Heidelberg introduces new rotary die-cutter

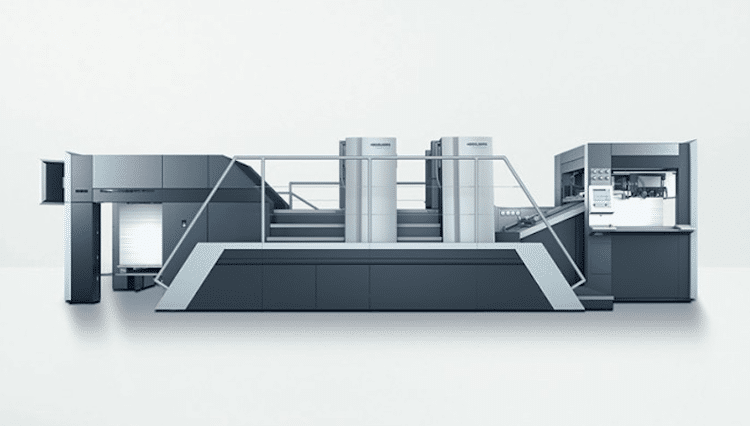

Heidelberg has launched its Speedmaster XL 106-DD rotary die-cutter for the in-mould label (IML) market.

The in-mould label market is continuously growing globally at around 4.3% (Awa Global Inmould Study 2017), and more than two thirds of the worldwide production is required for food packaging. Heidelberger is now offering an enhanced rotary die-cutter based on the XL technology, in addition to food-safe, highly efficient print production.

The Speedmaster XL 106-DD rotary die-cutter unites two key production steps in a single machine. The first unit places the injection hole in the label for the subsequent production process by means of a die on a magnetic cylinder with maximum precision. Up to now, this was a separate step that consequently extended the production time of the respective job.

The cut out material is safely and reliably removed by means of an extraction system. The second unit of the XL 106-DD subsequently cuts out the contour of the label from the sheet.

This combination of the two production steps in a single pass means a doubling of the die-cutting throughput, while makeready times and costs for die cutting tools can be reduced to half.

The XL 106-DD can process foils and papers at up to 10,000sph, which Heidelberg says is double the speed of a flatbed die-cutter, and takes materials ranging in thickness from between 0.05mm and 0.3mm.

Apart from in-mould labels, the XL 106-DD can also cut plastic or paper packaging elements, such as POS items which, due to their design, need a ‘window’ or hole for mounting in the shelf or for attaching to the product.

“A lot of customers are asking for this solution, who already have flatbed die-cutters but want the possibility to do hole punching and now we have the solution that they can completely change to rotary die-cutting,” commented Heidelberg product manager Philipp Doley to Printweek.

“On a flatbed die-cutter the cutting process for the sheet has to stop completely and speed up 100% afterwards, so you always have a hard stop and a hard run. On rotary, the sheet is always moving."

“The market is changing so if you have the possibility to cut and blend holes you can also speak about different kinds of holes, not only small injections but also the possibility to cut a window and extract the window in the label. So maybe this creates a new kind of product,” Doyle concluded.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

How to grow your business with white ink applications

Opaque white ink is revolutionising signage, vehicle graphics, wallcoverings, short-run and wood packaging, and window blinds by enhancing vibrancy and clarity. This enables printers to offer high-demand, standout products, boosting profit margins. HP Latex white ink applications and their large format printing solutions will be showcased at FESPA 2025 in Berlin.