X-Rite and Pantone build colour measurement partnership

X-Rite and its subsidiary Pantone LLC have joined forces with ColorPartner to help automate colour management for industrial inkjet applications.

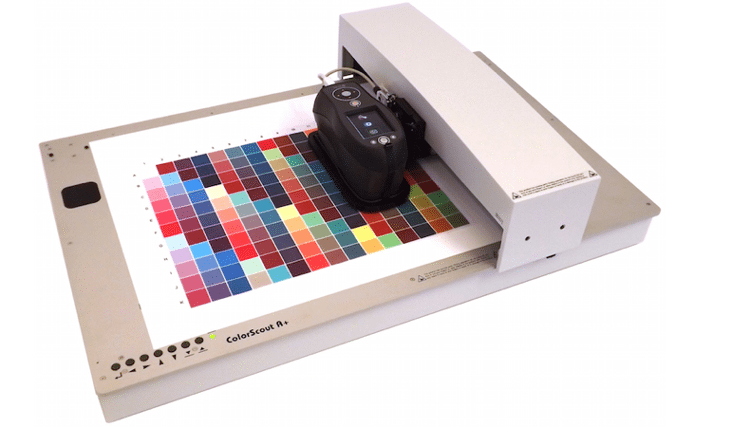

The new offering combines the ColorPartner ColorScout A+ automated colour measurement table and X-Rite’s Ci6x family of sphere spectrophotometers to enable printers to better measure colour on metallic, wood, plastic, ceramic and textured materials.

The new Ci6X/ColorScout A+ solution will be made available through a variety of RIP manufacturers that support industrial inkjet output devices.

“Inkjet technology makes it possible to print on a wide variety of materials, opening up new opportunities to industrial and commercial printers from fast fashion to flooring to packaging to home décor,” said X-Rite vicepresident Jan Keller.

“With higher material costs, printers cannot risk color errors that may be inherent in a manual measuring process. The Ci6x/ColorScout A+ solution eliminates these potential errors and can quickly and easily pay for itself by ensuring less waste due to color issues, increasing profitability and speeding time to market for brand owners and manufacturers alike.”

As the market moves to greater use of industrial inkjet, there is a growing need for an automated measurement solution that can quickly measure color across flat, textured and reflective surfaces. The 45/0-based measurement devices used in graphic arts applications are ideal for smooth or matte surfaces but have limited capabilities for textured or reflective materials.

The Ci6x/ColorScout A+ solution, in A3+ size (other standard sizes: A2+, A1+; others on request) accommodating materials up to 515mm by 310mm (20.3 x 12.2 inches) and up to 30mm (1.18 inches) (60mm (2.36 inches) optional) thick, is ideal for measuring color on surfaces that do not perform well with a 45/0 spectrophotometer.

As a sphere spectrophotometer, the Ci64 can accurately measure smooth, matte, reflective or uneven surfaces such as metallics, special effect finishes and textures commonly used in industrial inkjet applications from small label printing to LFP. Integration with color RIPs through X-Rite’s software development kit (SDK) will enable better color calibration and profiling of industrial inkjet printing and deposition solutions.

In addition to being more reliable, the Ci6x/ColorScout A+ solution saves precious time in busy production environments. X-Rite tests reveal that it measures up to twice as fast as manual measurements, saving as much as an hour per 1,000 measurements.

“The Ci6x/ColorScout A+ solution is truly rare in the market, as it incorporates a sphere spectrophotometer to handle thick and textured materials, as well as reflective surfaces,” said Ingmar Brumm, Managing Partner, ColorPartner. “This will help packaging converters and industrial manufacturers achieve consistent color faster and with more repeatability.”

Jay Larsen of INX International, a manufacturer of inks for conventional and inkjet printing, was an early user of the solution, integrated with a CGS RIP. According to Larsen, “the biggest benefit is the time savings and the repeatability of the measurement. The unit is very well engineered and well built - which should result in years of useful service.”

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

How to grow your business with white ink applications

Opaque white ink is revolutionising signage, vehicle graphics, wallcoverings, short-run and wood packaging, and window blinds by enhancing vibrancy and clarity. This enables printers to offer high-demand, standout products, boosting profit margins. HP Latex white ink applications and their large format printing solutions will be showcased at FESPA 2025 in Berlin.