From Standfast & Barracks to Ricoh’s Customer Experience Centre

Graeme Richardson-Locke visits British fabric printer Standfast & Barracks and Ricoh’s customer experience centre in Telford to meet Jason Dale, Colour Champion CIP.

Over the last few weeks I have been a guest at a range of factories and events. This has reminded me of the vast number of talented professionals who work across every imaginable industry who use screen and digital printing technologies to create their products.

Accompanied by a handful of FESPA colleagues and FESPA’s Textile Ambassador, Debbie McKeegan we visited Standfast & Barracks, one of the leading British roll textile factories printing fabric for applications including upholstery and curtaining. Managing Director, Stephen Thomas and Design Director, Emma Douglas kindly gave us a tour of the factory. Standfast & Barracks are also an accomplished design house with 3 centuries of archives that they use to inspire their future collections.

It was fascinating looking at master swatch design books from the early 20th century and reading the comments about the news at the time. I have had some involvement in silk printing years ago, the scale of the factory wasn’t a complete surprise. But the variety of fabric processing equipment that is required to singe cotton seeds, remove weaving size and bleach cotton to even get close to being printable was.

Walking through the factory we saw their multicolour rotary and flatbed screen printing lines extending off into the distance, where spot colours including metallic, fluorescent and special textures still provide finishes that digital is incapable of. However, as a forward-thinking business their print armoury would not have been complete without a full compliment of reactive dye and pigment digital systems. Standfast & Barracks have gone to great lengths to ensure that the quality of the print created with these more contemporary methods meets the exacting standards that the markets demand. We saw the results of their wide-ranging tests that they conduct to ensure that the best pre-treatment chemistry is in place to achieve great colour across a broad spectrum of fabrics. I’m certain that Durst, whose print systems dominate their digital facility have benefited from engaging with the company and its wealth of experience.

.jpg?lang=en-GB)

