How to reduce bottlenecks with software automation

Graeme Richardson-Locke discusses the advantages of workflow automation.

Despite all that is currently going on in the World with the disruption caused by COVID-19, and, you as, business owners or managers are processing the day’s business survival tasks you might find some time to consider the advantages of workflow automation as you emerge on the other side of this crisis.

As Technical Support Manager at FESPA I aim to offer insight into how our Printer members can utilise all the available tools to speed up order processing and reduce the risk of printing work that doesn’t meet the customers quality expectations first time, every-time. This can be daunting when addressing the broad array of printing techniques and production environments.

However, it is clear that the increasing use of machine automation in digital printing through systems such as, robotics in material handling and evolving MIS systems are bringing essential efficiencies. The next phase change for many is connecting software and establishing streamlined workflows.

Identifying the areas to focus on requires clearly tuned and predictable print production. This approach does place some constraints on the product offering when compared to more traditional bespoke business models in print. I know from my own experience as a buyer that the simplification of the process for procurement is so fast and clear with good web 2 print providers that it is only the very creative or specialised work that follows a traditional slower order path.

In order to gain more insight , I contacted Malcolm McKenzie at Colour Engine, a UK based technical consultancy offering automation integration services for Printers from colour management to software and script development.

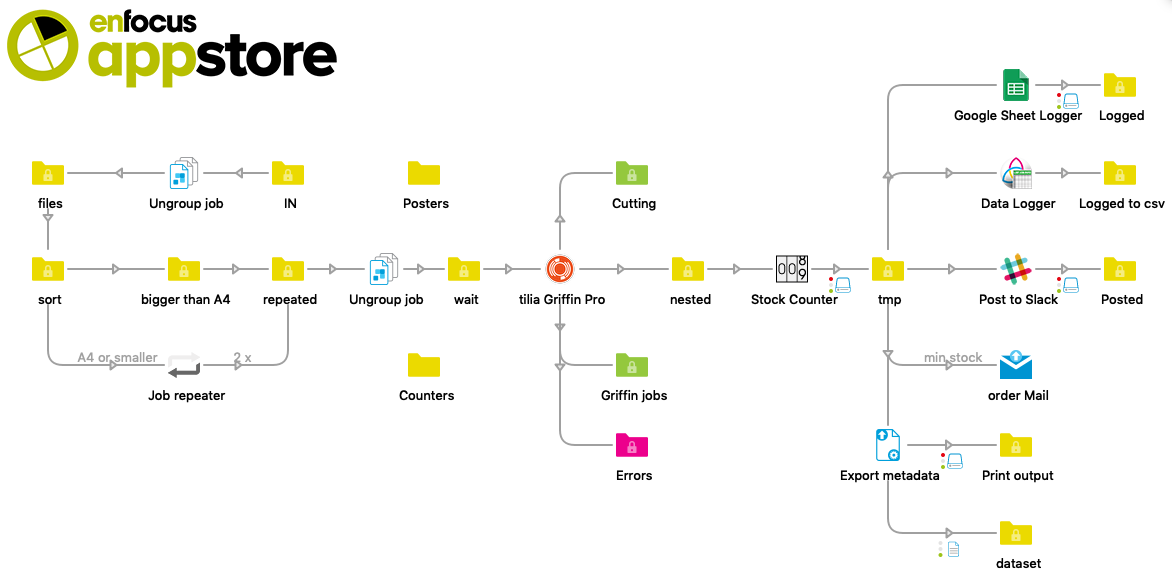

One of the many software products they support is Enfocus Switch, that enables you to build your own custom automated production workflows. By joining different software applications together through custom scripting it becomes possible to, for example, move files from Adobe CC application using it’s JavaScript interface to another application such as Microsoft Outlook through the use of Applescript for Mac OS-X and VBscript for Microsoft Windows.

