Hybrid production merges screen printing’s strength for durable, thick-layer specialty inks and primers with digital printing’s efficiency for short runs and variable details. This combination maximizes quality and efficiency, enabling complex graphic and industrial applications like textiles, packaging, and electronics, which are often difficult with a single technology.

Hybrid production combines screen printing and digital printing, a process that required the two previously competitive technologies to converge. Historically, digital printing absorbed much of the print volume from screen printing, leading to friction where digital specialists viewed analogue methods as dated, and screen printers criticized early digital print quality. Now, they are reconciled to maximize efficiency.

CAPTION: Hybrid production is often used in textile and industrial printing today. Photo Credit: Sonja Angerer

CAPTION: Hybrid production is often used in textile and industrial printing today. Photo Credit: Sonja Angerer

This slowly began to change in the late 2010s with a new generation of print shop owners and employees, and their respective customers. After all, today’s print buyers are less inclined to speculate about digital or analogue printing but demand cost-efficient products that meet their requirements.

Both screen and digital printing have unique strengths and weaknesses. Recognizing this, many specialist printers now use both screen printing equipment and digital machinery side-by-side in their production halls.

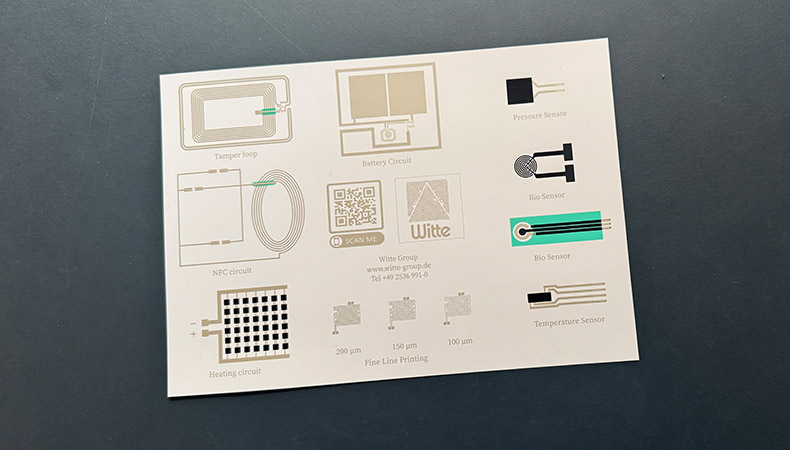

CAPTION: Printed electronics often require a combination of screen printing and digital printing. Photo Credit: Sonja Angerer

CAPTION: Printed electronics often require a combination of screen printing and digital printing. Photo Credit: Sonja Angerer

Advantages and disadvantages of screen printing and digital printing

As an analogue process, screen printing requires print templates, even if the stencil making process has become easier, faster and more environmentally friendly over the decades. However, making screen printing frames ready for production is costly and somewhat time-consuming. For small print runs, analogue set-up costs quickly exceed economic viability. With today’s growing demand for personalised and individualised products, this is the biggest disadvantage of screen printing.

But screen printing also has many advantages to offer for hybrid production. In screen printing, paints and primers for a wide range of surfaces such as textiles, ceramics, glass and metal are readily available at the world market, and at very affordable prices. With screen printing it is possible to lay down thick layers, resulting in high opacity and colour intensity. Therefore, screen prints are typically more resistant to wear and tear and offer greater outdoor durability than digital prints.

Digital printing does not require print templates, as the image is transferred directly from a digital file. This makes the technology highly suitable for short runs, variable data, personalised prints as well as non-repeat patterns. Especially when printing four or more colours, digital printing quality is often superior to screen printing, as granular details and fine gradients are much easier to achieve.

For digital printing machinery usually only one ink is available, which often works with most materials. This means that there is no time-consuming ink change required, speeding up production by leaps and bounds. However, the poor choice of different inks also is the biggest disadvantage of digital print technology, especially in industrial applications.

Highly pigmented or impasto specialist fluids, which often are available at moderate prices for screen printing, most often cannot be adapted for use in market-leading inkjet heads. If a jet-able solution can be found, inks often are very expensive with printing still slow, as many passes are required to lay down the necessary ink volume onto the material.

CAPTION: Hybrid production is often used in interior printing for wall decoration. Photo Credit: Sonja Angerer

CAPTION: Hybrid production is often used in interior printing for wall decoration. Photo Credit: Sonja Angerer

Hybrid production: a combination of screen and digital printing

Hybrid production combines the advantages of screen and digital printing to maximise efficiency and quality of the printed products. This allows for competitive production costs, as in hybrid processes, screen printing is used for primer, recurring elements of a design and large, plain-coloured areas of paints as well as varnishes. Special fluids, such as conductive pastes for printed electronics, can be easily applied in screen printing.

Variable elements, tiny details and multi-hued gradients are commonly added with digital printing in hybrid production. As a result, processes with screen and digital printing enable complex designs and the products that would be highly difficult, very costly, or just impossible to achieve in either printing technology alone.

However, hybrid production does have its drawbacks. Compared to only digital printing, the ecological footprint is typically significantly larger, as not one, but two machines, with all their respective equipment are required, consuming a lot of energy, water and chemicals. Also, making high-quality hybrid production work requires a great deal of expertise and craftsmanship.

Still, there is often no better and economically viable way to print certain applications than in a hybrid process. It might be complicated, even messy, but still much cheaper and quicker than on a digital printer or with screen printing machinery.

CAPTION: Many packaging applications can be produced faster and more cost-effectively using hybrid processes. Photo Credit: Sonja Angerer

CAPTION: Many packaging applications can be produced faster and more cost-effectively using hybrid processes. Photo Credit: Sonja Angerer

Applications in hybrid printing

Hybrid production with screen and digital printing is used in various industries, including:

- Textile industry: For the production of T-shirts, bags and other textiles that need to be printed both durable and with great details.

- Packaging: In the production of packaging in large quantities, with print runs split up and adapted regionally, seasonally or for promotions.

- Printed interior decoration: for some wallpapers, as well as counter tops and flooring.

- Signmaking: For large-format advertising banners and signs with eye-catching designs and outstanding outdoor durability.

- Electronics: For printing circuit boards and other electronic components where precision and durability are critical.

The future is hybrid

Hybrid production with screen and digital printing offers a variety of advantages in specialty printing. For suitable applications, both the quality and efficiency of print production can be significantly improved, while protecting the environment.

Printers working with hybrid processes often decide to give up varnish and/or white channels in their digital printers. Since these inks can be very tricky, especially if only used sporadically, they also minimise maintenance costs.

Hybrid production is particularly worthwhile where screen printing machinery and knowledgeable workers are already available. However, even printers with no prior screen printing experience might sometimes benefit from acquiring screen printing technology for certain applications. As print customers will often demand even more complex applications in the future, while caring less about analogue or digital, it is safe to assume the hybrid products created with screen and digital printing will be even more in demand in the future.