Colour management policies for clients

Paul Sherfield discusses the next step in colour assurance and client satisfaction.

Let’s assume that all your colour management systems, software, workflows and internal policies are in place and working after reading the many pieces on this subject on the FESPA web site.

You understand the importance of making device profiles for each substrate, your have a number of ‘output’ or ‘simulation’ profiles, usually based on an ISO printing standard and profile, such as ISO coated v2 (Fogra 39), (PSO coated v3 (Fogra 51) or the uncoated profiles based on Fogra 47 and Fogra 52.

You may even have some colour managed workflows to the maximum gamut of your device and chosen substrates. Therefore, matching to an offset litho, or other standard to maintain a ‘Common Colour Appearance’ over a client’s project that includes many differing printing methods and substrates holds no issues. And when required, and the device and substrate allow, the widest CMYK colour gamut can also be used.

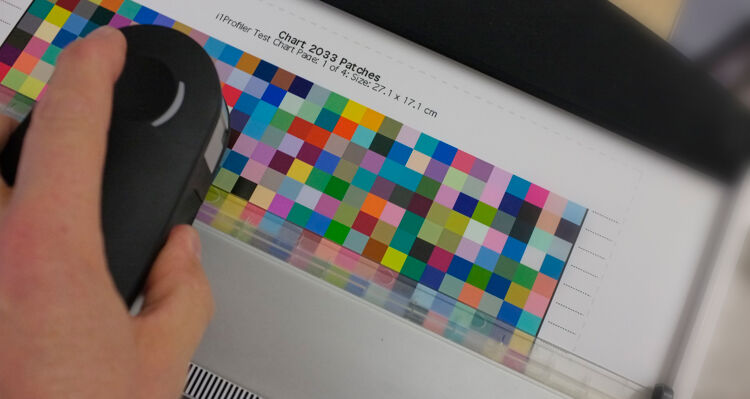

It’s possible you even ‘validate’ your output to the chosen colour workflow using a process control system to insure accuracy, either daily or even on a job-by-job basis.

So, you’re now totally in control of your process and colour? What gaps could be left in the colour managed workflow?

Often the ‘colour’ gap is in the files, PDF’s etc, supplied to you by clients! Do they meet your colour management expectations? Do they have the correct CMYK icc profile for your colour managed workflows? What information do you give to clients in this area?

You hopefully you do preflight clients file, which should include checking for the correct CMYK icc profile or outputintent in a PDF X. Other colour preflight areas should include, checking the resolution of images and RGB images.

If the CMYK profile is wrong, what can you do.

It is worth remembering that client files with a CMYK colour profile that does not match your colour management workflows and is printed without being repurposed, then the colour could change and not meet your client’s expectations.

A number of things, correct it yourself using colour server software, set to change PDFs and images to your colour managed workflows. These often use advanced devise ink icc profiling methods repurpose CMYK images very accurately and also deal with RGB conversions to the correct CMYK profiles.

This then gives a correctly colour managed file in line with the requirements of your colour management policies and workflows.

Another, perhaps more proactive solution it to encourage your clients to produce their PDFs and file to your colour management policies. This can be achieved by publishing details of how you wish files to be prepared, your colour management policy and the icc profiles and settings to use.

This could be published on your web site together with a download area for resources such as icc CMYK profiles, Adobe CC color settings files (.csf) and PDF job options settings (.joboptions).

This would then enable your clients to work to your setting and methods. Often training can be offered to the larger clients in this area, which also serves as a value-added service and is excellent for client retention. This results in files that need no intervention and are correct for your workflows.

The route you take to ensure that client files are produced to your colour management policy will depend on your market and client requirements. It you are not able to access the file creators, or the client expects you to use your colour expertise, then a solution is needed to repurpose client’s files and PDFs.

Often a combination of both approaches is required to both meet all client needs and ensure that your colour management works from client’s files to printed product.

FESPA introduces new Colour L*a*b* Colour Management feature at FESPA Global Print Expo 2019, a new technology showcase and supporting conference programme designed to help visitors improve colour management practices in their print businesses. For further information about FESPA Global Print Expo 2019 and to register, visit www.fespaglobalprintexpo.com. Use code FESM901 when registering for free entry.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

How to grow your business with white ink applications

Opaque white ink is revolutionising signage, vehicle graphics, wallcoverings, short-run and wood packaging, and window blinds by enhancing vibrancy and clarity. This enables printers to offer high-demand, standout products, boosting profit margins. HP Latex white ink applications and their large format printing solutions will be showcased at FESPA 2025 in Berlin.