One example is the opportunity to get inbound customer files landing in a hot folder connected to PitstopPro where a pre-flight check is done to ensure that the artwork meets the needs of the process. This can in-turn trigger an automated email back to the customer to let them know that the file is going through its first check and you will receive a proof shortly. If the file passes that pre-fight examination the next step is to open it up and embed the artwork with an appropriate colour management profile to a PDF proof for approval. If, of course the file fails to meet the requirements then you set up an email detailing what the customer needs to do to resubmit.

Caption: An example of an automated workflow design in Switch.

Caption: An example of an automated workflow design in Switch.

This approach to automation represents an agile alternative to buying into a hosted ecosystem where the opportunity to customise may be more restrictive. Sometimes it’s hard to achieve the optimal workflow unless you can build it specifically around your printed product mix. The choice depends on how deeply you want to get involved and the level of flexibility you need.

Malcolm McKenzie is an Enfocus certified expert and member of the ISO TC-130 (Printing and Graphic Technologies) committee and is very experienced in the technical requirements of workflow automation.

As we began my training day he offered his first piece of sage advice, “start by automating a simple process and grow it from there”’ It may be the case that organising a delivery involves, closing the order, raising and printing delivery notes and parcel labels and sending the invoice or taking payment.

Typically, MIS systems will handle a good portion of these tasks but may not integrate directly into the chosen courier’s booking system. By listing the tasks and sequence of the process this allows you to understand how to connect everything together. You may need, API’s, SQL code XML metadata to be harnessed in pulling the right information to its destination, this is where Enfocus Switch and a bit of expertise comes in . It includes a wide range of ‘widgets’ or API’s that can be interconnected and visual workflow planning that connects the ‘actions’ together to release the printer from tedious repetitive tasks.

After all the aim is to reduce human touch points as much as possible to increase speed and reduce cost, opening capacity to process many more orders.

If you, with the guiding knowledge of someone like Malcolm could map out everything from automated quotes, order acknowledgment, rapid soft proofing, payment and booking-in, you rapidly reach a stage at which the human touch points are greatly reduced and free up staff to work more productively.

Whether you have a Web2print operation or Storefront, Enfocus Switch software print technology has been utilised to significantly improve process efficiencies to the extent that you could handle an exponential increase what is typically becoming a short run, fast turnaround cost competitive market-place.[KY2]

Talking to audiences, businesses, printers, specialists there is a ceiling as to how many staff 'you can throw' at a problem. With inconsistent manual operations, too many cooks can not only spoil the broth but hinder business growth and expansion.

There is now an absolute imperative for printers to identify better ways of working. Immediacy is now ever-present where both direct end-users and print shops need to get proofs out to customers quickly. By fast receipt and control of incoming files, smart businesses are also seeing, fixing and moving on from issues, accelerating, internal decision making and providing a better Service to customers.

The Bluetree Group who market under the Route 1 Print and Instantprint brand could not have achieved such progress without such a high level of software automation. Their 23:17 teamwork mantra is prescient, championing their latest record minimum time to process a job from start to finish (23 minutes, 17 seconds). Service is everything at 25,000 orders per week.

By standardising products, commoditisation for simple (flyers, banners, brochures) or increasingly complex jobs is in vogue, but this can take high levels of expertise to implement, with manual craft skills still required in specialist areas like foil blocking, printing on specialist materials etc.

Summary

Working with Malcolm McKenzie at Colour Engine was a useful and clear training exercise, I could have spent a few with him but at least I got a decent appreciation in a day there.

Whilst Enfocus Switch is not the only automation game in town with other vendors like OneVision, Esko, Print Factory, HP, Efi and Heidelberg all competing with their systems and approaches what is as clear as day is that software automation is required to stay ahead.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The power of digital design tools in screen printing

James Gatica shares how the combination of traditional screen-printing techniques with cutting-edge digital design tools is revolutionising the way designers conceptualise and produce custom decorative pieces.

Key trends and market shifts on Personalisation and Sportswear with Epson

Debbie McKeegan speaks to Duncan Ferguson, VP of Commercial and Industrial Printing at Epson Europe about the market shifts and current trends around personalisation. Duncan shares the key trend of merging both fashion and sportswear.