How can printers lower costs on energy usage?

Clare Taylor outlines simple steps for businesses to achieve energy sustainability, focusing on cost savings and staff comfort. It emphasises starting with measuring energy consumption to identify key areas for improvement. Subsequent steps involve managing energy use through behavioral changes and low-cost interventions, like optimizing cooling settings and ensuring equipment is switched off when not needed.

Simple steps to energy saving

Sustainability in energy use looks beyond reducing climate change impacts and includes financial sustainability in terms of cost savings and/or softening the blow of future energy price rises. Social sustainability, such as staff comfort, also should not be overlooked.

As with many things, a programme to reduce energy starts with measuring.

Measuring

Measuring energy consumption as best you can avoids wasting time and effort on a project that is not addressing your main energy uses: the biggest energy-savings opportunities are not always what you might expect. For a small business with a single meter, measuring can be challenging, but a good-enough estimate can be made to point you in the right direction. For larger businesses with higher and more complex energy use, it may be worth hiring portable energy monitors.

The first thing is to find out how much gas and electricity you use over set time periods so you can see patterns. If you are half hourly metered, that data should be available to you for download and this is ideal, as it allows you to see changes during the day as well as over weekends and seasonal variations. Otherwise, start reading your gas and or electricity meter at least weekly; daily is even better if you can. Regular walks round your site to see what energy using equipment is in use at what times will complete the picture.

The next step to understanding consumption is finding out what your baseline is – that’s the energy used simply to power the building when there is no other equipment in use. Unless you operate 24 hours a day, seven days a week, you can get this by taking two readings at the beginning and end of a non-working period. Doing this in different seasons will tell you if your baseload varies seasonally, for example if you need to use heating for frost prevention in winter.

Once you have your baseline, you can then see the difference building services and operating activities make: heating, cooling, lighting, computers and production equipment. Tracking productivity against energy consumption allows you to use graphs to see how much consumption varies in busier or quieter periods; checking against heating and cooling degree days (which allow you to quantify how hot or cold it has been over a given period) lets you see the influence of heating and cooling. To learn more about degree days, and for free calculations, see https://www.degreedays.net

With half hourly metering you can do this reasonably accurately, without it you can at least see patterns, enough to know whether you’re more likely to benefit from reducing heating demand or cooling demand. Half hourly metering also allows you to check jumps in consumption that don’t match occupancy or production schedules: this can be equipment set on timers that weren’t changed when the clocks changed. Although starting to use energy an hour early isn’t much, over six months it builds up; changing it is an easy save.

Portable data loggers will measure the actual consumption of specific items of equipment, but without them, reasonable estimates are possible based on power consumption, the number of hours in use and, where relevant, the power level used for anything variable.

Managing

Depending on the size of your business and its energy consumption, investments in energy efficiency can take a while to pay back, so a programme of behaviour change, low-cost interventions and of purchasing more energy efficient equipment when it’s replaced may be the most realistic.

For many businesses, cooling offers the best scope for reduction. Tips for this start with looking at the settings, especially if heating and cooling are controlled separately. Recommended settings for office-type environments are that the heating temperature should be set no higher than 19°C and cooling not to come on until the temperature reaches 24°C, leaving a ‘dead band’ of 5 degrees when both are off: it is not unusual to see both on and working against each other.

A change of just one degree in the set point can make a considerable difference to energy consumption, and if there are members of staff who tend to feel too hot or too cold when others are comfortable, it can be useful to look around their workstation. Hot or cold spots can be caused by draughts, solar gain from windows, being directly under an air vent or beside a radiator, which all can be changed with little or no cost.

Internal or external shading reduces overheating from the sun; if using blinds, they work best if lowered before heat builds up, which can mean lowering them before leaving at night to stop heat build-up in the morning before the site opens.

If needed, remind staff how to use the air conditioning efficiently, and specifically to keep windows and doors closed when the air conditioning is on, including internal doors between temperature-controlled production areas and offices.

It is common for energy using items to be left on when not needed, ranging from lights, air conditioning, fans or computers to compressors, which are high users even on standby. Managing these by either staff behaviour or automatic controls is another quick win.

Regular maintenance also offers an opportunity for energy efficiency from clean, well-maintained equipment, especially fans unencumbered by dust.

Investing for savings

These steps are just the beginning, there are many other ways to reduce consumption, but they require investment so are not included here.

Researching these and planning them into your investment programme, checking the availability of energy-efficiency grants and looking for sources of information will help keep you moving forward, whether it’s improving building insulation or upgrading plant.

Topics

Recent news

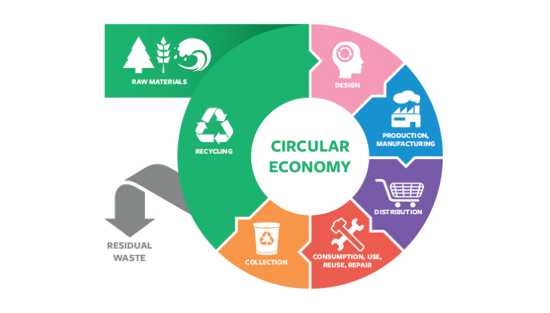

The European Union's circular economy plan

Printing companies must understand the EU's Circular Economy Action Plan (CEAP), part of the European Green Deal. These initiatives drive sustainability, impacting businesses globally, even if not EU-based, through customer requirements. Printers need to be aware of reporting and sustainability expectations to manage risks and retain clients.

A revised look at sustainability in wide format print

Sustainability is crucial for wide-format print, moving beyond marketing to an imperative driven by brands and regulations. Common "eco" claims often mask complexities; true sustainability demands carbon reduction as a core principle. Life Cycle Assessment (LCA) offers data-driven insights for genuine environmental improvement, as demonstrated by UFABRIK's transparent approach.

Empowering the Print Community – Insights from Suzi Ward, MD of FESPA UK

In this podcast episode, Debbie McKeegan interviews Suzi Ward, the Managing Director of Fespa UK, discussing the evolution of the association, its role in supporting the print industry, and the importance of community engagement.

.png?width=550)

The European Union is driving massive sustainability change

The EU's ambitious Green Deal, aiming for climate neutrality by 2050, drives significant sustainability changes. Businesses worldwide, especially printers, must adapt to complex EU legislation. Compliance creates challenges but also new opportunities in areas like packaging and signage.