Testing the waters with textile print

Textile print has emerged as a popular expansion market in recent years, but how can print service providers ensure a smooth transition into this form of work? Rob Fletcher speaks with some of the leading kit manufacturers in this sector to find out more…

One of the most diversified markets in the industry, textile print offers a whole host of opportunities to print service providers (PSPs) looking to expand their business into new areas.

From t-shirts and dresses, to curtains and cushion covers, the market stretches far and wide across a number of industries. But for those looking to enter into this sector for the first time, knowing where to start is no easy task

What sort of technology do you need to purchase? How can you be sure that you are using the rights sort of consumables to achieve quality output? Should you be looking at extra training to ensure your staff are up to speed with the techniques and technologies for textile print?

FESPA.com gets up close and personal with some of the top technology brands in textile print to find out how PSPs can succeed in this creative market.

Affordable and effective technology

One of the most recognisable names both in textile print and in the industry as a whole is Epson. Heather Kendle, market development manager at Epson Europe, encourages PSPs to consider moving into textile print, saying the market offers huge opportunities.

“According to Smithers Pira, the global market for inkjet will grow 9.4 percent each yea to reach $109bn (£84.7m/€95.1m) by 2023,” Kendle said. “IT Strategies predicts just 0.5 percent growth for signage over the next five years, while the textile market is still growing at seven percent CAGR.

“Growth is being fuelled by access to affordable and effective technology, a widening choice of fabrics and interest in textile printing beyond fashion and traditional interior design applications.”

Epson has a wide range of this technology on offer to both newcomers and those already in the market looking to expand their presence. The Epson SureColor SC-F range includes two 64-inch models: the high-end SC-F9300 and the medium-to-high volume model SC-F7200. In terms of entry-level, Kendle said the 44-inch SC-F6200 is suitable for low and medium runs and could be an excellent starting machine for a PSP.

Kendle said: “The cost of entry is not high. A SureColor SC-F6200, costs about £5,000, plus a heat press if required. There is then an upgrade path within the SureColor SC-F range as well as beyond to the Monna Lisa industrial textile presses.”

Caption: Available for £5,000, Epson’s SC-F6200 is suitable for low and medium runs and could be a good starting machine for PSPs

With kit like this in place, Kendle said PSPs can produce customised workwear, sports team kits and décor, as well as soft signage and promotional products. But for those looking at additional work, then a foray into direct-to-garment (DTG) may be beneficial.

Epson’s SureColor SC-F2100 costs around £11,000 and the user could add a pre-treatment unit for £3,500 and also a heat press for additional costs. The SC-F2100 features Epson’s Garment Creator software to support demand printing of cotton-based products, while the machine also has additional fast print modes and improved ink circulation for quick start up.

Kendle added: “DTG technology can extend the opportunities into cotton-based materials, either for corporate, sports or personal events. PSPs and sign-makers that have an online facility will find it quick and easy to take on this type of work and to provide a bespoke, distinct and stand-out product and service.”

Varied choice of media and technology

Another brand synonymous with the global print sector is HP. The company has had a presence in the textile print sector for some time and last year used FESPA 2018 to roll out its new 3800 Jumbo roll product.

Billed as its first real jumbo roll solution for flexible sign and textile printing in one device, HP has reported high interest in the 3800 Jumbo and Javier Larraz, HP’s large-format production director, GSB EMEA, believes this is down to how the machine help users access new markets.

Larraz said: “Our customers are now able to expand their offering into new, high-value applications while also opening fresh creative ideas and concepts for sign and display.

With this, Larraz speaks about HP’s history in the textile print market and why it value this sector of the industry so highly, drawing on the flexibility of HP Latex technology.

He said: “We’ve been interested in décor and soft signage for a considerable time at HP and believe that in order to address this market, you need to have a varied choice in media alongside a technology that is suitable for indoor environments.

Caption: HP launched the 3800 Jumbo, its first real jumbo roll solution for flexible sign and textile printing in one device, at FESPA 2018

“Since we launched HP Latex technology, we have been able to offer all the health and environmental benefits as it’s a water-based ink rather than solvent based.

“With HP Latex we are now able to print on natural and man-made fibre textiles; we offer technology to the market in an easy and fast way with good durability and colour.”

Larraz added: “HP Latex is currently the only technology that does not need any other finishing equipment to print on textiles. We don’t need calendars or other heating devices to cure our inks.”

Expand your horizons with digital print technology

Elsewhere, Bert Benckhuysen, senior product manager EMEA at Mimaki, also backs PSPs to move into textile print, highlighting the amount of opportunities within the fashion sector in particular.

Benckhuysen said: “It’s estimated that only 3 - 4% of today’s worldwide textile production is printed digitally, with the rest being printed using conventional analogue techniques. This demonstrates a great opportunity for PSPs to expand with digital textile print technology.

“There’s definitely a growing demand for shorter run, faster delivery and more customised or personalised production of textiles. For example, fast fashion requires quick production schedules at a low price.”

Benckhuysen builds on this, also speaking about the growth potential for PSPs in other areas of textile print: “We also see growth in demand for textiles in other sectors, such as soft signage and home décor. With interior décor, there’s an increasing demand for customised home textiles, such as curtains or cushions.

