How you can profit from 3D printing

Printing is no longer limited to flat surfaces. With the help of 3D printers, impressive objects can be manufactured right from a digital file, unveiling a whole new world of opportunities for creative professionals and laymen alike.

The audience was not likely to have been afraid of ghosts, but stopped and stared anyway: September 2016 saw “Ghost Busters” busses carrying the iconic ‘No-Ghost’ Logo in 3D print, each about 4.3 meters high, through major US cities. They had been commissioned for this year’s not so very successful summer movie by its production company Sony Pictures.

“Visually appealing bus wraps are not a new application area for companies like ours, but the capability to offer 3D printed versions takes that application to new creative frontiers”, said Moshe Gil, founder and CEO of Carisma, a New York-based print service provider.

His company is one of the first to commercially use the Massivit 1800 3D Printer, showcased to the wider public at FESPA 2017 in Hamburg. Still, “Ghost Busters” was not their first 3D printed bus wrap project. Just a few months before, they produced similar visually striking project for The Angry Birds Movie. Other 3D printing clients outside the entertainment circuit include Macy’s, Disney and Samsung.

Who Ya Gonna Call?

September 2016 saw “Ghost Busters” busses carrying the iconic ‘No-Ghost’ Logo in 3D print, each about 4,30 meters in height, through major US cities. Photo: Massivit

The Massivit 1800 3D Printer, taking advantage of the company´s proprietary GDP (Gel Dispensing Printing) technology, is able to produce high quality 3D pieces up to 1.8 m in size.

The UV-curing gel will harden within moments, thus making nonvertical and hollow object printing possible, doing away with the often massive support structures that make many large 3D printed objects too heavy and thus impractical for most Point of Sale (POS) promotion and advertising use cases.

Having to apply less material also dramatically lowers printing time for large-scale 3D structures from many days to (still quite a few) hours. As of today, the Massivit gel technology only allows for one uniform colour, so full colour objects still have to be handpainted or airbrushed for a photorealistic look, adding more costs.

This Is Big

Berlin-based start-up BigRep ́s One printer features a build volume of one cubic meter. Photo: BigRep

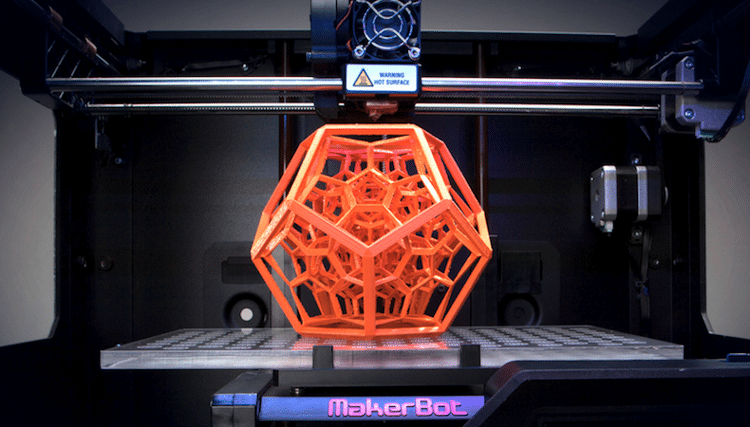

While Massivit’s UV gel technology is unique, there are other 3D printer manufacturers that aim big: Berlin based start-up BigRep’s One printer features a build volume of one cubic meter. They rely on “filament” technology, basically big spools of thermoplastic materials. The filament is heated and, once in liquid state, applied through print heads layer by layer to create the object.

The filament technology is very widely used in 3D printers for home and professional use, but it does come with some disadvantages. As the molten substance does take its time to finally harden, for many designs massive walls and/or support structures are necessary to prevent the whole piece from collapsing during the printing process, delaying completion.

Thus big filament 3D prints (which may also be assembled from multiple parts) could easily take several days to make. Once printed, the 3D object is not ready for the big time yet. Depending on the printing mode, resolution is quite low, so some trimming and de-burring is often required.

Filaments are available in various qualities, including some that make the surface look like wood or metal, but it is only possible to print solid colours, usually one or two at a time, which cannot be mixed and which don’t allow for halftones. No disadvantage without an advantage, though: filament-based 3D prints usually are quite robust and sturdy and suitable for outdoor use.

Mini-Me

This little guy, about 20 cm in height, takes about 17 hours to print with an entry level filament 3D printing system.

Just a few years back, almost every major High Street was home to a 3D printing parlour, where people flocked to have their full colour Avatars printed after a 3D scan that was part of the package. The 3D printing technology used there is called “powder bed and inkjet heads 3D printing” (3DP), allowing for four colour (CMYK) figurines.

