Vinehall Displays keeps operating during lockdown

Dublin-based Vinehall Displays was the first company in Ireland to take delivery of a swissQprint Nyala 3 flatbed printer in late 2019. What the business could not have predicted at the beginning of 2020 was how significant its investment would become when, without warning, the Coronavirus would sweep across the world and drive individuals into their homes as social distancing measures were implemented across the world.

Very few manufacturers have proven immune to effects of the COVID-19 pandemic. For some, the world has been turned upside down and production has ground to a halt, while others have switched to new products to survive.

Vinehall Displays is a family-run conference, exhibition and event production company with a 32-year pedigree specialising in the design, build and delivery of promotional materials for a broad range of blue-chip, multinational companies. During the early stages of the Irish lock-down, the management at Vinehall Displays had a choice. It could either shut its doors and hope for events to restart soon, or use its manufacturing strength and highly skilled workforce to move into new markets.

Challenge taken

The company’s response was to create a range of cost-effective workstation solutions for people who were faced with suddenly having to work from home. “Many people were trying to figure out how to find a dedicated and comfortable spot to work while sharing small spaces with other family members,” says company director Gerard McElhinney.

“Our view was that this shift towards having a “home office” would become the new way of working for a while, and it became increasingly clear that many of us aren’t properly equipped to do so,” he says. Vinehall Displays then set about designing and building a number of products such as a laptop stand, a simple lap desk, or even a sturdy flat pack workstation that could be sold online via a storefront that was added to the company website.

