Ukranian printing company invests in Flexcel NX Wide

Ukrpol, a Ukranian printing house that focuses on commercial printing and packaging production has a wide array of customers that are in the food, cosmetics and medical sectors. The company recently bought a Miraclon Flexcel NX Wide 4260 flexographic platemaking system. This purchase will help the company attract customers who acknowledge the value of modern flexo for packaging production.

The story of Ukrpol is one not just of survival during times of strife. This Ukrainian printing house has, through judicious technology investments, more than thrived since its founding in 1997. Today Ukrpol has over 23,000m2 of production space and employs almost 600 people at its two factories in Stryi, in the west of Ukraine near to Lviv.

Ukrpro started life as a commercial printer, but has been moving into packaging production for a number of years. The company produces packaging for leading brands in a wide range of sectors, mainly food, pharmaceuticals, cosmetics and household products. Over the years, Ukrpol has become a Ukrainian printing industry leader, with almost 30% of its output is exported. The company has customers in Germany, Belgium, Poland, Sweden, the Czech Republic and the Dominican Republic.

Ukrpol’s latest new kit is Miraclon’s Flexcel NX Wide 4260 flexographic platemaking system. Bringing wide-web flexo platemaking in-house has been part of a wider investment into Ukrpol’s production systems. The Flexcel kit complements a newly installed 670-mm wide press and a 1300-mm press due to come online soon. Ukrpol has set up a completely new dedicated flexo facility at the company’s plant in Stryi.

Packaging production is one of the few, if not the only, print application that is immune to digitisation. Every other form of communications dominated by print, can be replicated online. True the experience isn’t quite the same but the end result generally is. Not so with packaging, so it’s unsurprising that so many commercial printers are upping their packaging production game. And it is why we see so many printers offering their customers a range of production options, especially for short packaging print runs. To support this part of its business Ukrpol has been moving into flexo production for several years, although gravure and offset still accounts for 70% of the company’s production volume. Flexo and digital printing account for 25% and 5% respectively.

Matching the demands of a print application to the available technology is fundamental if you want to ensure production efficiency and get a positive hit to the bottom line. Some applications, such as short run production are better met with digital printing for instance. Over the years as technology improves, the efficiency equations change and modern flexo is increasingly suitable for packaging jobs previously destined for a gravure press.

Market realities also play a role as this transition progresses. Turnaround times are getting tighter, run lengths are coming down and brand owners are increasingly concerned with maximising shelf-time. They are no longer happy with a six week transition time for getting new products to the shelf. Brands also have concerns about the sustainability of the gravure printing process. Modern flexo printing is even more attractive in this context, so Ukrpol is confident that it can capitalise on its Flexcel NX investment. The new kit will help Ukrpol to attract customers who recognise the value of modern flexo for packaging production.

Topics

Recent news

Kodak's 2024 Sustainability Report: A Commitment to a Greener Future

Kodak's 2024 Sustainability Report, "One World, One Kodak," demonstrates a strong commitment to environmental and social responsibility. The report highlights impressive reductions in greenhouse gas emissions (56%) and water withdrawal (31%) and aims for zero waste by 2025. Notably, Kodak is pioneering double materiality assessment in the printing industry, aligning sustainability with financial reporting, and showcasing its products' environmental benefits.

How can printers lower costs on energy usage?

Clare Taylor outlines simple steps for businesses to achieve energy sustainability, focusing on cost savings and staff comfort. It emphasises starting with measuring energy consumption to identify key areas for improvement. Subsequent steps involve managing energy use through behavioral changes and low-cost interventions, like optimizing cooling settings and ensuring equipment is switched off when not needed.

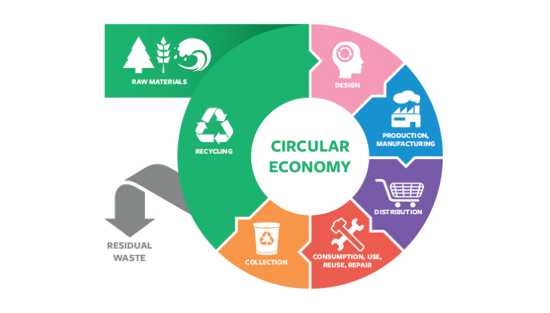

The European Union's circular economy plan

Printing companies must understand the EU's Circular Economy Action Plan (CEAP), part of the European Green Deal. These initiatives drive sustainability, impacting businesses globally, even if not EU-based, through customer requirements. Printers need to be aware of reporting and sustainability expectations to manage risks and retain clients.

A revised look at sustainability in wide format print

Sustainability is crucial for wide-format print, moving beyond marketing to an imperative driven by brands and regulations. Common "eco" claims often mask complexities; true sustainability demands carbon reduction as a core principle. Life Cycle Assessment (LCA) offers data-driven insights for genuine environmental improvement, as demonstrated by UFABRIK's transparent approach.