In a nutshell, water based inks and binder are jetted onto a bed of powdered polymers or plaster, creating small scale figurines layer after layer. Although the resolution as well as colour gamut of 3DP prints is still not very satisfying, having your Avatar printed usually does not come cheap, as printing even smallscale figurines will take several hours.

Sometimes a varnish is applied after printing, still 3DP prints are rather breakable and not generally recommended for outdoor use. 3D printing parlours, it is now safe to say, did not live up to their commercial expectations, probably due to a significant gap between price and expected print time and quality.

There are quite a few more methods of 3D printing, including some that print with powdered metals, which are already having a big impact on the jewelry industry. 3D printers have so far jetted sugar and chocolate at pastry shops, as well as pasta dough occasionally, opening up a wide range of creative applications particularly in the advertising industry.

For instance brand names, can be printed as confectionery and bags of noodles customised. So far, most of these applications are still very much niche. This might change when HP´s Jet Fusion 3D printing ecosystem begins to really impact the market, as it will rely on partners like Evonik, a specialty chemicals company, to develop a wide range of printing supplies with distinct qualities.

The first commercial units of the HP Jet Fusion 3D 4200 were shipped in mid-December 2016 to development partners including Jabil Inc, a supply chain management and electronic manufacturing company, and Shapeways the world's largest online 3D Printing Service.

Is the Future Now?

For professional and personal creative projects, it is perfectly possible to send your data to specialised print service provider like Shapeways, to have it 3D-printed in various materials. You just have to upload your .STL or .AMF files from a CAD or 3D modelling software, use an online 3D creation tool, or search for the required data at an online 3D warehouse.

For the visual communications industry, however, 3D printing is very much a pioneer market. Skilled 3D modelling staff are scarce, price and delivery times for 3D printed objects will vary greatly, depending on time, material and place. It is therefore more important than ever to find an experienced service provider you can trust with your 3D project.

Thema

Sind Sie daran interessiert, unserer Community beizutreten?

Erkundigen Sie sich noch heute über den Beitritt zu Ihrer örtlichen FESPA-Vereinigung oder FESPA Direct

Jüngste Neuigkeiten

Branchenexperten untersuchen die Entwicklung der intelligenten Fertigung in der Textilindustrie

Im Rahmen der Personalisation Experience 2025 diskutierte ein FESPA SmartHUB-Roundtable die transformativen Auswirkungen der intelligenten Fertigung auf die Textilindustrie. Experten betonten den Wandel hin zur bedarfsgerechten Individualisierung, der durch Digitaldruck, Datenanalyse und Automatisierung vorangetrieben wird. Zu den wichtigsten Erkenntnissen zählten eine verbesserte Maschinensteuerung, eine deutliche Abfallreduzierung durch intelligente Software und Farbmanagement sowie eine verbesserte Nachhaltigkeit durch Energieeffizienz und Nearshoring, die Flexibilität und Umweltverträglichkeit in der Textilproduktion gewährleisten.

FESPA 2025 versammelt führende Visionäre der Spezialdruckbranche in Berlin

Die FESPA Global Print Expo 2025, European Sign Expo und Personalisation Experience (6.–9. Mai 2025, Messe Berlin, Deutschland) hieß Visionäre aus der gesamten Spezialdruckbranche willkommen, um die Zukunft des Drucks zu gestalten, zukunftsweisende Geschäftsstrategien zu entwickeln und innovative Wege zu erkunden, um aufkommende Branchentrends in konkrete Wachstumschancen umzusetzen.

Entdecken Sie innovative Textildrucklösungen mit Adobe Print Engine 7

Die auf der FESPA Global Print 2025 vorgestellte Adobe PDF Print Engine 7 bringt den Textildruck deutlich voran. Debbie McKeegan erläutert, wie sie die Verwaltung nicht-weißer Substrate und die RGB-Farbverarbeitung automatisiert, Farbräume durch In-RIP-Mehrfarben-Transparenzmischung erweitert und Arbeitsabläufe für mehr Effizienz und Nachhaltigkeit optimiert. Das Update fördert die Individualisierung, reduziert Abfall und positioniert Unternehmen an der Spitze der Innovation im Digitaldruck.

FESPA Global Print Expo 2025 – Allgemeine Highlights

Die FESPA Global Print Expo, Europas führende Fachmesse für Druck und Beschilderung, kehrt vom 6. bis 9. Mai 2025 in die Messe Berlin zurück.