Zünd releases Cut Center 3.0 software suite

Zünd has added new functionality to its Cut Center production planning and job management software.

Zünd is introducing Version 3.0 of its comprehensive Zünd Cut Center – ZCC software suite, which is designed to offer additional and enhanced registration methods for even greater productivity, as well as an added, browser-based dashboard for remote access to all performance and production data.

The company has expanded its suite with new functionalities and another boost in performance and user-friendly operation. The new release includes a variety of intelligent workflow options. Additional registration methods are said to generate significant increases in overall productivity.

Version 3.0 now includes refined algorithms for capturing only those register marks essential for accurately determining position, skew and distortion. Consequently, the ICC camera targets only critical marks for capture, translating into productivity gains.

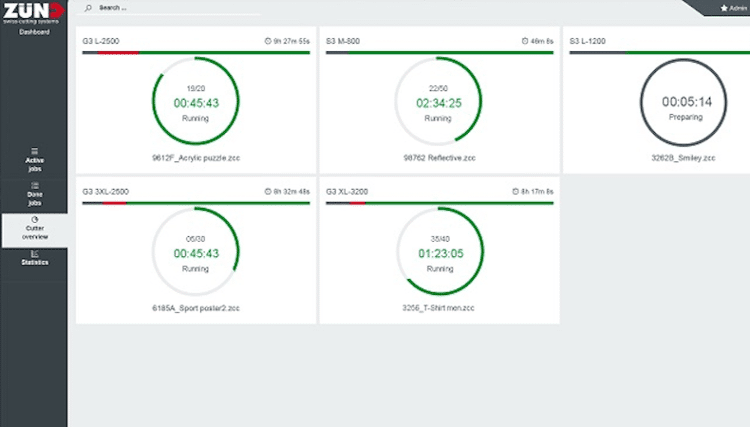

Dashboard is another highlight of the latest version of Zünd Cut Center. This new browser-based function visualises performance and productivity data of the Zünd cutters operating on the production floor.

Dashboard gives management and production staff easy, round-the-clock remote access to all relevant production data. Real-time job status can be viewed anytime, anywhere. Visualised statistics provide a clear, instantaneous overview of Zünd cutter productivity for user-definable time periods.

Quality and productvity

“Organisation and clarity are the be-all and end-all of smart production planning. That is exactly what Zünd's proven Cut Queue offers, with a tool palette that facilitates production planning and job management,” the manufacturer explains.

Cut Queue estimates production times and facilitates setup by visualising job contours. Many settings, such as overcut compensation and offsets for objects and cut paths, can either be handled automatically through hot folders or manually, at any time, via Cut Editor.

Hot folders automatically generate production-ready files from commonly used layout and CAD programs. This accelerates file prep and eliminates manual steps in job setup.

At the same time, the software also automatically optimises cut data for the shortest possible processing time by determining the optimal cut direction, cut sequence and cut path, closing open contours, smoothing curves, etc.

Cut Editor also provides such useful functions as crease-counter generation for high-quality creasing, powerful nesting features for maximum material yield, and a variety of routing features.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Industry Experts Explore the Evolution of Smart Manufacturing in the Textile Industry

A FESPA SmartHUB roundtable at Personalisation Experience 2025 discussed smart manufacturing's transformative impact on the textile industry. Experts highlighted the shift to on-demand customisation, driven by digital printing, data analytics, and automation. Key takeaways included enhanced machine control, significant waste reduction through intelligent software and colour management, and improved sustainability via energy efficiency and near-shoring, ensuring agility and environmental responsibility in textile production.

FESPA 2025 gathers leading visionaries from across the speciality print industry in Berlin

FESPA Global Print Expo 2025, European Sign Expo and Personalisation Experience (6 – 9 May 2025, Messe Berlin, Germany) welcomed Visionaries from across the speciality print industry to shape the future of print, develop forward-thinking business strategies, and explore innovative ways to translate emerging industry trends into tangible growth opportunities.

Exploring Cutting-Edge Textile Printing Innovation with Adobe Print Engine 7

Adobe PDF Print Engine 7, launched at FESPA Global Print 2025, significantly advances textile printing. Debbie McKeegan shares how it automates non-white substrate management and RGB colour handling, expands colour gamuts with in-RIP multicolour transparency blending, and streamlines workflows for efficiency and sustainability. This update boosts customisation, reduces waste, and positions businesses at the forefront of digital print innovation.

FESPA Global Print Expo 2025 - Overall Highlights

FESPA Global Print Expo, Europe's leading print and signage exhibition returned to Messe Berlin from 6 - 9 May 2025.