Immediate success

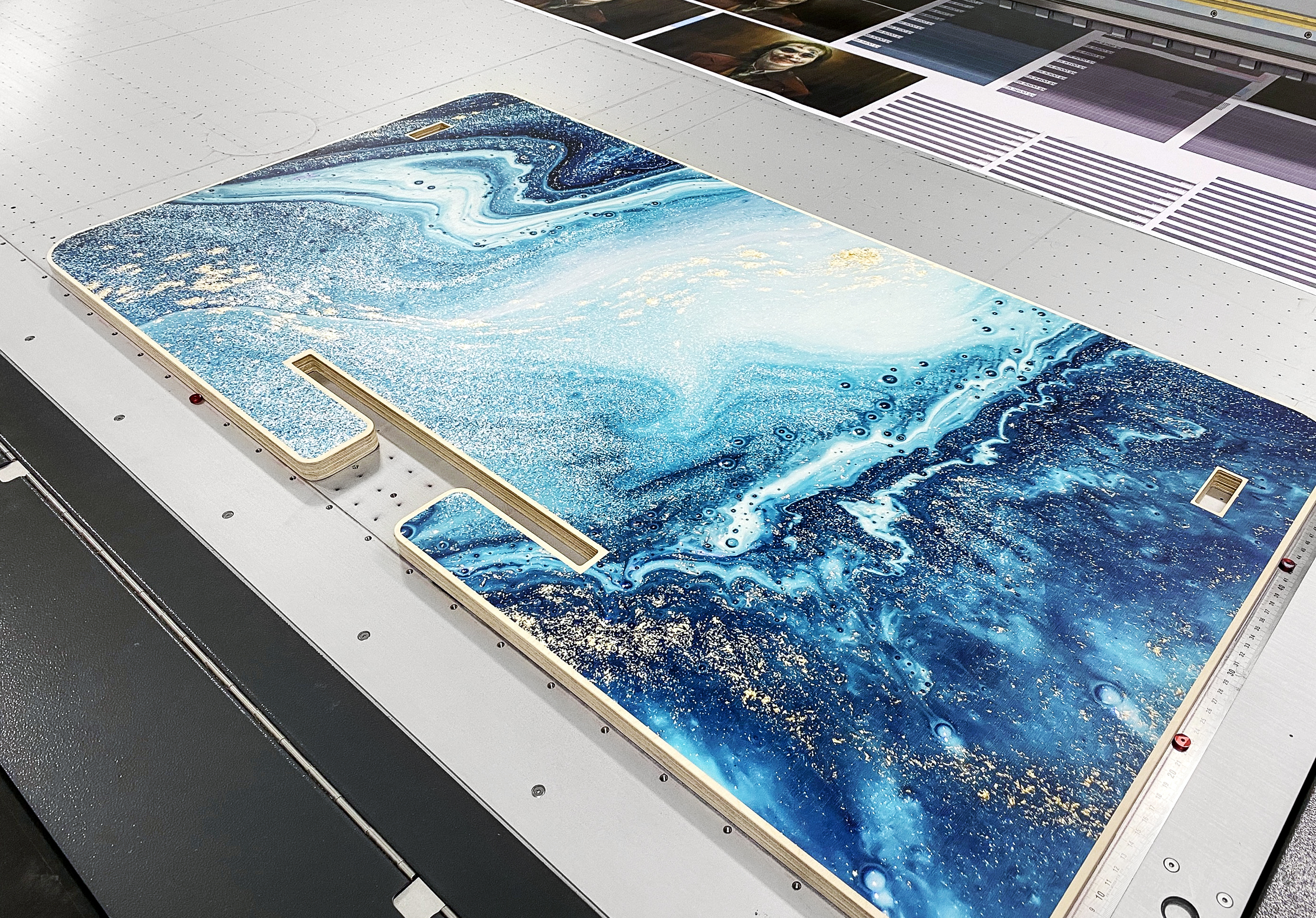

Manufacturing the products would be relatively straightforward as the company already had a CNC router to cut patterns made from untreated furniture grade European FSC certified birch plywood, and because it could print directly onto the wood using its swissQprint Nyala 3, a range of custom printed worktops could be made available. The products were then promoted across social media channels. “We gained an immediate amount of social media traction with one of our laptop stands,” explains Mr McElhinney. “A social media influencer ordered one and liked it so much that he shared it on Twitter. We subsequently picked up 150 orders from that single engagement.”

Exercise From Home range

The company has since extended its range of online Work From Home products with the addition of a child’s desk/play-centre. It has also recently launched an ingenious range of Exercise From Home products which include plyometric boxes with fully custom-branded 3-in-1design, a custom printed flat-pack weight lifting bench, printed slant/squat boards, and a personalised adjustable bicycle stand. Other innovations include fully customised and branded acrylic desk dividers and safety screens designed to compliment existing interiors.

Crisis used as gamechanger

The Vinehall Displays online store was born out of the necessity for change and innovation during the Covid-19 pandemic. It has meant that the company has been able to keep the doors open during the lockdown and to keep all of the skilled workforces in employment. “None of this would have been possible had we not have invested in the equipment necessary to secure the economic future of our company,“ concludes Mr McElhinney. Thanks to the swissQprint Nyala 3 the business has been catapulted ahead to a future Vinehall Displays could not have imagined even a year ago. This goes to show that with careful and considerate economic planning, manufacturers everywhere can gain momentum and find success from identifying opportunities to diversify into new products or services, even in the face of economic adversity.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Industry Experts Explore the Evolution of Smart Manufacturing in the Textile Industry

A FESPA SmartHUB roundtable at Personalisation Experience 2025 discussed smart manufacturing's transformative impact on the textile industry. Experts highlighted the shift to on-demand customisation, driven by digital printing, data analytics, and automation. Key takeaways included enhanced machine control, significant waste reduction through intelligent software and colour management, and improved sustainability via energy efficiency and near-shoring, ensuring agility and environmental responsibility in textile production.

FESPA 2025 gathers leading visionaries from across the speciality print industry in Berlin

FESPA Global Print Expo 2025, European Sign Expo and Personalisation Experience (6 – 9 May 2025, Messe Berlin, Germany) welcomed Visionaries from across the speciality print industry to shape the future of print, develop forward-thinking business strategies, and explore innovative ways to translate emerging industry trends into tangible growth opportunities.

Exploring Cutting-Edge Textile Printing Innovation with Adobe Print Engine 7

Adobe PDF Print Engine 7, launched at FESPA Global Print 2025, significantly advances textile printing. Debbie McKeegan shares how it automates non-white substrate management and RGB colour handling, expands colour gamuts with in-RIP multicolour transparency blending, and streamlines workflows for efficiency and sustainability. This update boosts customisation, reduces waste, and positions businesses at the forefront of digital print innovation.

FESPA Global Print Expo 2025 - Overall Highlights

FESPA Global Print Expo, Europe's leading print and signage exhibition returned to Messe Berlin from 6 - 9 May 2025.