“Digital textile print technology is the key to facilitating these demands and unlocking these opportunities.”

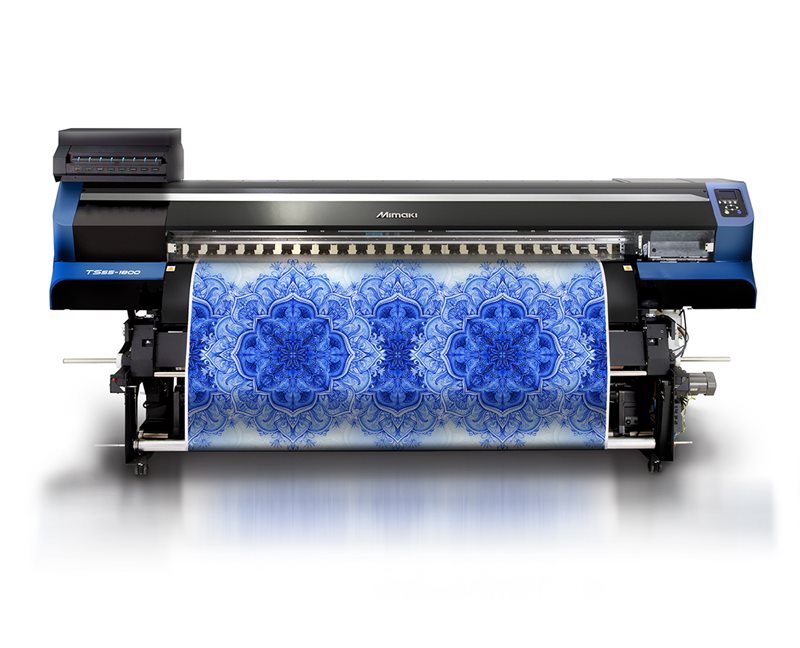

Leading on from this, Benckhuysen draws attention to some of the latest kit from Mimaki, namely the new Mimaki TS55-1800 and Tiger-1800B MkII.

First, the TS55-1800 is a dye-sublimation transfer printer that, Benckhuysen said brings high-end features to the entry and mid-level market. These include high-speed one-pass printing at a high-resolution and high ink-density; unattended printing with the new Mini Jumbo Roll unit and a set of Mimaki core technologies for continuous operation.

Caption: The TS55-1800 is Mimaki’s latest dye-sublimation transfer printer, offering users unattended printing with the new Mini Jumbo Roll unit

The Tiger-1800B MkII, an upgrade for the updated version of the Tiger-1800B, is a volume industrial textile production printer that offers speeds of up to 385sq m/hr. Users will benefit from high-quality print mode of 1200 dpi resolution as well as core Mimaki technologies such as the Mimaki Advanced Pass System to prevent banding, as well as Nozzle Check Unit and Nozzle Recovery System for continuous operation.

Benckhuysen added: “We are continuously developing and improving our products based on customer feedback, while also researching the market to deliver products and features that deliver differentiation and increased profitability.”

Offer something different to your clients

Roland DG is of a very similar mind-set, with Paul Willems, head of business development and product management at the manufacturer’s EMEA division, said textile print opens up a world of applications. With demand for work such as soft signage, exhibition graphics, sports and fashion apparel, corporate wear and interior decoration on the rise, he called on sign-makers and PSPs should take advantage.

Caption: Roland DG will roll out its new VersaSTUDIO BT-12 direct-to-garment printer in April

Williams said: “For PSPs working in the competitive sign market, anything which enables them to differentiate themselves and to offer something different to their clients is advantageous. And, of course, offering textile print services will enable PSPs to pursue new business, potentially allowing them to grow in previously unexplored markets.

Williams leads on from this to outline some of the solutions that are on offer from Roland DG, including the new multi-function Texart RT-640M. The latest addition to the Texart dye-sublimation range, the machine offers direct-to-textile and indirect sublimation in a single device.

William said: “The RT-640M offers textile print suppliers a truly versatile digital dye-sublimation solution to produce apparel, soft signage and non-textile applications. Plus, printing direct-to-textile enables users to easily produce double-sided flags, banners and backdrops.”

Roland DG will soon launch its new VersaSTUDIO BT-12, a compact direct-to-garment printer that prints full colour graphics onto cotton-based items such as t-shirts, tote bags and textile interior decoration products. Available from April, the machine can print sharp, colourful photos, logos and text directly onto a wide variety of products.

William added: “Roland DG is committed to innovation and is constantly looking at ways in which our technology can help give our users the best competitive advantage; everything we do is inspired by our customers.”

This closing statement sums up the situation in the textile print market; much is going on in terms of development and there is a lot to get excited about when it comes to taking on new work. By planning your move properly and investing in the right type of kit, you can make a successful transition into textiles.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

How to grow your business with white ink applications

Opaque white ink is revolutionising signage, vehicle graphics, wallcoverings, short-run and wood packaging, and window blinds by enhancing vibrancy and clarity. This enables printers to offer high-demand, standout products, boosting profit margins. HP Latex white ink applications and their large format printing solutions will be showcased at FESPA 2025 in Berlin.