The Thought That Counts

Sonja Angerer describes how inkjet technology is ideal for printing directly on even round or irregular shaped items with no mould required.

In this day and age of the digital economy a small gift still can do much, even more so when it is personalised. Inkjet is the perfect technology to print directly onto even round or irregular shaped items with no mould required.

A flyer is thrown away in a fraction of a second. Online display advertising gets clicked away before it even builds up fully on the screen, so what can designers and marketeers do to reach their audience? Latest research papers suggest that multisensory objects achieve huge response rates. As it happens, there are three main ways for the average customer to get in contact with objects attracting more than one of his or her senses at the same time: as a personal or promotional gift, and with packaging. Basically “multi-sensory” means anything that a person can not only see, but also hold and touch, maybe even hear or taste. Bear this in mind and never wonder again why nobody seems to bother with lighters or ball-pens these days. In their small promotional gift stash, those items never make it to the end of day one at any event.

Inkjet prints direct, but contactless

.png?lang=en-GB) Caption: Promotional Gifts are very often personalised with DTO Inkjet Technology. Photo: Sonja Angerer

Caption: Promotional Gifts are very often personalised with DTO Inkjet Technology. Photo: Sonja AngererInkjet in fact has a long tradition with promotional and personal gifts, garments, shoes, cutlery, mugs and many other things, using a sublimation process. In a nutshell this means to print onto paper and transfer the water-based ink onto virtually any polyester or polyester-coated surface with the help of a high temperature press. Today’s direct-to-object (DTO) inkjet technology is faster, because the time-consuming pre-coating and transfer finishing processes are no longer required.

Always Mind The Ink

Caption: With foodsafe inks, you can even print directly onto cookies. German company “Die Kekselmacher” offers such a service. Photo: Sonja Angerer

Caption: With foodsafe inks, you can even print directly onto cookies. German company “Die Kekselmacher” offers such a service. Photo: Sonja AngererTo not destroy the printheads (and the print), they must never touch the object. This can prove to be a problem with very irregular shaped pieces. Also, the head-to-substrate distance for high quality prints is very much fixed. When the head is too far away, the colours get blurry. With a corrugated or multi-level surface, depending the result you want, any height difference bigger that about one centimetre will probably not work at all, as the ink drops cannot be placed correctly. Make sure to always order a proof print on the intended surface in the preparatory phase so that you can tweak the design or substrate as needed.

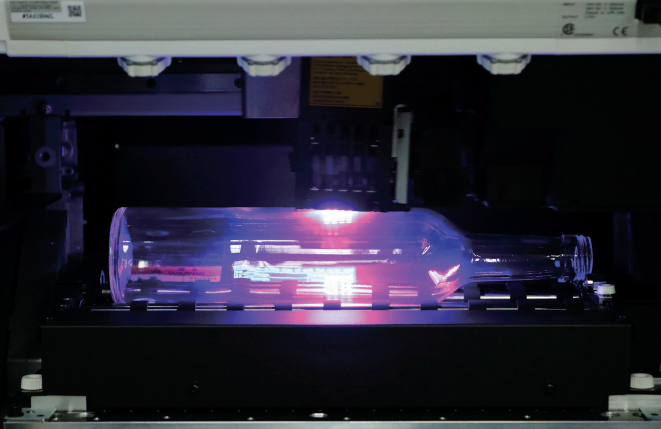

Caption: Mimaki offers a “Kebab” Option for their UJF series. Photo: Mimaki

Caption: Mimaki offers a “Kebab” Option for their UJF series. Photo: MimakiThe UV inks used in the batch printing DTO process most often are the same as a printer would use for outdoor graphics. This might not be problem when printing onto a cosmetic bag, but much more so with a mug, or anything that is intended for food or kids. But there are some low migration UV-curing inks, mainly for packaging applications (we will come back to that later). To make sure to not design a gift that harms the customer, the necessary certifications for the inks should be specified early on in the process. There are some inkjet inks that are even edible: the food industry has been working with water based, foodsafe inks for years. They are widely used for printing onto almond paste that will decorate cakes and pastries. But there also are custom-made or modified models that print directly onto cookies.

DTO Inkjet For The Packaging Industry

To offer a cost-effective tubes and cylindrical objects printing option, Mimaki has introduced “Kebab” style inkjet printing option for their UJF series. A headstock moves the cylindrical piece in front of an array of inkjet heads. With the distance between substrate and printing head constant, high-quality printing even of very small fonts is perfectly feasible. Mimaki are suggesting to print not only packaging tubes, but also vases or candles with this technology.

Personalized packaging may require a bit more productivity, though. There are dedicated direct-to-can printing options available, as well as direct-to-shape (DTS) printers that can be programmed to move the printhead safely over very difficult irregular surfaces. Those industry options usually come with an ink certified for the task, eg. low migration for primary packaging. My Muesli, a German manufacturer of customized cereals, in 2015 installed a DTS printer in their Heidelberg flagship store to offer a personalized cardboard tube box for their muesli. Industrial grade inkjet DTO/DTS solutions may however, still require relatively large quantities, as programming and finishing are time-consuming. Depending on the application, digitally printed shrink foil or even flat corrugated board that is cut with an automated Esko cutting table and assembled or folded into a box or another object may prove an alternative.

Help! My Customer wants me to DTO. What do I do now?

Relax. And make sure you understand, what exactly he or she is asking you to do: Do they want a gift or industrial good personalised? Are they looking into a unique promotional item? Do they require small batches or personal packaging? There are inkjet DTO solutions fine-tuned for each of those applications. But they need to be carefully designed and specified from an early stage: numbers, requirements, certifications … Do talk to a qualified printing house, but also to an expert in the line of business the item will be targeting. Remember there are safety regulations for almost all industrials good, and those apply to personalised as well as mass production. Then just go wild, be creative. Have fun!

The Wild Format guides are intended to expand awareness and understanding of the craziness that can be created on wide format digital printing devices, from floors to lampshades and everything in between.These guides are made possible by a group of manufacturers working together with Digital Dots. This article is supported by HP, EFI, Fujifilm, Mimaki and Roland.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Industry Experts Explore the Evolution of Smart Manufacturing in the Textile Industry

A FESPA SmartHUB roundtable at Personalisation Experience 2025 discussed smart manufacturing's transformative impact on the textile industry. Experts highlighted the shift to on-demand customisation, driven by digital printing, data analytics, and automation. Key takeaways included enhanced machine control, significant waste reduction through intelligent software and colour management, and improved sustainability via energy efficiency and near-shoring, ensuring agility and environmental responsibility in textile production.

FESPA 2025 gathers leading visionaries from across the speciality print industry in Berlin

FESPA Global Print Expo 2025, European Sign Expo and Personalisation Experience (6 – 9 May 2025, Messe Berlin, Germany) welcomed Visionaries from across the speciality print industry to shape the future of print, develop forward-thinking business strategies, and explore innovative ways to translate emerging industry trends into tangible growth opportunities.

Exploring Cutting-Edge Textile Printing Innovation with Adobe Print Engine 7

Adobe PDF Print Engine 7, launched at FESPA Global Print 2025, significantly advances textile printing. Debbie McKeegan shares how it automates non-white substrate management and RGB colour handling, expands colour gamuts with in-RIP multicolour transparency blending, and streamlines workflows for efficiency and sustainability. This update boosts customisation, reduces waste, and positions businesses at the forefront of digital print innovation.

FESPA Global Print Expo 2025 - Overall Highlights

FESPA Global Print Expo, Europe's leading print and signage exhibition returned to Messe Berlin from 6 - 9 May 2025.