As a growth segment in digital printing, Industrial Inkjet (IIJ) is still a popular technology. Sonja Angerer discusses the technologies, the advantages and disadvantages of industrial inkjet and the market opportunities for print shops in IIJ.

Industrial Inkjet refers to the use of inkjet printing technologies in industrial applications. These can be different environments to produce mass products, but also individualised goods and even individual pieces. In addition, the use of inkjet printers for marking is often referred to as “Industrial Inkjet”.

Using Industrial Inkjet

Industrial Inkjet is used in a wide range of industries, including:

- Consumer Goods Industry: IIJ is mostly used to produce sample pieces or small batches such as glass splashbacks. However, inkjet printers are also increasingly being used to produce large quantities, for example for floor coverings and tiles.

- Packaging industry: This is where IIJ is used to print barcodes, serial numbers, best-before dates and other important information directly on to packaging.

- Electronics: In electronics manufacturing, IIJ is used to mark printed circuit boards and electronic components.

- Textile industry: IIJ allows patterns and designs to be printed on textiles roll-to-roll without the need for stencils or printing plates. In addition, apparel can be easily decorated with the help of inkjet technologies, e.g. for sportswear, workwear or merchandise.

- Medical technology: IIJ is used to provide medical devices and packaging with important information, e.g. in Braille.

- Automotive: This is where IIJ is used to mark parts and components, facilitating traceability and quality control.

Digital carpet printing enables impressive, colourful motifs without repeat.

Image Credit: S. Angerer

Technologies in Industrial Inkjet

In graphic printing, Continuous Inkjet (CIJ) has largely been replaced by fast single-pass heads. But Continuous Inkjet is still quite common in packaging printing as well as in marking e.g. with Videojet modules.

When printing on carpet and other high-pile textiles, micro-nozzles are used instead of inkjet heads, ready to apply the high amounts of ink required to dye thick textiles in Chromojet systems from Zimmer Austria.

However, Piezo Drop-on-Demand heads are very common in Industrial Inkjet applications today. For very high speeds, single-pass heads are often used, i.e. print heads that only need one pass to create the design on the surface. Multi-pass heads are often installed in large numbers in Industrial Inkjet modules to achieve very high productivity.

Depending on the application, industrial customers may choose a standard machine, like models for the graphic arts industry, such as the Durst Alpha series. They can also purchase custom print modules for installation in production lines, e.g. from Thieme, or heads and development environments for in-house development, e.g . from Konica Minolta.

There are also special machines available for individual Industrial Inkjet applications, e.g. EFI Cretajet printer for the production of ceramic tiles with décor.

