RedBOND Composites commits to Sustainability with new plan

RedBOND Composites is an European aluminium composite manufacturer for digital printing and visual communication. Two years ago, RedBOND launched a wide Sustainability Plan to highlight its great respect for people and the environment.

RedBOND perceives sustainability as a business model that should be included from the design of its production lines and the eco-design of its products, with the aim of minimising waste as much as possible, manufacturing in a more efficient way and boosting Circular Economy by recycling and giving scrap a new life. All this, subject to a working environment that encourages the promotion and growth of people, aligned in values and objectives.

RedBOND is green industry and proves it in every action:

REINDUSTRIALISATION

Since the beginning of its activity, it has consistently invested in infrastructure and machinery, launching innovative and exclusive products worldwide.

In 2012, RedBOND started up its technologically advanced and highly optimised first production line, generating barely any waste. In 2018, the company installed its second production line to expand the product range and enter new markets. In 2022, RedBOND built a new 1.080 m2 warehouse to improve and increase its export capacity, including sea containers to improve their export capacity to other continents.

Credit: RedBOND

Credit: RedBOND

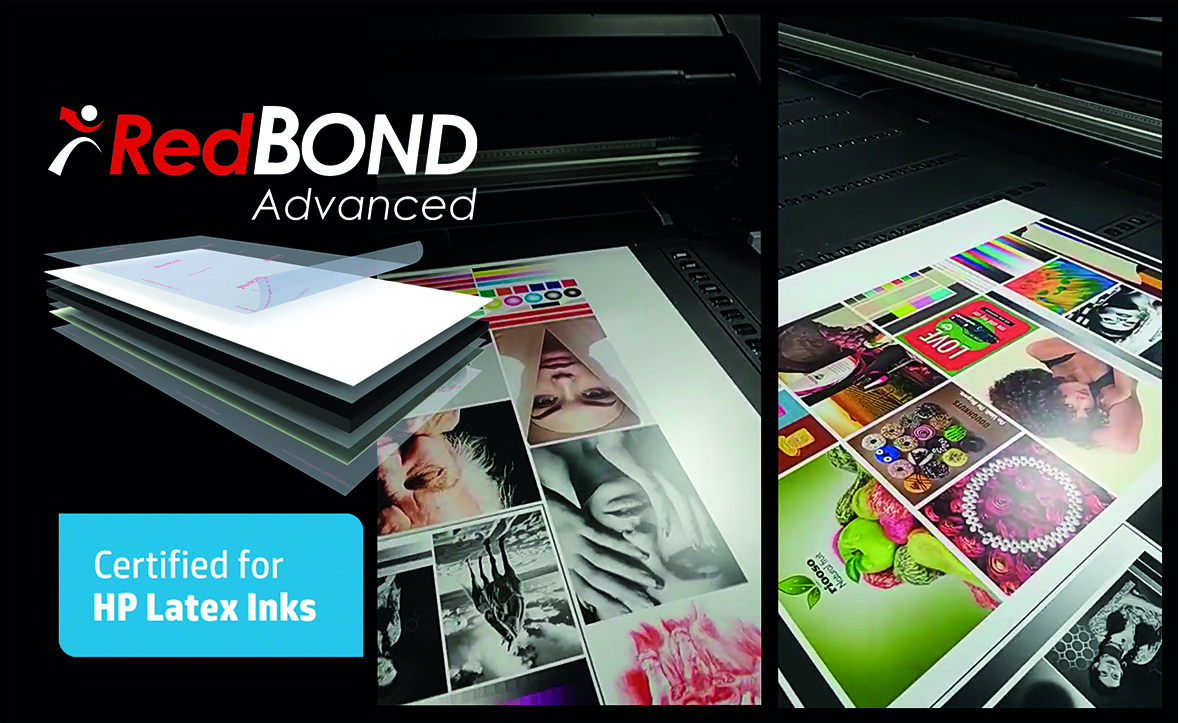

INNOVATIVE DNA

Across all of its departments, RedBOND is focused on continuous innovation to improve competitiveness and offer greater value to all their customers. In 2016 it launched RedBOND Ultra Lite, a unique European panel for its aluminium thickness of 0.08mm, especially for flat applications. In 2020, it launched RedBOND Advanced product range for eco-friendly inks, becoming the first manufacturer worldwide to be certified by the US multinational HP for its latex inks. In 2021, during COVID-19, it launched the RedBOND Sanitary antibacterial panel, specially designed for places that require the most stringent hygiene and cleaning conditions.