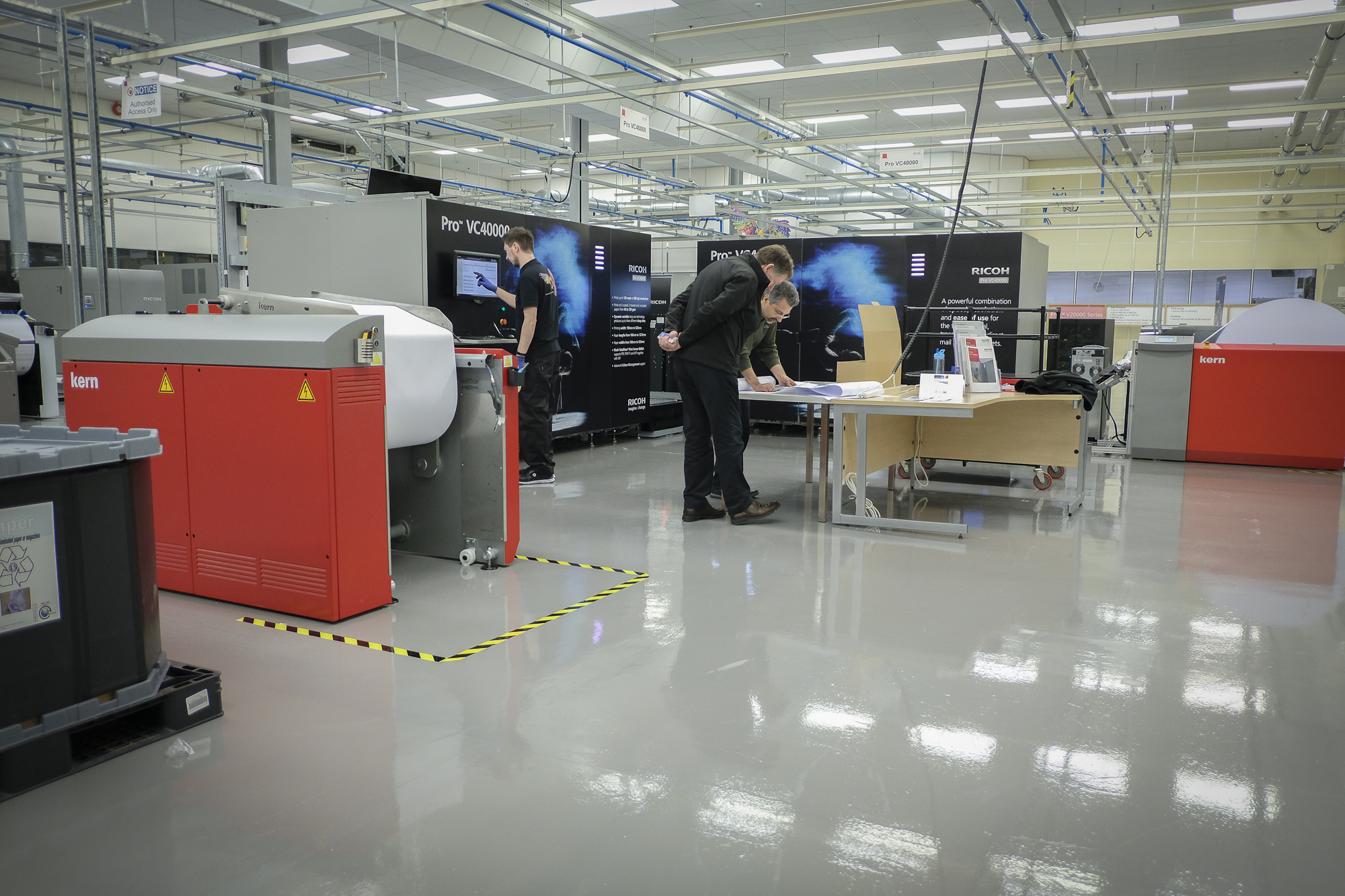

My next visit was with Paul Sherfield, the expert Colour Management consultant and FESPA’s Colour Ambassador. We visited Ricoh’s Customer Experience Centre in Telford to meet Jason Dale, Colour Champion CIP who supports the businesses’ colour management achievements and is responsible for their FOGRA certification and with Paul’s support, BPIF’s Colour Quality Scheme with the Elite certification.

Ricoh has a range of document print systems, from continuous feed single pass inkjet running at up to 150 metres per minute through to colour toner based small format printers. All were impressive, however with the addition of roll fed wide format, UV Flatbed and DTG and you begin to appreciate that Ricoh offers a serious range amongst digital technologies. The fact the Customer Experience Centre is also an ISO certified print shop where all of Ricoh’s print needs are met truly connects them to the significant issues faced in commercial, wide format and DTG textile decoration.

On site we were joined by Ellie Koury and Clement from Alwan to see a demonstration of their newly launched Colour Tools software built around spectral ICC profiling and automated colour management. When you consider that the standard patch set to create an ICC profile is over 1,000 patches, achieving a quality profile with 48 patches demonstrates something of the promise and power of spectral colour management. Ellie explained the principle behind Hydra Profiling which I’m going to have to save for another blog.

Needless to say, following the meeting, Paul and Jason put the process through it’s paces and managed to produce a well-ordered profile using 48 patches in a matter of minutes. When you consider the efficiency improvement where you’re creating multiple profiles, the savings justify the investment.

FESPA’s new colour management feature, COLOUR L*A*B* will be introduced for the first time at Global Print Expo 2019 in Munich. It is aimed at helping visitors improve colour management practices in their own print businesses. The feature provides a walk-through showcase of representative technologies from a range of specialist suppliers, live demonstrations, guided tours of the exhibit, and educational presentations from subject matter experts. Visit and discover the features. Please use promo code FESG902 to register for free.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

Personalisation: From mass production to print-on-demand

Technological advancements are driving the growing trend of personalisation, fueled by consumer demand for unique products. From packaging campaigns like Share-a-Coke to customised apparel by Nike and Adidas, and AI-powered tools, the shift from mass production to print-on-demand is evident. The SmartHub Conference at the Personalisation Experience from 6 - 8 May will explore these opportunities and challenges for businesses.