Epson’s Monna Lisa digital technology solves the textile industry’s traditional, unsustainable problems. It offers superior precision and colour accuracy (1,440x faster matching) alongside massive environmental gains, cutting water use by up to 96% and energy by up to 80% (with pigment ink). This advanced, on-demand printing is the future of profitable, sustainable production.

Traditional analogue printing processes have held the textile industry captive for decades, perpetuating a cycle of environmental destruction and economic inefficiency. The statistics are real: conventional textile production consumes excessive water resources, generates substantial energy demands, and creates mountains of unsold inventory that ultimately end up in landfills or sold at devastating losses.

This approach doesn’t just harm the environment—it destroys profitability and stifles innovation.

With environmental regulations tightening and consumer demand for sustainable products accelerating, traditional screen-printing methods are rapidly becoming obsolete. The question facing print professionals isn’t whether to embrace digital transformation—it’s whether their chosen technology will deliver the precision, sustainability, and economic viability required to succeed and meet market demands.

After an extensive technical review of the Epson Monna Lisa series at their Innovation Centre in Paris, which was delivered by Madjid Hammadou, Epson France – Presales Engineer, one thing becomes crystal clear: this isn’t merely an evolution in digital textile printing—it’s a complete reimagining of how precision engineering can solve the industry’s most pressing challenges.

Design and Colour Precision: Engineering Excellence at the Source

The foundation of any superior textile printing operation begins with colour accuracy and design precision. Epson’s Edge Print software demonstrates how advanced colour management transforms the creative process from guesswork into science.

The system’s sophisticated colour management capabilities include both input and output profile selection, with options for generic and custom profiles that enable unprecedented control over colour reproduction. The rendering options—relative colorimetric and perceptual rendering—manage colours within and outside the gamut, optimising colour balance and gradients with mathematical precision.

The breakthrough lies in the colour replacement feature combined with SD10 spectrophotometer integration. This technology reduces colour matching time from an entire day to just one minute—a 1,440x improvement in efficiency that directly impacts production capacity and customer response times.

Revolutionary Printing Technology: Precision Core Engineering:

The printing process itself reveals where Epson’s engineering excellence truly differentiates their technology from inferior alternatives. The ML8000 and ML13000 represent two distinct approaches to solving different production requirements, both leveraging Epson’s heat-free Precision Core piezo printhead technology.

Head Technology Innovation: Each ML-13000 print head contains 3,200 nozzles (800 nozzles per chip across four chips), totalling 25,600 nozzles for the ML8000, and 41600 for the ML13000 per machine. The heads are arranged symmetrically to enable bi-directional printing whilst eliminating colour banding issues—a critical advancement for maintaining colour fidelity across fabric widths.

The nozzle verification technology (NVT) represents a quantum leap in preventive maintenance. By using electrical signals to detect clogs before printing begins, the system eliminates the costly downtime and waste associated with traditional reactive maintenance approaches.

Dynamic Alignment Stabilising Technology (DAS): The impressive Dynamic Alignment Stabiliser manages every dot individually, controlling waveforms on each print head to improve dot placement accuracy and achieve uniform dot density. This isn’t simply about preventing defects—it’s about delivering consistent colour management and gamut control across entire production runs.

The High Accuracy Head Alignment Technology (HAAT) system, combined with RGB camera alignment, ensures print head positioning remains precise throughout extended production cycles. These features offer engineering solutions to real production challenges.

Ink Technology and Versatility: Optimising the Genesta ink range—pigment, reactive, acid, and dispersed—the ML8000 addresses every fiber requirement.

Whilst the ML13000 delivers a further strategic advantage for pigment ink printing. With appropriate pre-treatment, pigment ink enables printing on nearly all fibers (synthetic, artificial, and natural) through a single-step process.

The ML-13000’s pigment-only configuration represents the pinnacle of simplified production: printing, curing, and finishing occur in one integrated process. Meanwhile, the ML8000’s multi-ink capability (acid, reactive, pigment, and dispersed) provides maximum flexibility for diverse production requirements.

Drying and Finishing: Controlled Environment Excellence

Traditional textile finishing processes are environmentally destructive and technically inconsistent. Epson’s approach fundamentally reimagines this critical production phase through precision environmental control.

