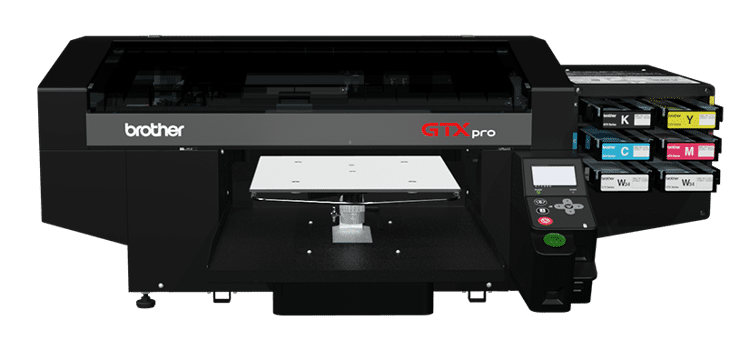

Brother releases GTXpro, the latest direct to garment printer

Brother At Your Side has launched the Brother GTXpro, their latest direct to garment printer which is currently available at their certified dealers.

Brother experienced success after launching the mass production machine GTXpro BULK a few months ago. The GTXpro provides the benefits of an operator friendly high-end direct-to-garment printer accompanied with leading technology from Brother.

GTXpro Features:

Newly Designed Industrial White Print Head

- Newly developed white print head technology with inside ink circulation, which results in using less white ink for cleaning.

High-Speed Print Mode

- The new design of the white print head features more nozzles compared to previous

models. This addition results in a 10% faster printing with special “fast mode” print settings.

Optimized Maintenance Process:

- Automatic cleaning processes significantly increases productivity.

Environmentally friendly

- OekoTex Passport and GOTS 5.0 certified Innobella Textile Inks

Operator friendly

- Installation and training by an authorized Brother DTG technician

- Additional Print Height Sensor: The new sensor technology detects if the platen is too low in order to reduce ink mist and ensures high print quality.

- Print Reservation Function for higher productivity

Flexibility

- Easy printing on a wide variety of textiles such as trousers, shoes, caps and much more.

- Printing on various materials is possible, from cotton to silk or polyester - all featuring the same ink.

- Compact industrial design and size suitable for all kind of production environment.

- Easy to move and add to any production – for a flexible process modulation of your production.

- All additional products from the GTX can be used with the GTXpro.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

Personalisation: From mass production to print-on-demand

Technological advancements are driving the growing trend of personalisation, fueled by consumer demand for unique products. From packaging campaigns like Share-a-Coke to customised apparel by Nike and Adidas, and AI-powered tools, the shift from mass production to print-on-demand is evident. The SmartHub Conference at the Personalisation Experience from 6 - 8 May will explore these opportunities and challenges for businesses.