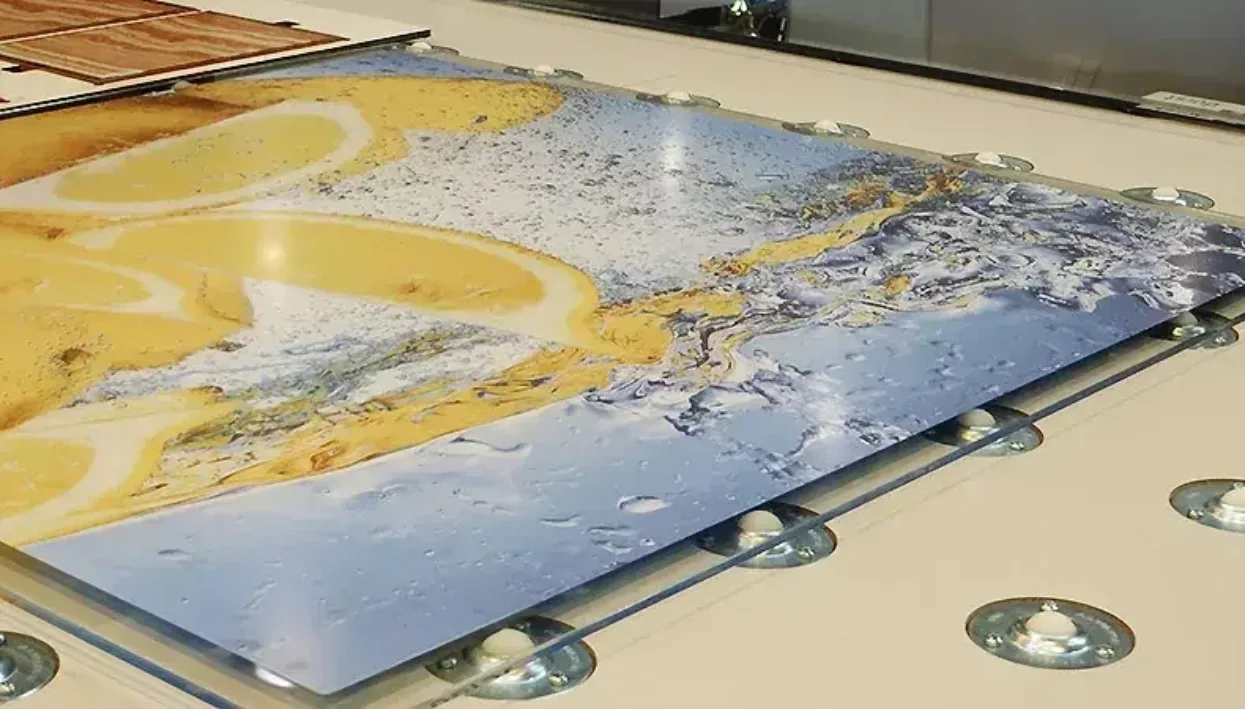

Flooring such as click laminate is often produced with the help of Industrial Inkjet.

Image Credit: S. Angerer

Does Industrial Inkjet replace other technologies?

Industrial Inkjet is increasingly is being used more regularly than traditional analogue printing technologies such as screen, pad, flexo and offset printing. In some cases, other coating and dyeing processes are also being replaced. This is because digital technology makes it possible to dispense with print templates and stencils. This simplifies the production of consumer and capital goods, making manufacturing more flexible and faster.

Both direct printing and transfer processes with inkjet are used in Industrial Inkjet. In most cases, however, a digital printer or a print module is only a small part of an extensive production process.

If IIJ replaces an analogue printing process with a digital one, it may not have such good advantages. This is because inkjet inks are almost always significantly more expensive than fluids for traditional printing. Therefore, when IIJ is used, processes and product portfolios often need to be significantly adapted and changed.

Advantages and disadvantages of Industrial Inkjet

Although Industrial Inkjet has completely changed individual segments such as the production of high-quality tiles within a few years, there are also disadvantages. For example, the ink consumption can be quite high, especially for large-area prints.

An Industrial Inkjet printer, like an inkjet printer for the graphic arts industry, must be maintained regularly, which can add considerable costs. In addition, inkjet printers struggle with very vibrating, dusty, hot or very cold environmental conditions.

Therefore, Industrial Inkjet printers must be protected within some challenging production environments. This is usually achieved through a separate, air-conditioned room. However, this generates high costs. These are in addition to the sometimes very high prices for the printer itself.

However, it is the undeniable advantages of Industrial Inkjet that has led to inkjets largely replacing analogue technologies in many industries. This is because IIJ can print on a wide range of materials and surfaces, including uneven and curved substrates that can otherwise only be processed with pad printing.

Inkjet technology offers a high print resolution and a precision that is impossible or very difficult to achieve with analogue processes. Digital printing also enables multi-coloured and repeat-free designs that cannot be reproduced using traditional processes.

In the future, inkjet printing will also be used more and more frequently in the production of consumer goods.

Image Credit: S. Angerer

The future of Industrial Inkjet

The popularity surrounding Industrial Inkjet has reduced to some extent in the printing industry. It is often not easy for printers to gain traction in the segment. Industrial companies do continue to consider or use inkjet technology to produce consumer goods. However, they often do not understand themselves as part of the printing industry.

IIJ has nevertheless established itself as a versatile and efficient printing technology that is used in many industries. In the future, the technology will certainly continue to improve. Advances in materials science and nanotechnology could lead to even more precise and efficient printing processes. In addition, the integration of Industrial Inkjet will further advance the automation of production processes.

Some highly specialised printers have managed to establish themselves as producers of consumer goods or as IIJ suppliers. In most cases, these are companies that have already offered analogue printing services specifically for industry, e.g. in screen printing.

Many manufacturers of graphic inkjet printers also offer product lines for industrial inkjet, especially in the areas of roll-to-roll textile printing as well as for the production of floor coverings and printed glass. For most medium-sized print shops, however, Industrial Inkjet is likely to remain a niche topic in the future.

To discover the latest content that covers a wide range of sectors including inks and digital printing sign up for FESPA’s free monthly newsletter FESPA World available in English, Spanish and German.