Credit: RedBOND

Credit: RedBOND

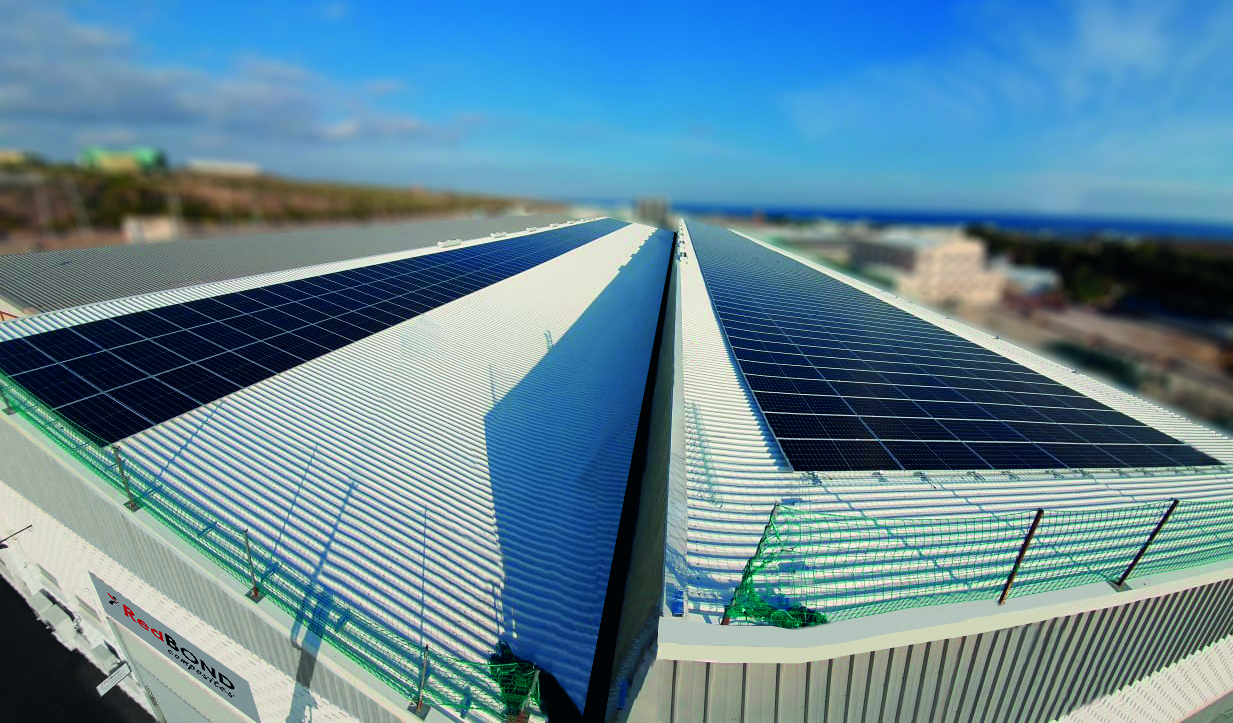

GREEN ENERGY FOR SUSTAINABLE MANUFACTURING

The business has made several investments aimed to reduce energy and water consumption, drastically reducing the carbon footprint and waste generated in the production process.

RedBOND promotes the reduction of consumption through improvement plans where all staff are involved through Lean Manufacturing methodology and ensure they optimise of all resources.

In 2016, it installed new stainless-steel tanks that have led to a reduction in water consumption of more than 60%. At the beginning of 2022, RedBOND implemented a photovoltaic installation for self-consumption that provides environmental benefits equivalent to avoiding the emission of 200 tonnes/year of CO2 into the atmosphere and the planting of 400 trees.

Credit: RedBOND

Credit: RedBOND

ZERO WASTE FACTORY

In 2022, RedBOND became the first European manufacturer of aluminium composite panels to obtain the Zero Waste Certificate, which certifies that more than 94% of the waste generated by its production activity is recycled and converted back into raw material. At the end of 2022 it also obtained the "Calculo & Reduzco Certificate" from the Spanish Ministry for Ecological Transition, which certifies the reduction of CO2 emissions into the atmosphere of RedBOND Composites. All products are 100% recyclable, which promotes the Circular Economy.

Credit: RedBOND

Credit: RedBOND

EQUALITY AND TRAINING

RedBOND focuses on the people within their business and continues to invest in staff training in new areas and specific aspects, committed to inclusive, equal and sustained economic growth.

In recent years, RedBOND has doubled its staff and has based the growth of its team on meritocracy, regardless of gender, age, or ethnicity. In addition, it has internal promotion plans for the personal and professional growth of its employees.

All the actions that accompany its Sustainability Plan demonstrate RedBOND's firm commitment to people and the environment, developing and manufacturing sustainable materials and making great efforts to achieve a better world.

Main image credit: RedBOND

Les sujets

Intéressé à rejoindre notre communauté ?

Renseignez-vous dès aujourd'hui pour rejoindre votre association FESPA locale ou FESPA Direct

Nouvelles récentes

Optimiser la personnalisation grâce à la technologie : points de vue des intervenants de la conféren

Personalisation Experience 2025 (6 – 9 mai 2025, Messe Berlin, Allemagne) organise sa première conférence SmartHub du 6 au 8 mai 2025.

Effets spéciaux en DTF : comment les encres néon font ressortir les vêtements

Les encres fluorescentes néon constituent la dernière innovation en matière d'impression DTF. Elles offrent des effets éclatants et accrocheurs, aussi bien à la lumière du jour qu'aux UV, offrant ainsi aux décorateurs de vêtements un avantage concurrentiel. Les tests démontrent une bonne résistance au lavage, même si la perception de la valeur ajoutée par le marché est encore en développement. Grâce à son adoption croissante et aux avancées technologiques constantes, le néon représente une avancée significative pour la personnalisation créative.

Exploiter les opportunités de croissance dans le secteur des vêtements personnalisés imprimés

Le secteur des vêtements personnalisés imprimés est en plein essor et devrait atteindre 10,1 milliards de dollars d'ici 2030. Portées par le désir d'expression personnelle des consommateurs et leurs besoins en matière de branding, les avancées technologiques telles que le DTG/DTF et l'intégration du e-commerce sont essentielles. Le développement durable, les matériaux écologiques et l'impression à la demande sont des moteurs de croissance essentiels. Les entreprises qui exploitent ces tendances, notamment l'IA et les réseaux sociaux, disposent d'un potentiel commercial important.

Personnalisation : de la production de masse à l'impression à la demande

Les avancées technologiques stimulent la tendance croissante à la personnalisation, alimentée par la demande des consommateurs pour des produits uniques. Des campagnes d'emballage comme Share-a-Coke aux vêtements personnalisés de Nike et Adidas, en passant par les outils basés sur l'IA, la transition de la production de masse vers l'impression à la demande est évidente. La conférence SmartHub, organisée lors de la Personalisation Experience du 6 au 8 mai, explorera ces opportunités et ces défis pour les entreprises.