Screen printing and digital printing are 2 common printing processes in sign-making. But what are the differences between the 2, what are their advantages and disadvantages, and how can printers earn the most money using new technologies?

For a long time, it seemed evident that digital printing would replace most analogue printing processes. Over, the past 30 years, digital printing usually has longer run-lengths in comparison to screen printing. However, currently this seems to have stopped. Therefore, it is time to reevaluate the relationship between screen printing and digital printing.

This article will cover following:

- how screen and digital printing works

- which applications these technologies are used for

- what applications are suitable for screen printing and digital printing

- what the future holds for screen printing and digital printing

Manual screen printing with neon colours at a folklore festival in the USA.

Photo: Elvert Barnes – 11a. Monky.Chicha.Peru.SFF.WDC.5July2015, CC BY-SA 2.0

Screen printing and digital printing: similarities and differences

Screen printing

Screen printing is an analogue printing process in which the stencil artwork is applied to mesh material. The first pioneers of the technology emerged in China and Japan as early as in the Middle Ages. However, in Central Europe, it only fully emerged after the Second World War.

In screen printing, the ink is pushed through the screen with the help of a rubber squeegee and sticks to only the parts of the layer that are not covered by the stencil. This is how the motif is created. A separate template for each colour is required. This applies to designs, solid colours, effect varnishes and any combinations of these. This makes screen printing time-consuming and expensive for short runs.

However, if the cost of the artwork is spread over a long run-length, screen printing is almost unrivalled in terms of cost. This is mainly due to the inks are available at low cost worldwide. Unlike digital printing inks, screen printing inks can be used for any machine with the appropriate technology, regardless of the manufacturer of the hardware. With screen printing very thick layers of paint and varnish can be achieved, which are then extremely durable.

Digital printing

Digital printing is a modern printing process in which a digital image is printed directly onto paper, fabric, or other materials. The first inkjet printers materialized in the second half of the 1970s. Like toner-based digital printing, which began in the early 1970s, the machines were primarily intended for typical office tasks. Due to this, printing was mainly executed on single sheets in formats such as DIN A4.

The first reliable wide format printers were made available just before the turn of the millennium. They not only took run-length from screen printing in the graphic arts industry, but also other analogue processes such as large format photographic prints.

This was because digital printing is very flexible and works well for quick short runs. Compared to screen printing and the classic photo process, it requires less electricity and chemicals on site, as the layer thickness in digital printing is quite low. Screen printing, inkjet prints often offer lower outdoor durability, although this depends heavily on the ink formulation. Today, digital printing can be as inexpensive as screen printing, even for medium runs, but very long runs typically are still cheaper in screen printing.

Large format digital printers for sign making and signage are available in the four process colours, CMYK and white, and in some cases also with extended colour spaces. However, there are only a few spot colours for inkjet on the market. Many manufacturers now offer machinery with clear varnish options, which are also able to create structured surfaces.

Effect varnishes or pastes cannot yet be used with commercial digital printers for sign making and signage. Inkjet print heads require certified fluids. As a result, the choice of suppliers of consumables for machinery is much smaller.

Large-format inkjet printers have snatched up many jobs from screen printing and photography in the past.

Photo: Smokeonthewater – Own work, CC BY-SA 4.0,

Applications for screen-printing and digital printing

Screen printing is particularly suitable for products that require high colour intensity and durability. In addition, standard screen-printing machines for the graphic arts industry can also be used for some industrial applications.

Products made with screen-printing in the graphic industry include:

- T-shirts, sweatshirts, bags, and other textiles

- posters, posters, stickers, and other paper products

- art reproduction

- signs, banners, flags, and other promotional materials

Digital printing is particularly suitable for products that require a high level of detail, flexibility, and customization. Products made with digital printing include:

- photo books, calendars, cards, and other personalized products

- brochures, flyers, catalogues, and other information materials

- labels, packaging, stickers, and other product markings

- art and photo reproduction

- wallpapers, canvases, murals, and other decorative products

Today, more and more printers aim to combine screen and digital printing, uniform areas of colour or white underprint is achieved more cost-effectively and in higher quality with the help of screen printing. Screen printing systems are also indispensable for the pre-treatments, as well as complete or partial print lacquer.

