Why must the print industry recognise software and material innovation

Laurel Brunner argues that the printing industry must recognise the value of both software and material innovation, and be willing to pay for it. Software, though intangible, drives efficiency and reduces carbon footprints. While materials science currently dominates, R&D costs are inherent in all advancements. Paying a premium ensures continued progress, benefiting the industry's evolution and sustainability.

It’s fair to say that people of a certain age in the printing industry can get a bit confused about software. This is not surprising: software is invisible, it’s something you’re told you have to have if your platesetter is to work efficiently. Software’s vital for your digital press and you have to have it to check incoming PDFs, manage workflows and job queues etc. Information technology in general and software in particular is a facilitator. Software provides services the value of which cannot easily be quantified. This may be baffling to many printing company owners, but software efficiencies keep bringing down the carbon footprint of print through efficiency enhancements.

You pays your price and you takes your chances, so they say. Obviously the price you pay should be based on the value that tech provides to your business and what you can afford. But as well as what the product does for the money, the price you pay should reflect the value of the support and service you get from the service provider.

Software development has been the biggest concern in the prepress business for a long time and for decades we’ve been reasonable happy to pay for it. That might be because people didn’t fully understand the workings and nuances of what they were buying. After all, it’s not possible to price software by the litre or the square metre as can be done with substrates, ink and plates. But these days software advances and innovations are taking a back seat to advances in both printing plates and inks, to materials science which is also helping bring down print’s environmental impact.

A glance at the trade press will tell you materials science is definitely where all the action is. It’s easy to compare plates and inks like for like so price squabbles seem to be more common than they used to be. Bickering over the price of plates, ink or substrates is simpler with tangible materials for which the pricing should not be opaque or confusing. Materials are easier to compare than software products, but we should keep in mind that for both materials and software the cost of research and development (R&D) is built in. It was a given with software that you pay for the development of upgrades and functionality improvements and the same is true for plates, inks and substrates, especially if those improvements drive down the industry’s carbon footprint. So be prepared to pay a little more to ensure the continued evolution of the materials you buy. R&D is the only way our industry will keep evolving and moving forward, whether it’s the development of preflight software, or an as yet uninvented imaging system.

Topics

Recent news

Kodak's 2024 Sustainability Report: A Commitment to a Greener Future

Kodak's 2024 Sustainability Report, "One World, One Kodak," demonstrates a strong commitment to environmental and social responsibility. The report highlights impressive reductions in greenhouse gas emissions (56%) and water withdrawal (31%) and aims for zero waste by 2025. Notably, Kodak is pioneering double materiality assessment in the printing industry, aligning sustainability with financial reporting, and showcasing its products' environmental benefits.

How can printers lower costs on energy usage?

Clare Taylor outlines simple steps for businesses to achieve energy sustainability, focusing on cost savings and staff comfort. It emphasises starting with measuring energy consumption to identify key areas for improvement. Subsequent steps involve managing energy use through behavioral changes and low-cost interventions, like optimizing cooling settings and ensuring equipment is switched off when not needed.

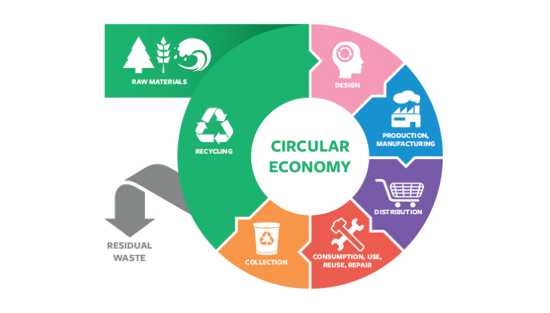

The European Union's circular economy plan

Printing companies must understand the EU's Circular Economy Action Plan (CEAP), part of the European Green Deal. These initiatives drive sustainability, impacting businesses globally, even if not EU-based, through customer requirements. Printers need to be aware of reporting and sustainability expectations to manage risks and retain clients.

A revised look at sustainability in wide format print

Sustainability is crucial for wide-format print, moving beyond marketing to an imperative driven by brands and regulations. Common "eco" claims often mask complexities; true sustainability demands carbon reduction as a core principle. Life Cycle Assessment (LCA) offers data-driven insights for genuine environmental improvement, as demonstrated by UFABRIK's transparent approach.