and support customers and creatives to experiment with new colours, to actively use stamping foils to make their products really look premium, unique and special.”

To find out more about Foilco’s products, visit foilco.com

Become a FESPA member to continue reading

To read more and access exclusive content on the Club FESPA portal, please contact your Local Association. If you are not a current member, please enquire here. If there is no FESPA Association in your country, you can join FESPA Direct. Once you become a FESPA member, you can gain access to the Club FESPA Portal.

Recent news

Sustainability, seaweed and storytelling

Joanne O’Rourke, winner of the Epson Design Award, discusses the interface between storytelling, nature, craft and innovation in her business, and how the Personalisation Experience 2025 was a career-defining moment.

The intelligence behind the ink: how AI is changing printing forever

Keypoint Intelligence, the global market data leader for the digital imaging industry, showed the growing application of artificial intelligence to all facets of printing at the SmartHub Conference at the Personalisation Experience 2025, co-located at the FESPA Global Print Expo earlier this month.

Regulation guidance: CS3D

How does the Corporate Sustainability Due Diligence Directive (CS3D) affect printers, and what do they need to do to ensure compliance? Sustainability consultant Rachel England outlines everything you need to know.

How to choose the best courier for safe shipping

As a printer, making sure your work is high-quality is only half the job – delivering to the customer on time and intact is just as important. Reliable courier services are vital for your business reputation, so here’s what to look for in a delivery partner, and why automation may be one way you can boost your business.