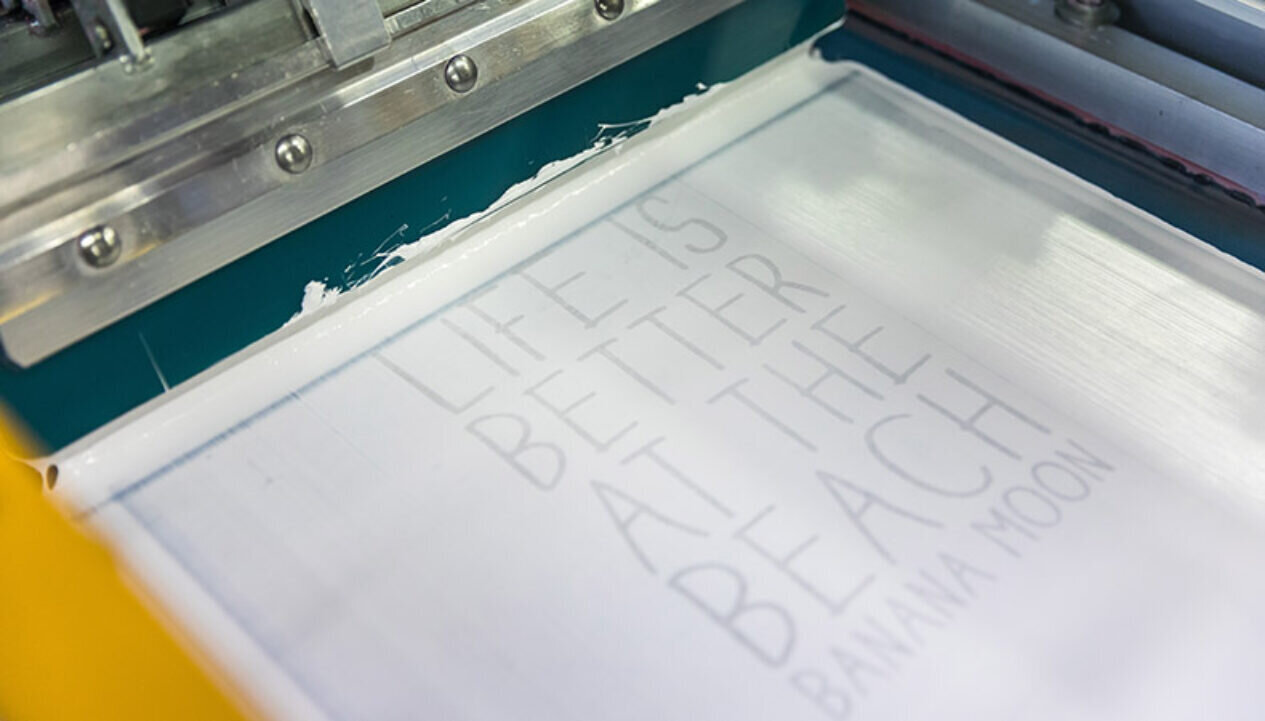

Screen print on stretch textile for swimwear.

Photo: JdessaintBM – Own work, CC BY-SA 4.0

Watch for Screen and Digital Printing

Currently, the rivalry between screen printing and digital printing is now not applicable for printers. Print buyers do not ask for a specific technology anymore. For them, application and price are more important. The following factors determine if screen printing or digital printing is better suited:

- run length

- budget

- design

- durability

In general, screen printing is better suited for large print runs with few colours and simple designs. It offers high quality and long durability at an affordable price. Digital printing is more appropriate when it comes to short runs in photo quality and complex designs. It offers a high degree of flexibility and fast delivery.

However, for very long runs screen-printing remains more cost-effective than digital. That is, if the design is suitable for the technology, e.g., personalized products are not possible to reproduce in screen printing. Nevertheless, there are also applications that are not yet feasible in digital printing, such as fragrance and effect coatings, or high-gloss metallic effects.

What does the future hold for screen printing and digital printing?

Photo: Sonja Angerer

In conclusion, screen printing and digital printing both have their advantages and disadvantages. For printers and sign makers, it is therefore more important than ever to be aware of the advances of both technologies without prejudice and to invest in machines that enable applications that their customers prefer. The application is much more important today than the question “analogue or digital?”.