Advanced Drying Technology: The hot air-drying system operates without surface contact, preventing the colour drops and handle changes associated with many calendering processes. This contactless approach maintains fabric integrity whilst achieving consistent drying results.

The system’s environmental controls temperature and humidity management to ensure stable conditions throughout the printing process. This isn’t luxury equipment; it’s essential technology for achieving consistent, repeatable results in industrial production environments.

Integrated Fixation Systems: For pigment inks, the minimum two-to-three-minute fixation process occurs inline, eliminating separate processing steps and associated handling costs. The overcoat application enhances fixation and fastness properties whilst maintaining the fabric’s natural handle.

The inline fixation capability of the ML-13000 pigment solution represents a significant advance in production efficiency, eliminating the bottlenecks and quality variations associated with separate finishing processes.

Environmental Security and Measurable Sustainability Gains

The environmental advantages of these technologies deliver quantifiable operational improvements. Digital technology utilising pigment ink reduces water consumption by up to 96% and energy consumption by up to 80% compared to traditional analogue processes.

Water Management Innovation: The ML13000’s closed-circuit water recycling system represents engineering excellence applied to environmental challenges. Without recycling, printing operations consume 70-100 litres of water per hour. The automated discharge and replenishment system maintains water quality whilst dramatically reducing consumption.

The belt washing system continuously cleans the sticky belt during printing, removing ink and lint automatically. This isn’t just about cleanliness—it’s about maintaining consistent print quality whilst minimising waste.

Sustainable Ink Technology: Pigment inks are non-toxic and safe for discharge into manufacturing facility streams, eliminating the hazardous waste management requirements associated with traditional textile printing chemicals. This simplifies regulatory compliance whilst reducing environmental liability.

Strategic Implications: Future-Proofing Production Capabilities

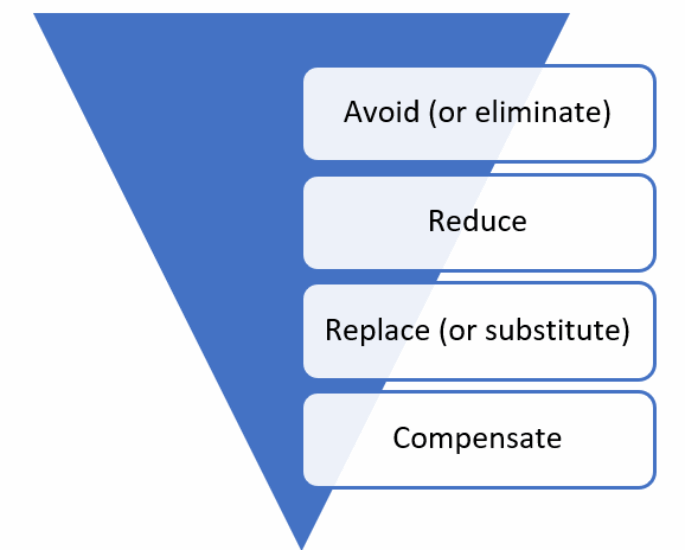

The technical capabilities outlined above solve immediate production challenges, but their strategic value extends far beyond current requirements. The textile industry’s future demands on-demand production capabilities that eliminate overproduction waste whilst maintaining quality standards.

On-Demand Production Enablement: Digital technology enables producing only what has been sold, eliminating the massive inventory waste endemic to traditional textile production. The ML13000’s versatility—handling various fabric widths, types, and even single leather pieces up to five millimetres thick—supports the customisation demands of modern markets.

The remote monitoring capabilities, including Moverio glasses for specialist support, ensure consistent operation across distributed production networks. This technology infrastructure supports the localised production models that will define competitive advantage in sustainability-conscious markets.

Embedded Precision Engineering That Defines Competitive Position

The precision engineering embedded throughout Epson’s Monna Lisa series represents more than incremental improvement—it’s the technological foundation required for competitive advantage.

The textile printing industry’s transformation isn’t optional—it’s inevitable. The only question facing print professionals is whether their technology choices position them as leaders or leave them struggling with obsolete processes.

Epson’s Monna Lisa technology represents precision engineering applied to solve real textile production challenges whilst delivering measurable environmental improvements. This isn’t about keeping pace with change—it’s about leveraging technological excellence to define competitive advantage.

The businesses that thrive in tomorrow’s market will be those that recognise superior engineering when they see it and have the strategic vision to implement it before their competitors.