Innovative examples of the unlimited potential of print

.jpg?width=750)

Every printer knows that you can create innovative products with print. But would you have ever thought printed products can help science to find sub-atomic particles? Or make a surround system speaker? Sonja Angerer shares 3 very unusual print applications that will surprise you.

Ever considered buying a surround system for your event or trade fair booth? You may have decided against it as not only are these systems expensive, but usually require numerous cables which can be dangerous in crowded environments. Not anymore.

Surround speakers, printed roll-to-roll

Caption: Printed speakers in the “T-RING” at TU Chemnitz create surprising jungle illusion. Image credit: Jacob Müller

Caption: Printed speakers in the “T-RING” at TU Chemnitz create surprising jungle illusion. Image credit: Jacob Müller

A group of scientists at the Institut für Print- und Medientechnik at TU Chemnitz (Institute for Print and Media at Chemnitz University of Technology) have been working on printed speakers for nearly a decade. In January 2021, they experienced a break through. It is now possible to print “T-Paper” roll-to-roll. “T-Paper” is the name the project leader Georg C. Schmidt gave this product. T-Paper is two layers of plain paper, each printed with conductive organic polymer for electrodes. Between the papers, another piezoelectric “active layer” starts to move, causing vibrations through the thin, laminated sheets. This results in a fairly loud and clear sound (Video).

In their latest experiments, the Chemnitz scientists connected seven segments creating a 4 meters long panel with 56 individual speakers which was then formed it into a “T-RING” circle. The speaker panel includes printed circuitry and is only about 150 grams in weight. 90% of the construction is just plain paper that can be printed in colour on both sides, as the electronics is securely laminated between the paper sheets (Video).

“This means that low-cost infotainment solutions are now feasible in museums, at trade fairs and in the advertising industry”, says project leader Georg C. Schmidt. He adds: “In public buildings, very homogeneous sound reinforcement is possible for long stretches such as corridors.”

Printer manufacturers hosts Fashion Week

Caption: Motty Reif, Entrepreneur and Executive Producer for Fashion Week Tel Aviv in front of Kornit Digital Logo, as the manufacturer will present this years edition of the fashion show. Image credit: Kornit Digital.

Caption: Motty Reif, Entrepreneur and Executive Producer for Fashion Week Tel Aviv in front of Kornit Digital Logo, as the manufacturer will present this years edition of the fashion show. Image credit: Kornit Digital.

In recent years, digital print production has become an essential tool for establishing new designs and best practices in the fashion industry. However, a printer manufacturer hosting a national Fashion week still seems unusual. Until now, as Fashion Week Tel Aviv 2021, 28th March – 1st April will be presented by Kornit Digital.

The opening gala will be hosted by supermodel Bar Rafaeli and Tel Aviv Fashion Week founder Motty Reif. Over 40 fashion designers have been invited to showcase their latest collections. Alongside design matters, the event’s core theme is “#wearyourcare” which highlights the collaboration of technology and fashion.

“A decade ago, I started Tel Aviv Fashion Week in order to promote our local talent internationally,” said Reif. “For the past 5 years, we’ve been a driving force behind inclusivity in fashion, and now we are tackling the industry’s most pressing issue of our time and joining forces with Kornit in order to make production more sustainable—start-up nation technology meets fashion, to change the world together.”

3D print helps to detect subatomic particles

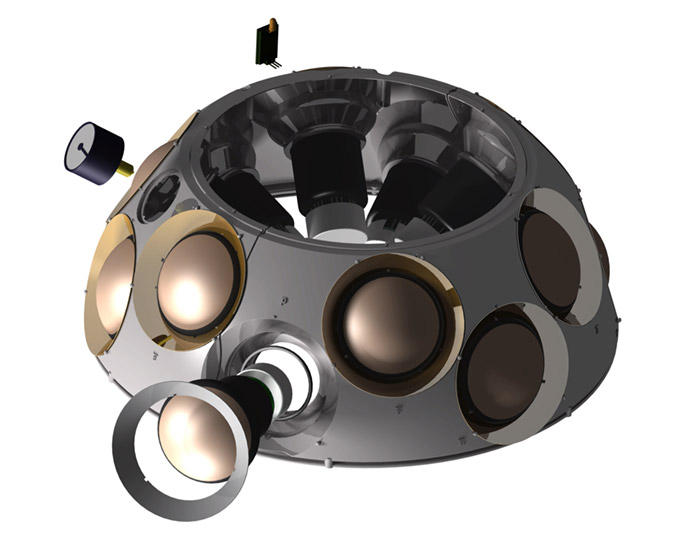

Caption: Rendering of the DOM half-spheres printed by Weerg with a Multi Jet Fusion 5210. Image credit: Weerg

Caption: Rendering of the DOM half-spheres printed by Weerg with a Multi Jet Fusion 5210. Image credit: Weerg

The acronym KM3NeT is not well known to many people outside a small scientific community. It is a project led by the Dutch National Insitute of Subatomic Physics (Nikhef), designed to detect the elusive Neutrino particle with the Cubic Kilometer Neutrino Telescope.

KM3NeT started in 2013 and is due to be completed in the late 2020s. During this time approximately 6.000 spheres with optical and other sensors will be installed deep in the Mediterranean Sea, off-coast France, Italy and Spain. The Digital optical Modules (DOMs) are about the size of a football, their exterior custom-made for the purpose.

After trying several suppliers over the years, Nikhef finally discovered Europe´s largest installed base of HP Multi Jet Fusion 5210 3D printing technology at Italian 3D Online printing Service Weerg.

Each half-sphere is 380 mm in diameter, which is the maximum size available with the HP printer. The spheres are printed with Nylon PA12, a very robust and rigid material, and finished with black paint at Weerg´s. The first trial batches were delivered about two years ago and finally installed at the station in the deep sea off Toulon. By spring 2021, the total number of DOMs will double, thanks to Weerg´s innovative 3D print offer. “From my experience, I can say that Weerg is the best 3D printing service in the world”, says Edward Berbee, a Nikhef leader.

Discover new markets in the most unlikely of places

While the above examples seem rather spectacular, and not lines of business most printers would work in, they are certainly inspiring. Print technology is very versatile, so it can be used in a wide variety of markets. Add this with the creativity of the people working in the industry, there are virtually no limits in what print can do…

Discover the latest in 3D printing, digital printing and garment printing at the Global Print Expo 2021, Europe's leading exhibition for screen and digital wide format print, textile printing and signage. Discover the latest products, network with like-minded individuals and explore new business opportunites. Register your interest here.

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

.png?width=550)

How to leverage Adobe PDF Print Engine for efficient, high-quality printing

We speak to Mike Scrutton Director of Print Technology & Strategy at Adobe at the FESPA Global Print Expo 2025 in Berlin about the Adobe PDF Print Engine for commericial print production.

The latest innovations in DTF printing

The Direct-to-Film (DTF) market is experiencing significant growth, with major printers now offering dedicated solutions. Beyond the traditional textile applications, there's a notable expansion into UV DTF technology, allowing for heat-free application to various objects. This evolution, alongside advancements from companies like Epson, Roland, Brother, and Ricoh, indicates DTF's continued diversification and increasing appeal for diverse printing needs.

.png?width=550)

Personalisation Experience 2025 - Overall Highlights

Personalisation Experience 2025 saw the meeting of global visionaries exploring the opportunities of smart manufacturing and personalisation in print through on-demand digital technologies.

.png?width=550)

How to streamline 5-meter textile printing with the Durst P5 500 Tex iSub

We speak to Christian Harder, VP of Sales at Durst at the FESPA Global Print Expo 2025 in Berlin.