The search for sustainable packaging

Nathan Tiller from CarbonQuota the ongoing war on plastic and other sustainable, fibre-based innovations. Life Cycle Assessments offer an objective view of the advantages and disadvantages of different materials.

Six years ago the Ellen MacArthur Foundation (EMF) estimated there would be more plastic by weight than fish in the sea come 2050. Five years ago that BBC Blue Planet series was aired. And two years have passed since campaigning chef Hugh Fearnley-Whittingstall’s War on Waste.

Plastic, we are told time and again, is (very) bad. Which makes everything else (very) good, right? If only decisions on sustainability were that simple. As Gartner, a consultancy, noted in a recent blog: “The reality of sustainable packaging is that it’s complicated.”

There is no magic packaging; no sustainable silver bullet. But that hasn’t stopped that simple narrative on single-use packaging (quickly) evolving to suggest as much. As plastic is pilloried brands – keen to do something in the face of considerable pressure from the public and politicians – have swung to other materials.

Aluminium, fibre, compostable and other novel materials have all benefitted. Sausages are being put in cardboard. Beer is in bottles made of paper. And milk has been moved from (recyclable) plastic bottles to (harder to recycle) cartons. Whether these are sustainable choices, moves led by marketing or well-intended but ultimately poor decisions with unintended environmental consequences is moot.

Green Alliance, a think tank, warned in 2020 how grocery brands were reporting that decisions to switch away from plastic are often made without considering the environmental impact of the substitute materials chosen, or whether or not there is adequate collection and treatment infrastructure in place for them. One of the industry leaders consulted for the research called the process “fairly quick and fairly cut and dry”, prompted by a mandate to office managers to “be more environmentally friendly” which results in “a kneejerk reaction to exit plastic”.

Plastic’s pain is paper’s gain

Paper has been a principal beneficiary of the war on plastic. Mintel figures show paper and board packaging accounts for the largest share of the food packaging market, rising from 49% in 2018 to a projected 54% in 2022. The direction of travel will continue to be replacement of plastic with fibre packaging, according to other forecasters.

Paper certainly resonates well with the public, often scoring highly well in polls showing the public’s perception of different packaging. There have also been surveys showing how compostable, aluminium and glass are also ‘favourites’. The one consistent constant is that plastic is often left languishing at the bottom of any table – even if it is recyclable or made from recycled content.

To be clear, mine is not a pro-plastic stance; rather it is an acceptance that the reality is far more nuanced – which can leave consumers and companies struggling to keep up with this rapidly evolving area.

As research published in the journal Resources, Conservation and Recycling in June 2022 noted: “[…] if neither theorists, nor companies, nor government agree on the sustainability of different types of packaging – how are consumers supposed to make correct assessments?” Experts from Germany and the Netherlands have also assessed how consumers evaluate food packaging by affective feelings rather than using cognitive reasoning. Their paper detailed how people’s perceptions of different packaging materials don’t often align with the scientific reality – and that means their buying behaviour “is in most cases less environmentally sustainable than intended”.

Your customers will therefore be looking at you to cut through this fog. Initially, brands achieved this by simply switching out of plastic. As one brand moved so others followed, a shift that Gartner refers to as the “hype cycle for sustainable packaging”. Targets were also set, voluntary agreements penned and budgets re-ordered. In recent months some have started to realise these packaging promises will be hard to meet: some financial, technical, operational and environmental hurdles are proving hard to jump.

Targets set by those signing up to the EMF’s global plastic commitment are now unlikely to be achieved by 2025. Those in the UK version, the Plastics Pact run by charity Wrap, are making progress in some areas but struggling in others. One of the problems remains flexible plastic packaging.

The softer the plastic is, the harder it is to recycle. Processing flexible plastic packaging – think bread bags, crisp packs and sweet wrappers – back into materials fit for food contact is even harder. Companies therefore continue to turn to paper. But is this seemingly simple switch actually sustainable?

Pulp fiction (and facts)

There have been a slew of fibre-based innovations across FMCG of late, with the likes of Heinz, Diageo, Mars and Nestlé all making moves. Mars for example uses a lot of flexible plastic packaging, which it notes is safe, convenient and reduces carbon more than many forms of currently reusable, recyclable or compostable packaging. However, it is not readily recyclable, which makes it an easy target for NGOs. In Australia, the company has therefore started rolling out ‘fibre-based’ packaging for products like Snickers and Milky Way.

Whether this kind of packaging is “more sustainable” as some brands claim is not quite clear. Often it comes with a very thin plastic lining that recyclers can find hard to separate. Barrier coatings can present similar issues for paper mills. Sandwich wrappers, insulated food delivery packaging, coffee bags and soft drink cups from fast food outlets are clogging up paper mills, according to packaging firm DS Smith. The Confederation of Paper Industries says 2% (equating to 120,000 tonnes) of the packaging that arrives in its members’ mills is “more challenging” to recycle. CPI They wants to see no more than 5% of the packaging by weight to be plastic, which is lower than the limit set by the On Pack Recycling Label to achieve a ‘recycle’ label.

