Bobst launches M8

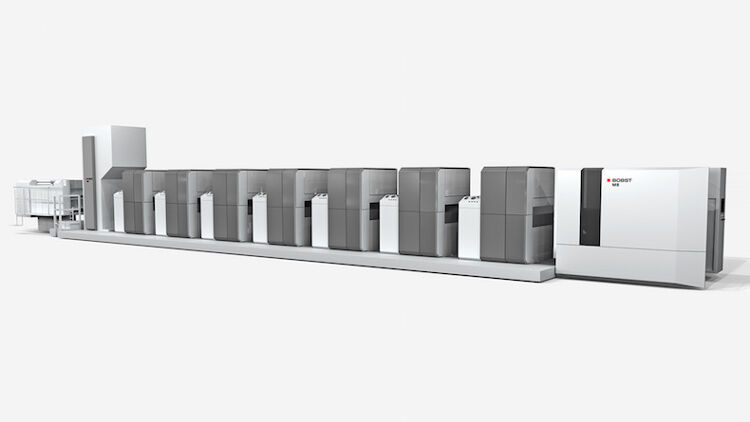

Bobst has introduced an upgraded flexo press, the M8 flexible packaging line, targeted at label converters looking to diversify into flexible packaging.

The new M8 is intended as an upgrade on the M5 and M6 flexo presses, with improvements in speed and wider web widths, along with the ability to take materials of higher grammage.

It can print at speeds of up to 400m/min, 150m/min faster than the M6, and has a web width of up to 1.1m. It prints on a variety of substrates, including paper, foil, lamitubes and film, handling substrates of up to 600gsm, double the highest grammage of the M6.

The machine has fully automated setup utilising Bobst’s Digital Flexo technology, which allows for complete digital control of the press and camera-monitored closed loop print operations that enable fully automated pre-register.

"Most printing companies today know they need to diversify in order to grow or even maintain revenue streams, and many label printers have been adding equipment to produce short run customized packaging to complement their revenue," commented Bobst Firenze managing director Matteo Cardinotti.

"The new Bobst M8 press is uniquely suited to forward-thinking label printing companies that want to move into the flexible packaging market in a way that exceeds contingency needs to allow strong and sustainable growth in this sector."

The press prints with UV, water- or solvent-based inks on a wide range of substrates, including plastic and aluminium filmic materials, laminated tubes and paper in a roll-to-roll configuration, while a special version converts cartonboard up to 600gsm.

Alongside digital control and total colour consistency, Bobst says the M8 delivers automatic on-the-fly job changeover sequences with up to 95% press uptime.

These features enable the press to operate profitably with all run lengths, including just-in-time orders. Also, the spectrum of substrates handled by the press includes all types used in packaging reel-to-reel printing: film, aluminum foil, lamitubes and paper.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

How to grow your business with white ink applications

Opaque white ink is revolutionising signage, vehicle graphics, wallcoverings, short-run and wood packaging, and window blinds by enhancing vibrancy and clarity. This enables printers to offer high-demand, standout products, boosting profit margins. HP Latex white ink applications and their large format printing solutions will be showcased at FESPA 2025 in Berlin.