Printing plates progress

As digital printing keeps up its steady march across the graphics landscape, it’s easy to forget about progress in conventional printing, writes Laurel Brunner.

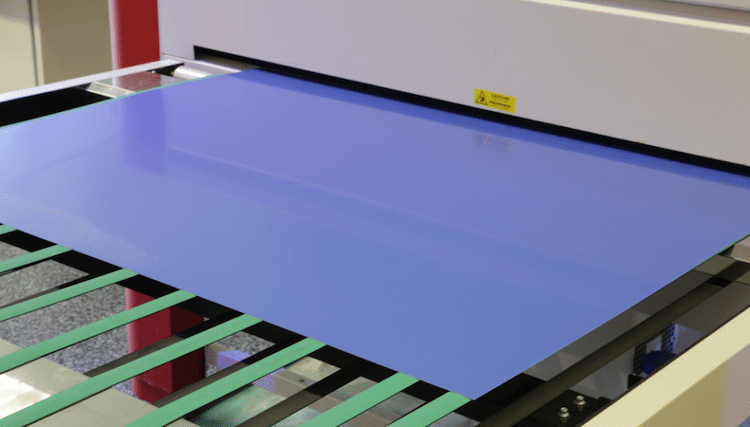

In addition to improvements in makeready times and energy efficiency on press, great strides have been made with consumables, especially printing plate technologies. Most attention gets paid to processless plates such as Agfa’s Azura, Fujifilm’s ProT and Kodak Sonora. But these are not the only technologies to have helped drive down environmental impacts.

The bulk of the printing industry still uses processed plates, and here too technology advances have been considerable. Ten years ago thermal plates had to be handled under special lighting and were good for around 150,000 to 200,000 impressions.

They generally had to be baked for longer runs, but baked plates would last for well over a million impressions. Imaging performance was around 200 lpi with resolution at 1-99% and platesetter imaging times were far slower than today’s rate of 70 plates per hour for 8-up plates.

Today thermal plates are daylight safe and platesetters are available that can output 4,000 dpi for high quality applications. And the aluminium used for printing plates can be recycled, generating revenue for printers, saving resources and primary raw materials extraction.

The story keeps improving despite declines in conventional print volumes and the advance of processless plates and digital printing methods. Agfa for instance has introduced the Arkana smart plate processing technology, which only uses small amounts of chemistry to clean the plates, and has a bath life of 15,000m2. The unit can be rinsed out with tap water, so waste and maintenance overheads are reduced.

When processing the Agfa Energy Elite Eco plate, for instance, waste is reduced by 50% compared to other processors and there is no hazardous waste water to dispose of. The secret to these advances and others like them is in the coating technology.

The Energy Elite Eco thermal plate has a dual coating solid enough to print long runs, yet sensitive enough for high quality imaging at 340 lpi and a 1-99% dot resolution. The plate requires no pre- or post-baking and is good for commercial and packaging runs of up to 600,000.

For UV applications it’s good for 150,000 impressions. And the plate has reduced dampening requirements. Across the industry technological develops like this are all helping to cut the environmental impact of print, making both the medium and the business more sustainable.

Source: This article was produced by the Verdigris project, an industry initiative intended to raise awareness of print’s positive environmental impact. This commentary helps printing companies keep up to date with environmental standards, and how environmentally friendly business management can help improve their bottom lines. Verdigris is supported by the following companies: Agfa Graphics, Spindrift.click, EFI, FESPA, HP, Kodak, Kornit Digital, Ricoh, Splash PR, Unity Publishing and Xeikon.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

How to grow your business with white ink applications

Opaque white ink is revolutionising signage, vehicle graphics, wallcoverings, short-run and wood packaging, and window blinds by enhancing vibrancy and clarity. This enables printers to offer high-demand, standout products, boosting profit margins. HP Latex white ink applications and their large format printing solutions will be showcased at FESPA 2025 in Berlin.