Latin American printers reinvent themselves in the wake of COVID-19

.jpg?width=750)

James Gatica discovers how the printing industry in Latin America is coping and what printers are doing to help during COVID-19, from making masks and non-invasive assisted breathing equipment in Spain, Mexico and Argentina.

With the number of cases of COVID-19 now reaching nearly 2 million, this pandemic is affecting everyone around the world with entire countries being confined to their homes and economies reaching a stand still. These factors have led to numerous industries reinventing themselves and addressing this crisis as a business opportunity.

Spain is one of the countries that has been most affected by COVID-19. Getting materials for manufacturing masks has become an absolute priority. The Spanish Ministry of Industry, Trade and Tourism have created new job opportunities with various SMEs and start-ups to try and adapt their 3D printing activities to produce masks and non-invasive buconasal assisted breathing equipment.

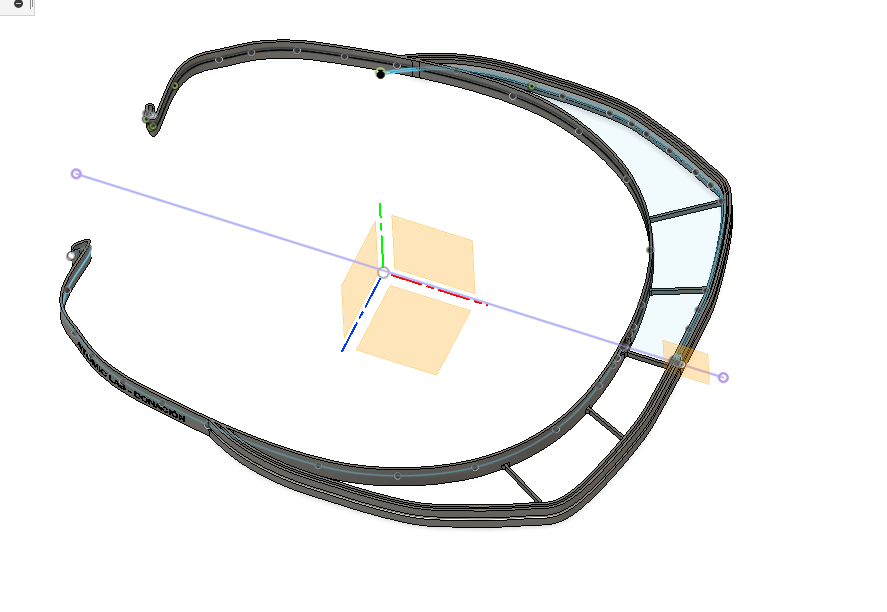

Spanish company, Intech3D focuses full time on the production of masks, visors, respirators and other materials that can be used to prevent the spread of coronavirus. The 3D printing and additive manufacturing company collaborates in the '3D Printing Covid-19 Task Force' initiative that provides fast, adaptable and scalable solutions to tackle the lack of medical resources in hospitals and medical centres.

Image courtesy of Intech3D.

Intech 3D comments: “Although everyone is doing their bit to help, collectively everyone helping will make a difference in this struggle by supporting our health workers, who are constantly working to help those affected with the coronavirus.”

Intech3D has 15 machines with different technologies with the ability to produce resources with any material. In addition, the machines can 3D scan any component or part that needs to be multiplied and can be produced quickly.

From a .stl file to Mexican hospitals

The versatility and practicality of 3D printing has led printers such as Czech company, Prusa to provide their mask designs before the COVID-19 crisis and now they are being offered to healthcare workers around the world.

Mask model design by Prusa.

Prusa commented: "When we started delivering the masks to doctors and those on the frontline, we had no idea of how rapidly this virus would spread around the world. Thank you to everyone who decided to join this cause.”

In Mexico, Jaime Trinidad of LT3DLab turned his hobby into something to help health workers and today he has become one of the leading “Humanitarian Printers” in Mexico. Trinidad already owned a Prusa i3 MK3S printer in his home. Using this printer, he began to manufacture 16 masks a day, after seeing the news about the shortage of medical supplies in Latin America. It was a wake-up call that he knew how to answer.

One of Jaime Trinidad's first impressions #ResistanceCovid.

"My first prototypes I used soft drink bottles, I showed them to my medical friends who immediately told me how many I needed to print. That's when I knew I had to get the materials and get to work," Trinidad tells Fespa.com.

In just one week, he rallied his community to join a crowdfunding campaign which far exceeded the initial goal. He increased the production of his at-home mask factory and added 3 Creality Ender 3 printers. With these printers he prints 10-12 masks on each printer each day. So far, Trinidad has delivered 360 masks to public hospitals in the Mexican capital and estimates a further 400 masks will be printed in the coming days. "I feel happy that I can help health workers they are always so grateful for donations and support.” says Jaime Trinidad.

LT3DLab production line in Mexico City.

The "Atomic Captain" to the rescue

Similarly, in Argentina Gino Tubaro is known for making 3D prostheses for amputee children and decided to collaborate in the production of sanitary supplies to support medical teams in Argentina. He worked with The Atomic Lab to create a design which is a half mask that protects the nose and mouth and has filters, so as not to obstruct breathing. "We have over 90,000 orders, all can be viewed and sorted by distance from limbs.earth.” says Gino,

The model designed by Atomic Lab is available for free.

The Atomic Lab offers every person who has a 3D printer in their home templates that are based on successful international designs for producing masks. Siemens Foundation will assist by removing the waste from the homes of each mask manufacturer, and for every 25 masks produced, it will deliver 1 kilo of extra filament free of charge. The protective acetate will be applied to it ensuring optimal hygiene conditions.

The masks produced will be mainly donated to health centres and facilities at risk of contagion in partnership with the Ministry of Health (Argentina).

Physician from Córdoba, Argentina received one of the masks printed by one of the volunteers.

"We invited the entire community and 3D printing enthusiasts from the City and Greater Buenos Aires to join as volunteers for this initiative to work as a team and help with this critical situation we are faced with today," added Gino Tubaro.

Pablo Aldrovandi, Project Manager of the Siemens Foundation said: "Today, more than ever the joint effort between the private sector, civil society organizations and government is key to responding to the problems that face today with COVID-19. We are all facing the same huge issue but working together we can all be part of the solution."

"I always thought that 3D printing revolutionized the print industry and it has now become a shining hero to battle against this crisis. If I was asked to print the nozzle of the fans tomorrow, I know I will be able to do it," says Jaime Trinidad from Mexico.

Digital printing offers a solution to address the COVID-19 crisis.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

Personalisation: From mass production to print-on-demand

Technological advancements are driving the growing trend of personalisation, fueled by consumer demand for unique products. From packaging campaigns like Share-a-Coke to customised apparel by Nike and Adidas, and AI-powered tools, the shift from mass production to print-on-demand is evident. The SmartHub Conference at the Personalisation Experience from 6 - 8 May will explore these opportunities and challenges for businesses.