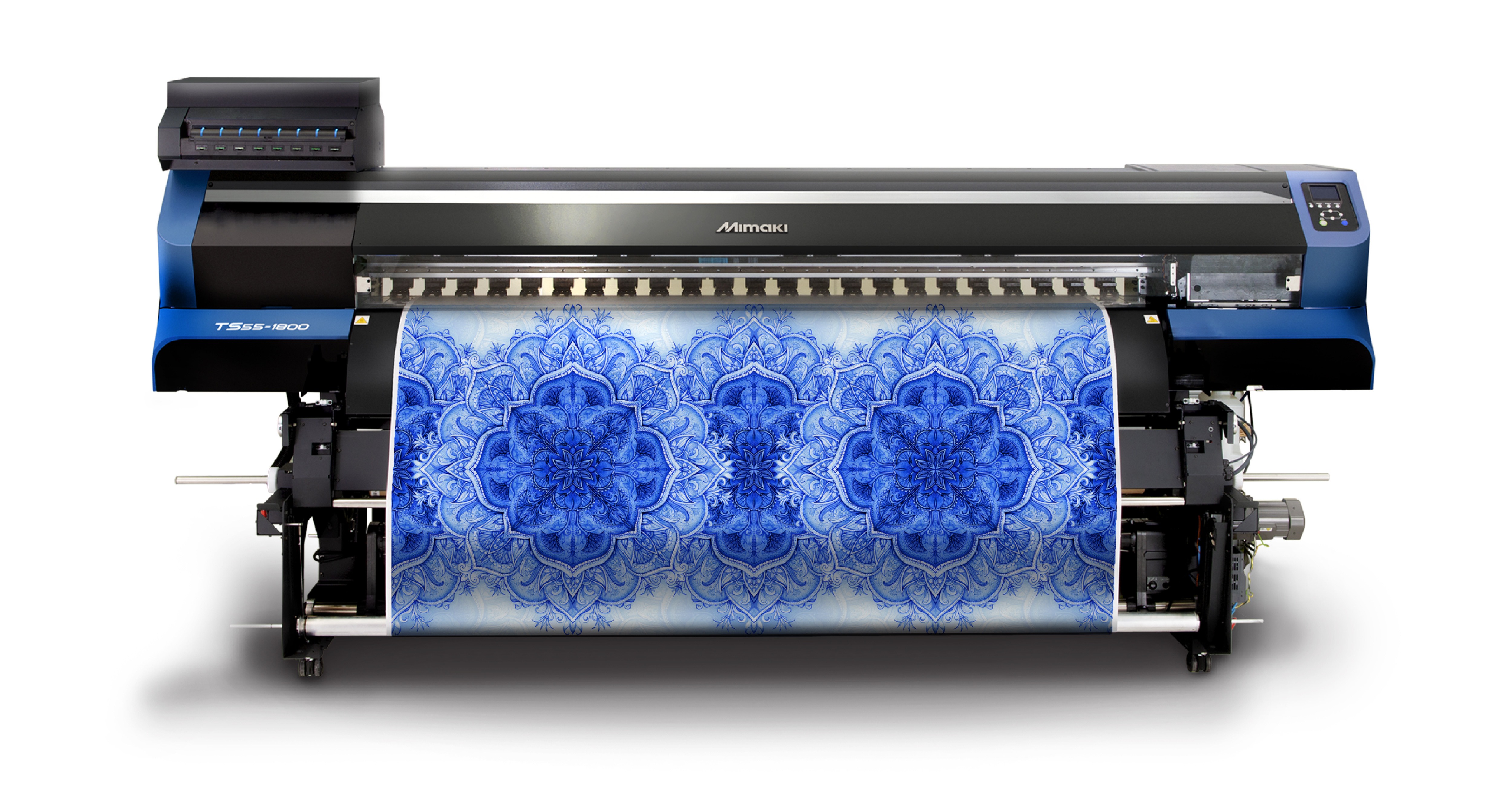

Mimaki targets textiles with TS55-1800

.jpg?width=750)

Rob Fletcher speaks to Mimaki about the TS55-1800, a breakthrough digital textile printer that will surely cause a stir in the market.

Mimaki has expanded its portfolio of digital print solutions with the launch of the new TS55-1800, a machine designed to address growing demand for work in the printed textiles market.

The digital heat transfer sublimation printer pledges to bring “high-end features” to entry-level and mid-level markets. Key features include one-pass printing at a high-resolution and ink-density, unattended printing with the new Mini Jumbo Roll, and Mimaki’s Nozzle Check and Recovery System for continuous operation.

Mimaki said the TS55-1800 can print at speeds of up to 140sq m/hr and at a resolution of 480 x 600dpi. In addition, the manufacturer said that the Mimaki Advanced Pass Systems will boost the quality of two-pass prints by eliminating banding.

Speaking to FESPA.com about the new printer, Bert Benckhuysen, senior product manager at Mimaki, said the main reasons behind developing the product were to deliver a solution that is of “higher quality, more productive, and more price-competitive” that offers users “higher profitability”.

“We believe the TS55-1800 ticks all these boxes; it’s a robust, productive dye sublimation printer that produces high quality results and offers our customers an increased price-performance ratio,” Benckhuysen said.

“With the new (r)evolutionary Mimaki TS55-1800, we are also bringing features that are normally only found in high-end textile printers to the entry and mid-level market.

“For example, we’ve added high-speed one-pass and two-pass printing at a high resolution and with high ink density. This means that while our competition has to reduce speed to maintain strong colours, we can deliver with one-pass at 140sq m/hr.

“Furthermore, we introduce our new Mini Jumbo Roll unit, which will enable our customers to continuously print up to 2,500 linear meters of heat transfer paper with this printer, saving on paper running cost. Additionally, to even go lower in running costs, the TS55 can be equipped with a 10kg ink supply system.”

In terms of the type of companies that should look to invest in the new machine, Benckhuysen said Mimaki designed the product with all customers in mind and suggested that the TS55-1800 would fit into all types of textile print business.

“Textile production companies, no matter how big or small, can definitely benefit from this printer,” he said. “We want to help them realise higher profit and grow their business with this amazing, market-stirring printer.”

Benckhuysen added in a statement: “The TS55-1800 is a breakthrough digital textile printer, that will surely cause a stir in the market. It has been designed from the ground up to deliver high quality, industry-leading productivity and an operational cost that will be hard to beat.”

The machine launches this month.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

How to grow your business with white ink applications

Opaque white ink is revolutionising signage, vehicle graphics, wallcoverings, short-run and wood packaging, and window blinds by enhancing vibrancy and clarity. This enables printers to offer high-demand, standout products, boosting profit margins. HP Latex white ink applications and their large format printing solutions will be showcased at FESPA 2025 in Berlin.