Zünd releases Cut Center 3.0 software suite

Zünd has added new functionality to its Cut Center production planning and job management software.

Zünd is introducing Version 3.0 of its comprehensive Zünd Cut Center – ZCC software suite, which is designed to offer additional and enhanced registration methods for even greater productivity, as well as an added, browser-based dashboard for remote access to all performance and production data.

The company has expanded its suite with new functionalities and another boost in performance and user-friendly operation. The new release includes a variety of intelligent workflow options. Additional registration methods are said to generate significant increases in overall productivity.

Version 3.0 now includes refined algorithms for capturing only those register marks essential for accurately determining position, skew and distortion. Consequently, the ICC camera targets only critical marks for capture, translating into productivity gains.

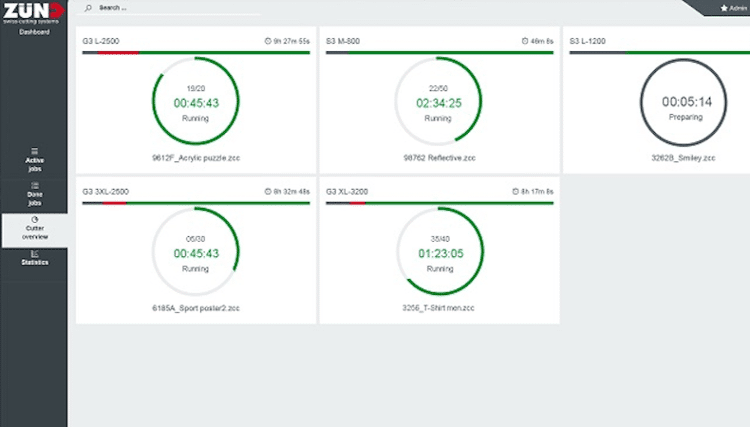

Dashboard is another highlight of the latest version of Zünd Cut Center. This new browser-based function visualises performance and productivity data of the Zünd cutters operating on the production floor.

Dashboard gives management and production staff easy, round-the-clock remote access to all relevant production data. Real-time job status can be viewed anytime, anywhere. Visualised statistics provide a clear, instantaneous overview of Zünd cutter productivity for user-definable time periods.

Quality and productvity

“Organisation and clarity are the be-all and end-all of smart production planning. That is exactly what Zünd's proven Cut Queue offers, with a tool palette that facilitates production planning and job management,” the manufacturer explains.

Cut Queue estimates production times and facilitates setup by visualising job contours. Many settings, such as overcut compensation and offsets for objects and cut paths, can either be handled automatically through hot folders or manually, at any time, via Cut Editor.

Hot folders automatically generate production-ready files from commonly used layout and CAD programs. This accelerates file prep and eliminates manual steps in job setup.

At the same time, the software also automatically optimises cut data for the shortest possible processing time by determining the optimal cut direction, cut sequence and cut path, closing open contours, smoothing curves, etc.

Cut Editor also provides such useful functions as crease-counter generation for high-quality creasing, powerful nesting features for maximum material yield, and a variety of routing features.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

How to grow your business with white ink applications

Opaque white ink is revolutionising signage, vehicle graphics, wallcoverings, short-run and wood packaging, and window blinds by enhancing vibrancy and clarity. This enables printers to offer high-demand, standout products, boosting profit margins. HP Latex white ink applications and their large format printing solutions will be showcased at FESPA 2025 in Berlin.