OneVision launches new Wide Format Automation Suite

New from OneVision Software is the Wide Format Automation Suite which incorporates functions such as nesting, tiling and paneling, together with cut line management.

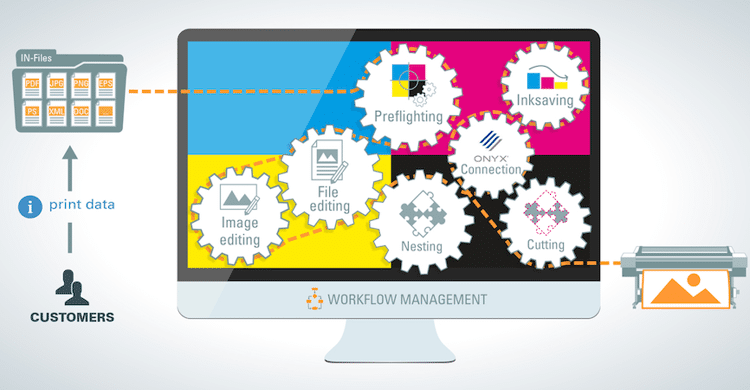

Automation Suite incorporates a flexible workflow management system, a comprehensive prepress package, innovative technologies such as nesting, tiling and paneling, as well as a direct interface between the software and the print press.

Workflows and assembly lines can be created digitally with an easy-to-use drag and drop editor – with changes possible at any time. The individual production steps are also automated by introducing major new functionalities to the workflow management system.

The first stage of the process involves basic optimisation and colour input calibration. This involves checking the print data quality of the incoming print jobs for possible errors using the ‘Preflight’ module. These errors are subsequently corrected to ensure smooth, error-free printing.

Depending on the job type, a variety of complex steps, including the generation of registration marks and barcodes, can also take place at the start of the process. Following data optimisation, transparencies are flattened to speed up the print process and avoid colour errors.

Finally, the normalisation module adapts all print data for consistency with the print environment, after which nothing more is required to enable smooth and error-free processing of print PDFs.

OneVision's Wide Format Automation Suite features an interplay between printing press and software

In order to minimise waste and to reduce surplus as far as possible, the Nesting Module can intelligently arrange print jobs from multiple customers in different shapes on a single sheet or roll.

The combined artworks result in a ganged output that optimises the use of the substrate, reducing the amount of waste while saving costs and improving the environmental sustainability of the production process.

The integrated Cut Line Manager accepts all cut line types and names and can automatically correct any damaged or incomplete cut lines. Missing bleed, varnish or white masks can easily be created with a fully automated process. Tiling and Paneling enables oversize formats to be divided into multiple, smaller files for easy printing.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

How to grow your business with white ink applications

Opaque white ink is revolutionising signage, vehicle graphics, wallcoverings, short-run and wood packaging, and window blinds by enhancing vibrancy and clarity. This enables printers to offer high-demand, standout products, boosting profit margins. HP Latex white ink applications and their large format printing solutions will be showcased at FESPA 2025 in Berlin.