Another example is coffee cups, which also have a plastic liner. The 3.2 billion (35,000 tonnes) of them used every year could actually be recycled (there’s enough capacity) but only 2.8% are, according to Wrap. Recent analysis also showed 3.2 billion fibre-composite food containers are consumed every year but there is “no treatment or recycling infrastructure in place”. These statistics remain in the shadows with the spotlight trained firmly on plastic.

With bans on certain single-use plastic containers already in force in Scotland and coming into force in England and Wales soon, more companies will turn to paper. They need to be wary of the potential consequences of this – and not just in terms of paper’s recyclability. “[…] companies who are making the necessary shift from plastic but are choosing to replace that with paper packaging are trading one environmental disaster for another,” Tamara Stark, from forest conservation network Canopy, told Packaging Insights recently.

Carbon and chemicals

Paper may have had a free ride on the back of plastic’s demise but scrutiny is increasing over links with deforestation, water consumption levels and pollution risks. Expect the use of PFAS – or ‘forever chemicals’ – which improve moisture resistance of paper and board packaging to come under fire too.

The reliance on virgin fibre in food packaging has also largely gone unnoticed. WWF is among the NGOs to have warned that “trends to replace oil-based plastic with wood-based plastic, will only increase the pressure on forests”. Determining whether paper packaging is sustainable or not is complex, as Innovation Forum has detailed.

Again, this isn’t to pan one packaging type and promote another. Plastic has well-known issues relating to pollution, and there are considerable concerns about how the chemicals used in packaging flow in recycling loops. Research in the US for example has warned that “the circular nature of the recycling economy may have the potential to introduce additional chemicals into products”.

All of this makes it incredibly hard for companies to develop a coherent strategy on packaging. Consumer preferences, regulations and technology are all shifting – and any changes must be viewed through the lens of your net-zero trajectory.

Increasingly, companies are relying on Llife Ccycle Aassessments (LCAs) to provide an objective view of the pros and cons of different materials. LCAs have their limitations but, done well with reliable and representative data, they can provide meaningful outcomes.

They can also be done badly of course and there are understandable (and increasing) concerns about the use of LCAs to greenwash both consumers and companies. As Footprint research has indicated, customers take more clues about a brand’s sustainability initiatives from the packaging than they do about anything else so the temptation to mislead or look for simple solutions is strong. Unfortunately those looking for silver bullets could end up shooting themselves in the foot.

Indeed, research by PwC shows that switching all current consumption of plastic packaging

(1.6 million tonnes) on a like-for-like basis, to the other materials currently used for packaging in the UK could almost triple associated carbon emissions from 1.7 billion tonnes of CO2e to 4.8 billion tonnes of CO2e. That, the authors warned, doesn’t mean we should continue using plastic as we have but that we need to address the root problems of our throwaway culture. Material use, impacts and waste all need to be reduced because there isn’t one piece of disposable packaging that can boast zero impact.

Plastic has been cast as the villain but the credentials of the heroes looking to replace it need challenging too.

For more information on CarbonQuota and their services please visit here: https://www.carbonquota.co.uk/

Topics

Recent news

Kodak's 2024 Sustainability Report: A Commitment to a Greener Future

Kodak's 2024 Sustainability Report, "One World, One Kodak," demonstrates a strong commitment to environmental and social responsibility. The report highlights impressive reductions in greenhouse gas emissions (56%) and water withdrawal (31%) and aims for zero waste by 2025. Notably, Kodak is pioneering double materiality assessment in the printing industry, aligning sustainability with financial reporting, and showcasing its products' environmental benefits.

How can printers lower costs on energy usage?

Clare Taylor outlines simple steps for businesses to achieve energy sustainability, focusing on cost savings and staff comfort. It emphasises starting with measuring energy consumption to identify key areas for improvement. Subsequent steps involve managing energy use through behavioral changes and low-cost interventions, like optimizing cooling settings and ensuring equipment is switched off when not needed.

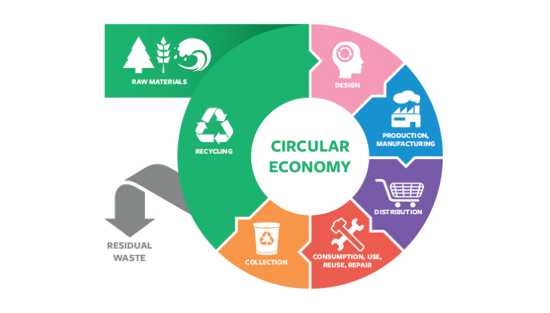

The European Union's circular economy plan

Printing companies must understand the EU's Circular Economy Action Plan (CEAP), part of the European Green Deal. These initiatives drive sustainability, impacting businesses globally, even if not EU-based, through customer requirements. Printers need to be aware of reporting and sustainability expectations to manage risks and retain clients.

A revised look at sustainability in wide format print

Sustainability is crucial for wide-format print, moving beyond marketing to an imperative driven by brands and regulations. Common "eco" claims often mask complexities; true sustainability demands carbon reduction as a core principle. Life Cycle Assessment (LCA) offers data-driven insights for genuine environmental improvement, as demonstrated by UFABRIK's transparent approach.