3D-Printing: Software Matters

3D printing hardware has become much more reliable and affordable, this has turned the attention to 3D printing software to enable a more effective workflow. Sonja Angerer shares the latest product offerings.

3D printing has turned into a profitable segment for some printers, especially since so many other business options have deteriorated within the last two years. Hardware manufacturers like HP or Mimaki, already well-known in the wide-format industry, have been offering turn-key solutions for 3D prints. However, changing over from 2D data to printing in 3D, can be challenging. Today’s software helps to make workflows quick and painless, even for people with limited experience in 3D printing.

How different is 3D print data from 2D print data?

When it comes to print data delivered by their customers, printers have been able to take advantage of the huge progress that has occurred in technology. In the early years of Desktop Publishing (DTP), open formats such as .qxp were the norm, leading to all kinds of font and picture-related problems. Today, most customers upload a PDF-X or at least any PDF format. Therefore, minimal tweaking is required for print, and many workflows are automated.

Handling 3D data is a main problem for many printers who would like to branch out into the segment. The data structure can be quite complex, this can result in the overall data quality delivered by customers being poor. Also, there’s still not just one widely accepted 3D data format for print. In fact, some of the most common 3D print formats are:

- STL (many consider it today´s de-facto standard)

- OBJ

- AMF

-

3MF

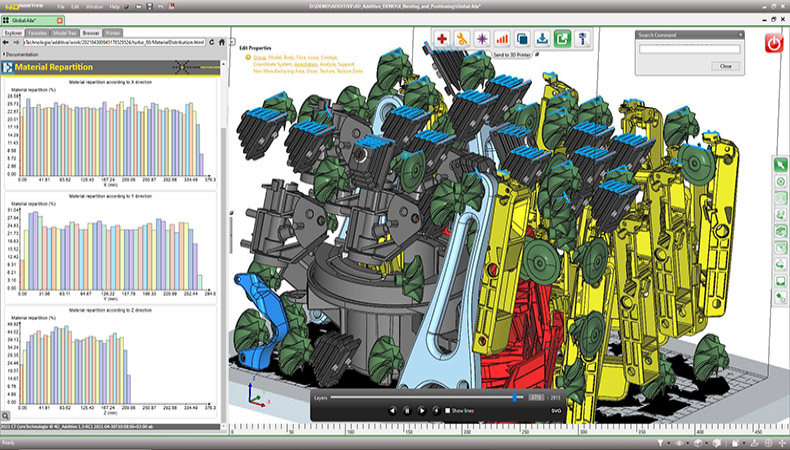

Caption: 4D_Additive the software is able to read 3D models from all common CAD formats and prepare them for additive manufacturing processes. Screenshot by CT CoreTechnologie GmbH

Caption: 4D_Additive the software is able to read 3D models from all common CAD formats and prepare them for additive manufacturing processes. Screenshot by CT CoreTechnologie GmbH

What is 3D printing workflow?

The 3D printing process begins with a 3D model, this is a description of the object to be printed. It describes the objects surface, shape, dimensions as well as optional details such as internal structure, materials, colour, or texture. 3D models can be created using a variety of software programs, such as CAD software or 3D modelling software.

The 3D model needs to be converted into a format that the 3D printer can understand, this is done using slicing software. Slicer software needs a host of information about the printer and the properties of the material used, as well as information about the intended output quality or support structures needed.

A G-Code file contains toolpath information, basically instructing the 3D printer what to do. As errors at any stage of the process will jeopardize or significantly delay print output, there is a range of STL repair software available. The best known one being Microsoft 3D Tools. Tweaking customer data for 3D can take longer than expected, therefore increasing prices. In a highly competitive environment, this can quickly become a problem for printers.

Caption: In the building industry, printed 3D models have become very popular. Image credit: Mimaki.

Caption: In the building industry, printed 3D models have become very popular. Image credit: Mimaki.

Mimaki 3D Print Prep Pro software streamlining workflows

The new Mimaki 3D Print prep Pro software is designed to streamline and optimize 3D model production. This cloud-based software offers increased automation, making it easier to create 3D prints. This makes it less of a challenge to produce high-quality, full-colour prints.

It is compatible with all Mimaki 3DUJ-series printers. Designed to simplify the 3D printing process, the new platform helps prepare and finalize 3D files before printing. This cutting-edge subscription-based software autocorrects file errors and optimizes 3D data used in 3D printer modelling. Ensuring that the final 3D printed objects look exactly the same as the ones visualized on the screen.

Caption: 3D shop window decoration for Easter: Lindt Goldhase 70th anniversary edition. Image credit: S. Angerer

Caption: 3D shop window decoration for Easter: Lindt Goldhase 70th anniversary edition. Image credit: S. Angerer

4D_Additive: Universal 3D Software

With its latest version 1.3 of 4D_Additive the software by CT CoreTechnologie GmbH is able to read 3D models from all common CAD formats and prepare them for additive manufacturing processes.

For the first time, the new version has an application interface (API) available. This allows Hewlett Packard printers to send the slicing data generated on the computer directly to the printer, as you can imagine, this saves a lot of time. The new textures module can enhance CAD-generated and STL models quickly and easily with surface textures.

Improved nesting functions ensure fast and thermally optimized filling of the print bed with the help of AI. The graphical user interface (GUI) is easy to operate even for newcomers as the workflow for the preparation of 3D parts for additive manufacturing is organized in the form of sequential workshops.

Is software the new hardware when it comes to 3D printing?

3D printing is becoming more popular. This is because it is becoming easier to produce high-quality, full-colour prints using this technology. To take advantage of this and make professional 3D printing even easier, consider state-of-the-art prepping software. Cutting-edge software autocorrects file errors and optimizes customer 3D files for quick and painless printing. It also helps to setup an effective 3D printing workflow.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

How to grow your business with white ink applications

Opaque white ink is revolutionising signage, vehicle graphics, wallcoverings, short-run and wood packaging, and window blinds by enhancing vibrancy and clarity. This enables printers to offer high-demand, standout products, boosting profit margins. HP Latex white ink applications and their large format printing solutions will be showcased at FESPA 2025 in Berlin.