Dyss bottles success for Print Leeds

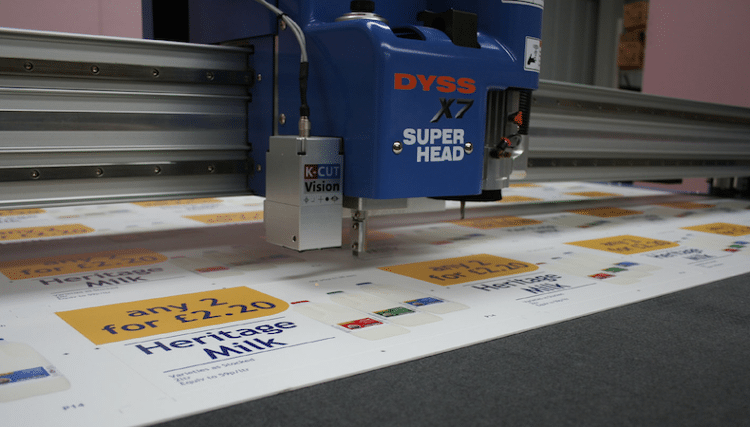

Wet-glue label, digital POS and litho UV plastics printer Print-Leeds has invested in a Dyss X7-1630C digital cutter.

As far as growth and investment goes, there are few print businesses currently spending at the level of Print Leeds. The rapidly evolving company has invested over £3.5m in the last four years with a projected spend of an additional £5m in the next 18 months.

In the last four years, the West Yorkshire business has undertaken a factory refurbishment and extension and also acquired a Heidelberg Speedmaster CX102 UV seven colour printer, and just recently a Dyss X7-1630C digital cutter from AG/CAD.

In the next 6 months, the company will skyrocket its investment plans with a move from the current 20,000sq/ft factory to a 32,000sq/ft facility and also install another Heidelberg Speedmaster XL106 seven colour printer.

With a factory move planned over the summer and the Heidelberg arriving just before Christmas, the management won’t get time to relax much during the seasonal holidays in 2017. Thankfully, as part of its investment strategy the 38 employee business purchased the Dyss X7-1630C to help lighten the load.

The company has specialist divisions with core competences in producing wet-glue labels, UV litho printed plastics, and digital printing that caters for the PoS market and the printing of beverage and food packaging.

As one of the most technically advanced printers in the UK, the business always has an eye on the latest technologies and the 3m by 1.6m Dyss-1630C digital cutter was purchased to replace a smaller, slower and aging cutter. Like the Heidelberg, the Dyss has been acquired to provide capacity, flexibility and added capability at Print Leeds.

Print Leeds managing director Rod Fisher said: “We bought the previous cutter to reduce our reliance on dies and subsequent costs. However, as the PoS and packaging work has grown, we’ve recognised the need for a machine much larger than the previous B2 format."

"We also needed a router cutting capability for the ever increasing diversity of tough materials we handle, something our previous machine couldn't offer. I reviewed the market and the Dyss immediately stood out above the competition for its build quality, capability and the price point."

The device can cut materials including polypropylene, PVC, foam-board, acrylic and vinyl. The additional Dyss X7 Superhead, which has an oscillating knife tool, can be used for high speed routing as well as creasing, kiss-cutting and several precise cutting operations.

"Having the ability to cut 3m printed boards and sheets on the Dyss has already made significant savings over its smaller predecessor. Moreover, we can cut a number of smaller jobs from a single sheet and this has reduced set-up times considerably, improving productivity by over 20%," added Fisher.

"Furthermore, the Dyss can cut jobs at least 30% faster than the previous machine. The Truepress was recently upgraded to a high speed model and, without the equally fast Dyss, we would have had a major bottleneck."

As well as streamlining production and improving productivity, the machine has reduced costs for the rapidly growing company. Cutting a higher volume of small components from large boards is generating a material saving, reducing waste and costs for the environmentally conscious employer, the company said.

Before investing in the Dyss machine, Print Leeds was outsourcing a percentage of its litho work that required cutting. The company said the machine has reduced its reliance on subcontractors by at least 20% and will save it more than £20,000 a year.

“As well as subbing out cutting of litho work, we used to get Perspex and acrylic jobs cut externally. This is because our previous cutter didn’t have a routing head. Jobs such as shop signage, placards and some PoS work had to be subbed out with a lead-time of around 2-3 days. Now, we can cut these materials in-house to reduce our reliance on external suppliers, eliminate the cost element and shave 2-3 days off the lead-times," concluded Fisher.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Industry Experts Explore the Evolution of Smart Manufacturing in the Textile Industry

A FESPA SmartHUB roundtable at Personalisation Experience 2025 discussed smart manufacturing's transformative impact on the textile industry. Experts highlighted the shift to on-demand customisation, driven by digital printing, data analytics, and automation. Key takeaways included enhanced machine control, significant waste reduction through intelligent software and colour management, and improved sustainability via energy efficiency and near-shoring, ensuring agility and environmental responsibility in textile production.

FESPA 2025 gathers leading visionaries from across the speciality print industry in Berlin

FESPA Global Print Expo 2025, European Sign Expo and Personalisation Experience (6 – 9 May 2025, Messe Berlin, Germany) welcomed Visionaries from across the speciality print industry to shape the future of print, develop forward-thinking business strategies, and explore innovative ways to translate emerging industry trends into tangible growth opportunities.

Exploring Cutting-Edge Textile Printing Innovation with Adobe Print Engine 7

Adobe PDF Print Engine 7, launched at FESPA Global Print 2025, significantly advances textile printing. Debbie McKeegan shares how it automates non-white substrate management and RGB colour handling, expands colour gamuts with in-RIP multicolour transparency blending, and streamlines workflows for efficiency and sustainability. This update boosts customisation, reduces waste, and positions businesses at the forefront of digital print innovation.

FESPA Global Print Expo 2025 - Overall Highlights

FESPA Global Print Expo, Europe's leading print and signage exhibition returned to Messe Berlin from 6 - 9 May 2025.