Zünd now cuts both ways, knife and laser

In a move that is sure to shake up the digital textile area, Zünd has introduced the LM 100W Laser Module, to cut and seal polyester fabrics in one efficient process.

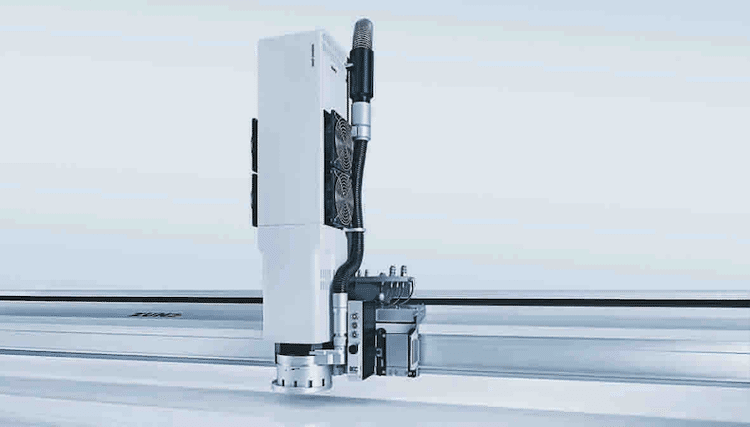

Because of the modular head system employed on Swiss-made Zünd cutting tables, users can switch between many cutting modes plus routing, and now laser cutting and sealing. This addition further amplifies the versatility of Zünd's modular, wide-format cutting systems.

“Textiles offer lightness, versatility, excellent colour rendition and handling for soft signage, theatrical backdrops or back-lit applications,” comments a representative from the company.

“Edge-fraying has sometimes been a problem with solutions such as ‘hot knives’ and seam-sewing offering a partial remedy. Now with Zünd’s new LM 100W Laser Module, textile printers can cut and seal edges all in one go.”

Zünd itself claims that soft signage offers tremendous potential in the vast and diverse world of visual communication media. Polyester fabrics are beginning to conquer applications previously ruled by paper and PVC substrates.

To facilitate cutting this material, Zünd has developed the LM 100W laser module, that is designed to cut polyester textiles and simultaneously seal the edges.

The LM 100W automates what has long been a separate, manual operation and thereby also eliminates the need for seaming. The LM 100W also delivers impeccable cut quality repeatability because laser cutting is a touch-free process and no hold-down is required during processing.

In minutes, one operator can convert a Zünd cutter to a full-blown laser-cutting system in a few simple steps. Once the laser job is completed, it is just as easy to reconfigure the cutter with modules for knife-cutting, passé partout or routing.

The Zünd laser module is equipped with an air-cooled CO2 100W laser with a processing speed of 44m/144 ft per min. As a Class one laser, it requires no special safety gear such as protective glasses. The laser module is fully enclosed, which provides reliable protection for the operator.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

How to grow your business with white ink applications

Opaque white ink is revolutionising signage, vehicle graphics, wallcoverings, short-run and wood packaging, and window blinds by enhancing vibrancy and clarity. This enables printers to offer high-demand, standout products, boosting profit margins. HP Latex white ink applications and their large format printing solutions will be showcased at FESPA 2025 in Berlin.