RMC Digital chooses Zünd to remove bottleneck

A second Zünd digital cutting table has been installed at RMC Digital Print, after the signage and exhibitions graphics specialist encountered a bottleneck in its workflow.

The Hull business installed a Durst printer in January 2017, doubling its flatbed printing capacity, and immediately found it required additional cutting capabilities to honour contracts and keep the print-room running 24/7. Its finishing department already ran a Zünd G3 3XL1600 and decided to invest in a second Zünd machine, a Zünd G3 XL3200.

"We needed to act fast to deal with the bottleneck created by the new flatbed printer," explains RMC Digital Print operations director Nicole Spencer. "Zünd provided a really quick turnaround – about six weeks from ordering the G3 to its installation."

In addition to the potential of a faster installation and an easier pre-press workflow offered by choosing a second Zünd, RMC Digital wanted to replicate the reliability and precision demonstrated by its first Zünd machine.

"Our existing Zünd runs day and night so we knew reliability wouldn't be an issue if we bought another Zünd," says Nicole Spencer. "It also cuts very precisely: when cutting hoarding or back walls for interiors, for example, being half a millimetre out can make a big difference."

The Zünd G3 XL3200 can handle Dibond and ACM hoarding quickly thanks to its 1Kw Router module, while RMC Digital Print also upgraded its creasing tool to fold foam board or card material in on itself – a niche job for one of the company's customers.

"Our customers want fast turnarounds and often change deadlines so we have to move work around on our production schedule," says Nicole Spencer. "We have to react quickly to changes in demand so having the second Zünd allows us to pre-press the job just once and we know it will be finished accurately."

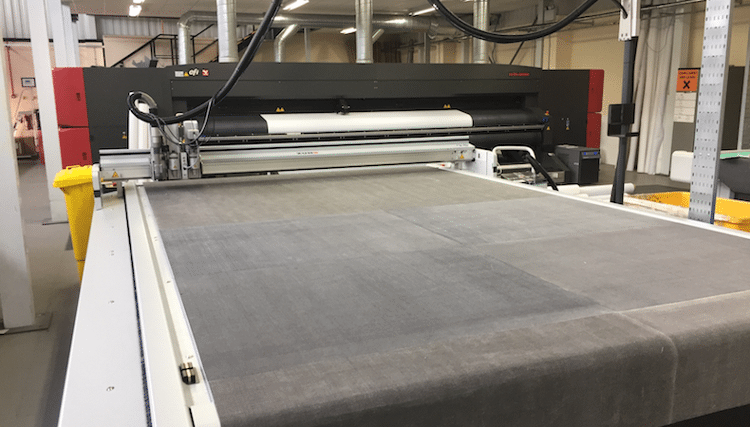

RMC Digital Print chose the Zünd G3 XL3200, a narrower but longer model than its first cutting table, which also has a conveyor to feed roll materials. The G3 can be tailored to specific cutting needs easily thanks to its modular construction and material handling options, making it a future-proofed cutting system ideal for a wide range of businesses across numerous industries. Its Swiss design exceeds safety standards and offers the highest automation capabilities, increasing output and minimising human error.

"The combination of Swiss manufacturing and a UK-based engineering team enabled Zünd UK to very quickly respond to RMC Digital Print's requirement for a reliable machine capable of the most accurate work," comments Zünd UK managing director Stuart Cole.

"The Zünd G3 is simply designed and built for 24/7, precise operation for demanding customers, so we expect the business to significantly increase its output."

In May 2017, Zünd Plotting Systems (UK) Ltd became a subsidiary of Zünd Systemtechnik AG, a family business based in Switzerland, making the St Albans-based company an integral part of the manufacturer offering a full and complete service to its customers in the UK and Ireland.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

Personalisation: From mass production to print-on-demand

Technological advancements are driving the growing trend of personalisation, fueled by consumer demand for unique products. From packaging campaigns like Share-a-Coke to customised apparel by Nike and Adidas, and AI-powered tools, the shift from mass production to print-on-demand is evident. The SmartHub Conference at the Personalisation Experience from 6 - 8 May will explore these opportunities and challenges for businesses.