How reducing waste can lower costs and improve profitability for your business

Nessan Cleary explains how businesses can increase their profit by being more sustainable by reducing energy consumption, improving recycling and most importantly motivating staff to implement these new policies.

These days, where the evidence of climate change is all around us, sustainability has become all the rage pushed upon us by customers and regulations. This need to be environmentally-friendly is often seen as an extra unwanted cost at a time when most businesses are struggling to survive and many economies are skirting around recession. And yet taking a more sustainable approach can help wide format producers to cut costs and improve efficiency, which can only help with the bottom line.

The easiest way to improve sustainability is to eliminate waste wherever possible. For most large format providers, the biggest waste is reprinting jobs to correct errors but better process control can reduce this. That might mean improving your colour management so that additional panels can fit seamlessly with existing ones. Equally, improving automated preflighting to catch problems, and to fix them where possible, can avoid poor files going to print. Or it could simply come down to having better communication with customers to ensure their expectations align with your output.

Small things too can make a difference. Upgrading your imposition software can lead to tighter nesting and better use of media. You could invest in a bulk ink solution, if available, to reduce the cost of buying ink and the time taken to change ink cartridges. Improving the job queue management can help group similar jobs together to reduce time wasted on changing media rolls on your printer.

You can also set up roll-fed printers to print overnight without having to run an extra shift. Depending on how productive your printer is, you may need to invest in a jumbo roll feeder to get the most out of this.

Jumbo roll feeders allow for long uninterrupted print runs. ©Nessan Cleary

Jumbo roll feeders allow for long uninterrupted print runs. ©Nessan Cleary

Taking a proactive approach to maintenance should cut down on machine breakdowns, which can cost you both in terms of the cost of the repairs and the loss of production, as well as any compensation you have to offer to customers for missing deadlines. But anticipating problems makes it far easier to schedule downtime for quieter periods before disaster strikes.

Companies sometimes overlook the benefits of good inventory management, but that inventory represents a chunk of cash that you’ve paid out but have yet to see any benefit from so beware of letting spares and consumables bloom out of control. Most ink will have a limited shelf life so it makes sense to only order that ink shortly before you are likely to need it. The same is also true for cleaning fluids. Equally, many substrates are expensive and shouldn't be left to gather dust in the stores. It’s advisable to keep track of short ends and to list exactly how much is left over on a roll and then use these up wherever possible.

Updating equipment

Sometimes the best route to greater efficiency is to upgrade your equipment. Replacing older UV printers with modern LED models should see a reduction in energy costs, partly because LEDs use less energy but also because they don’t need to be warmed up and kept at their operating temperature. That also saves on the time taken waiting for the machines to warm up and avoids the cost of safely disposing of the mercury vapour lamps.

There is some evidence that resin or latex printers can push up energy consumption because of the heat that is used to activate the curing and dry the water content from these inks. However, the current generation of inks from all the different vendors use considerably less power than earlier iterations. You can take some steps to minimise energy use, by ensuring a constant flow of jobs through the printer so that there's no need to keep it warmed up whilst waiting.

Investing in equipment comes at a cost so a newer printer should also bring something new to the business, such as better image quality or faster speed. There are also hidden costs with printers, such as the degree of maintenance that will be required and the cost of spare parts that need to be factored in. Ideally, a more modern machine should have more automated maintenance procedures, with more remote monitoring to enable preventative maintenance and cut down on service call-outs.

Buildings and people

Your premises will also have a major impact on overall energy consumption, far more so than any piece of equipment. Older buildings, particularly industrial units, often have poor insulation and lighting that will lead to higher energy use.

You may be able to cut down on that energy consumption by thinking outside the box. For example, giving all staff a company fleece could allow you to turn down the heating in the building. Another option is fitting timers or sensors to light switches in areas that are less busy, such as the toilets. You can gain further information through the International Standards Organisation, which has a series of environmental management standards such as ISO 14001 that offer good practical advice on how to save energy. Accreditation to this standard is an effective way of marketing your sustainability credentials.

It’s also worth looking at recycling, especially as some customers are already demanding that printers take back signage has reached its end of life. It’s inevitable that more customers will expect the same, and that this will feature in future regulation. That gives printers the option to charge for disposal. There’s also a chance to recoup some costs through breaking down the prints, reusing some parts and selling on others such as metal or electronics.

Finally, the most important element is motivating your own staff as they will be the ones implementing all these policies. Those businesses that encourage staff to identify problems and to be proactive with machine maintenance will reap the reward of a smoother running operation. Moreover, the staff are the most important asset of any business and should be protected with robust health and safety policies. That will cut down on staff sickness days, reduce the risk of accidents and expensive compensation payouts, and cut down on staff turnover and the additional costs of recruiting and training.

To discover the latest content that covers a wide range of sectors including best sustainable practices sign up for FESPA’s free monthly newsletter FESPA World available in English, Spanish and German.

Recent news

Kodak's 2024 Sustainability Report: A Commitment to a Greener Future

Kodak's 2024 Sustainability Report, "One World, One Kodak," demonstrates a strong commitment to environmental and social responsibility. The report highlights impressive reductions in greenhouse gas emissions (56%) and water withdrawal (31%) and aims for zero waste by 2025. Notably, Kodak is pioneering double materiality assessment in the printing industry, aligning sustainability with financial reporting, and showcasing its products' environmental benefits.

How can printers lower costs on energy usage?

Clare Taylor outlines simple steps for businesses to achieve energy sustainability, focusing on cost savings and staff comfort. It emphasises starting with measuring energy consumption to identify key areas for improvement. Subsequent steps involve managing energy use through behavioral changes and low-cost interventions, like optimizing cooling settings and ensuring equipment is switched off when not needed.

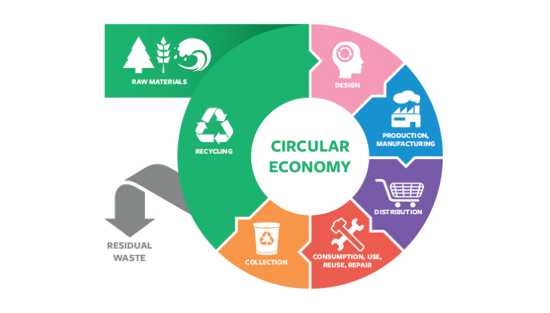

The European Union's circular economy plan

Printing companies must understand the EU's Circular Economy Action Plan (CEAP), part of the European Green Deal. These initiatives drive sustainability, impacting businesses globally, even if not EU-based, through customer requirements. Printers need to be aware of reporting and sustainability expectations to manage risks and retain clients.

A revised look at sustainability in wide format print

Sustainability is crucial for wide-format print, moving beyond marketing to an imperative driven by brands and regulations. Common "eco" claims often mask complexities; true sustainability demands carbon reduction as a core principle. Life Cycle Assessment (LCA) offers data-driven insights for genuine environmental improvement, as demonstrated by UFABRIK's transparent approach.