Durst helps RPS grow new markets

A calculated risk with a near-£2million investment has paid off well for fast-growing Retail Print Solutions (RPS) since the acquisition of two Durst wide format printing systems.

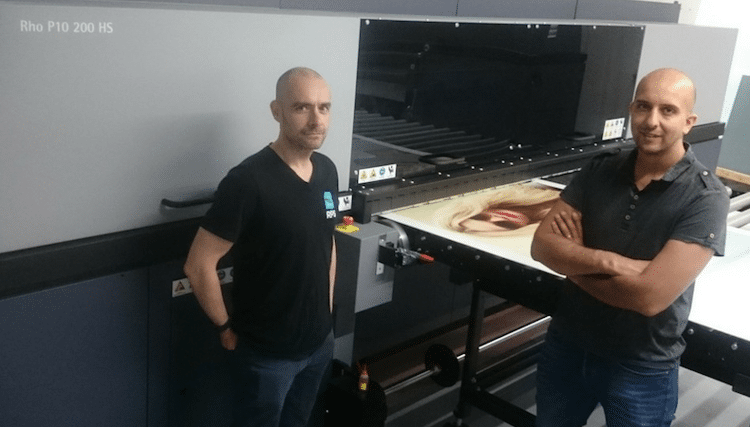

RPS, a UK-based full-service advertising and display specialist, anticipates reaching a £15 million turnover target in five years’ time, thanks to the investment in a Durst Rho 312 and a Durst P10 200 HS.

“Before we had the Durst pinters, we were turning away up to 50% of work requests because we just didn’t have the capacity, even though we were working double-day shifts," commented RPS managing director Kevin Boyle.

“With building works and other purchases, we invested a total of £2million. It was a calculated risk for a company of our size, but we’ve never looked back and now the orders are starting to flood in, we don’t have to turn them away!"

“The ability to print at such a high speed and achieve such great quality is fantastic for our business. These days, it’s essential to be able to turn round work incredibly quickly, and the Durst sysems really help to make that happen, for example, we are printing 1mx3.2m hoardings in a minute. And the service we get now is awesome,” Boyle added.

Point of Sale work currently accounts for around 90-95% of RPS’s turnover, but that is likely to go down to around 60% as the company expands into many other areas, such as exhibition work signage, retail displays and fabric backlit graphics. RPS customers are also increasingly demanding white ink solutions, which the Durst machines also provide.

RPS works in sectors as diverse as airports, retail and healthcare and one of its latest contract wins since the installation of the Durst printers has involved the production of graphics for an international vacuum cleaner company, which vetted RPS for print quality. That deal is likely to be worth in the region of £1million a year.

Durst UK managing director Peter Bray concluded: “We are delighted that our market-leading systems have had such a dramatic impact on RPS’ business. These Durst Rho 312 and P10 200 HS systems are providing the level of productivity it requires in is demanding production markets, and at an affordable price.”

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

How to grow your business with white ink applications

Opaque white ink is revolutionising signage, vehicle graphics, wallcoverings, short-run and wood packaging, and window blinds by enhancing vibrancy and clarity. This enables printers to offer high-demand, standout products, boosting profit margins. HP Latex white ink applications and their large format printing solutions will be showcased at FESPA 2025 in Berlin.