What are the best sustainable fibre types for use in printed sportswear?

Sam Taylor from The Good Factory discusses the latest and most suitable fibre types that can be used in printed sportswear such as bio plastics. Sam also discusses whether using recycled PET bottles for clothing is greenwashing or not.

The question of whether using recycled PET bottles for clothing is greenwashing is becoming louder. Honestly, it’s a difficult one to answer. When the EU were creating the new circularity legislation, a number of FMCG brands attempted to push the EU to give them priority for rPET over that of fabric businesses. Simply put, there is a higher recycled content in your fabric than in the plastic bottles. A large part of that comes down to price, and supply and demand. Chippers get more money from companies wanting to make it into yarns than bottle companies. Because fabric holds more value in society than bottles. The EU decided not to factor that request into legislation. But brands should expect push back from companies that wish we didn’t create demand for a rPET in the first place!

A plastic alternative that has been built into the EU legislation is bio plastics. These are plastics made from renewable resources such as castor bean oil and sugar molasses etc. Each of these fabrics has benefits and drawbacks compared to standard synthetics. Generally they require lower temperatures to print, creating energy savings, but they are a little more temperamental when it comes to matching to colour standards. We’ve been printing polyester and poliamide so long it’s second nature, and this will become easier the more we do it.

An exciting new development for the sportswear industry comes from BASF Chemicals in the form of a fully circular polyamide 6 called Loopamid, made entirely from textile waste. This is a relatively new development so we’re still a way off from this being a mainstream yarn. But we know that drop in solutions such as this, where no changes to equipment or process is needed, will make it easier to grow circular solutions. Similarly is synthetics made from carbon capture technology, while this is mostly used by the packaging industry at present, both Primark and H&M have debuted ranges using polyester from this technology which is likely to bring it into the mainstream.

Thanks to Lululemon’s new fabric Nulu, many brands are searching for that buttery soft handfeel again. While Nulu is made from a nylon / elastane blend, many brands go to semi synthetic materials such as viscose or bamboo to get the same handfeel. Again, different feedstocks do have some variation on how they perform. Viscoses made from bamboo or eucalyptus have better anti bacterial properties than those made from pines, but better moisture management comes from cellulosics made from textile waste such as Refibra which is made from Renewcell pulp.

When it comes to natural fibres the best sportswear solution is wool, but to ensure a good print quality the fibres and yarns have to be processed differently which usually requires a higher MOQ for. Given the range of feedstocks being offered as sustainable solutions to virgin petroleum based synthetics, we’re unlikely to see prepared fpr print wool bases making it into the mainstream.

To see a selection of these fabrics head over to the Sustainability Spotlight!

Visit the Sustainability Spotlight stand and discover the latest sustainable innovations in print at FESPA Global Print Expo 2024, Europe’s leading print and signage exhibition. To discover the latest innovations in sportswear at Sportswear Pro 2024. Sportswear Pro will showcase the very latest technologies and solutions for on-demand and customised sportswear production. Both exhibitions will be taking place from 19th – 22nd March 2024 at the RAI Amsterdam in Netherlands. To visit register here.

Topics

Recent news

Kodak's 2024 Sustainability Report: A Commitment to a Greener Future

Kodak's 2024 Sustainability Report, "One World, One Kodak," demonstrates a strong commitment to environmental and social responsibility. The report highlights impressive reductions in greenhouse gas emissions (56%) and water withdrawal (31%) and aims for zero waste by 2025. Notably, Kodak is pioneering double materiality assessment in the printing industry, aligning sustainability with financial reporting, and showcasing its products' environmental benefits.

How can printers lower costs on energy usage?

Clare Taylor outlines simple steps for businesses to achieve energy sustainability, focusing on cost savings and staff comfort. It emphasises starting with measuring energy consumption to identify key areas for improvement. Subsequent steps involve managing energy use through behavioral changes and low-cost interventions, like optimizing cooling settings and ensuring equipment is switched off when not needed.

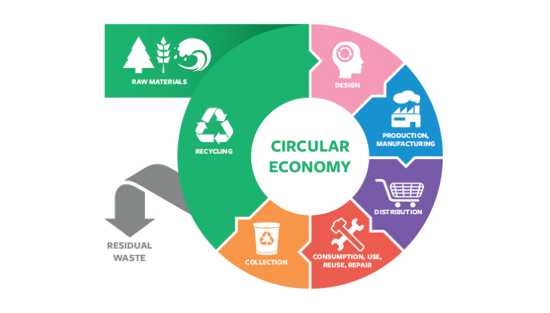

The European Union's circular economy plan

Printing companies must understand the EU's Circular Economy Action Plan (CEAP), part of the European Green Deal. These initiatives drive sustainability, impacting businesses globally, even if not EU-based, through customer requirements. Printers need to be aware of reporting and sustainability expectations to manage risks and retain clients.

A revised look at sustainability in wide format print

Sustainability is crucial for wide-format print, moving beyond marketing to an imperative driven by brands and regulations. Common "eco" claims often mask complexities; true sustainability demands carbon reduction as a core principle. Life Cycle Assessment (LCA) offers data-driven insights for genuine environmental improvement, as demonstrated by UFABRIK's transparent approach.