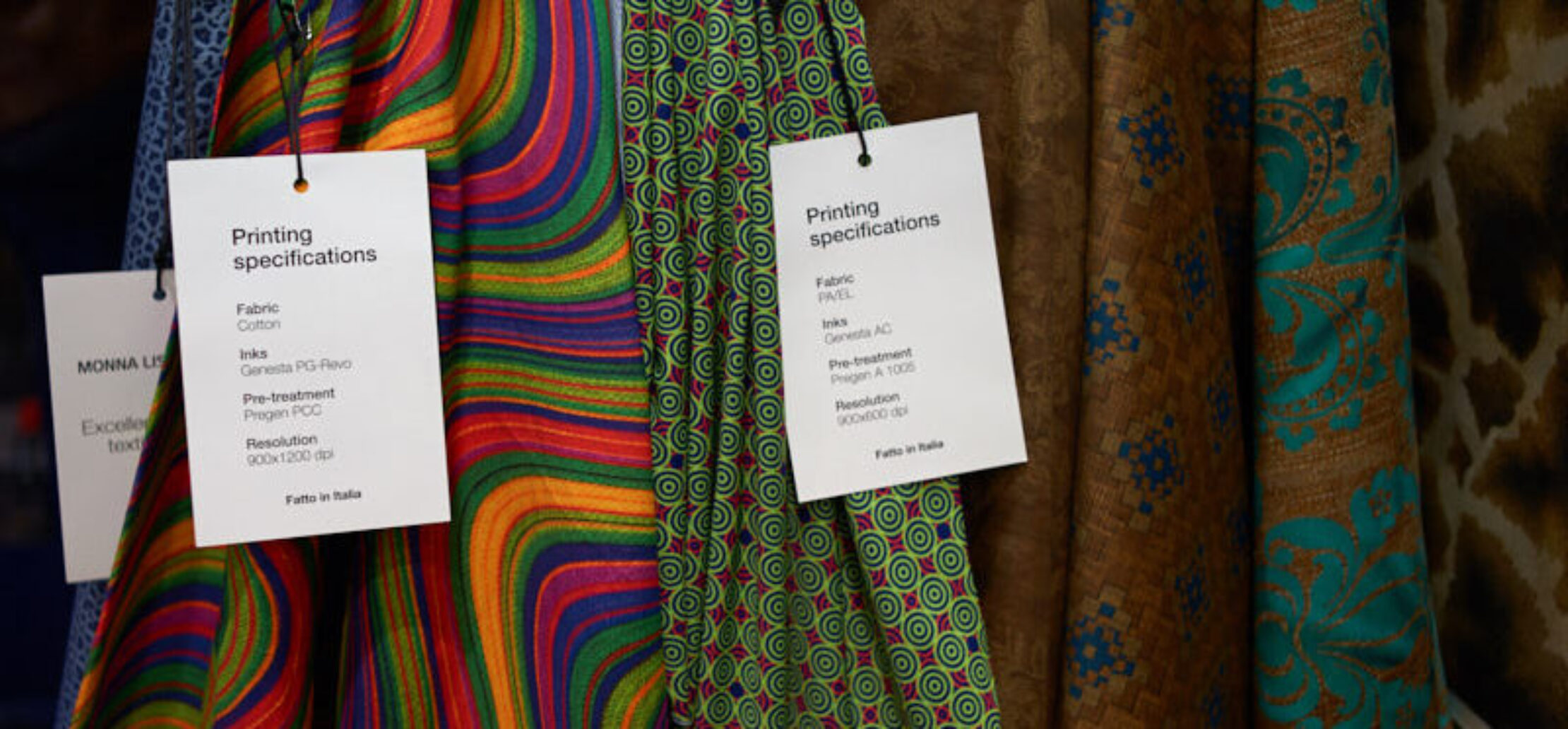

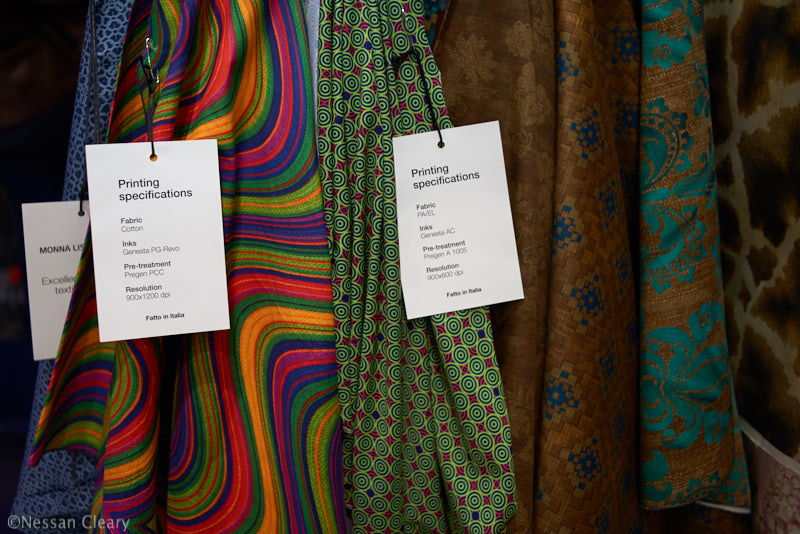

Textiles vary greatly, impacting their handling, printing, and final product value. Understanding natural (cotton, linen, silk, wool) and synthetic (polyester) fibres, their blends, and compatible inks (reactive, pigment, acid dye, sublimation) is crucial. Nessan cleary shares the importance of emphasising fabric quality over just print cost elevates textile printing from a race to the bottom to a realm of high-value applications.

It’s easy to group textiles together as a single family of substrates but the various types of fabric come from diverse roots and require different handling and processing, and are suited for different uses. That has implications for how we print to those fabrics and for the various market applications around textile printing, such as Direct-to-Fabric.

More to the point, the fabric directly affects the value proposition behind the final product. Too often, the conversation amongst print service providers is about the print process, such as the relative costs of DtG or DtF printing. But this just leads to a race to the bottom to use the cheapest textiles with the least expensive printing. And there are other opportunities, from apparel to high end fashion, as well as home furnishings such as duvet covers, where the decoration is a given and the value comes from the quality of the fabric itself.

All textiles can be broken down into either natural or synthetic fibres. As a general rule, natural fibres are softer, lighter and more easily recyclable than synthetics, but synthetics are cheaper to produce and offer features such as crease-resistance and waterproofing. In addition, there are many blends that seek to offer the best of both worlds.

Natural fabrics

Natural fibres further break down into plant-based, which are mainly cellulose, and animal-based fibres, which are mostly protein with a small amount of fats and waxes known as lipids. By far the most common natural fabric is cotton, which grows around the seeds of the cotton plant. It is widely used for t-shirts, socks, underwear and bed sheets. Cotton is also used to make towels and bathrobes, as well as denim and corduroy.

There are several grades of cotton. The cheapest and most common is Regular cotton, where the fibres are twisted together to make the yarn that the cotton is woven from. Most DtG printing uses regular cotton to save costs. A step up from this is Ring-Spun cotton where the strands are twisted and thinned to create soft ropes of cotton fibres so that the final material is softer, lighter and more durable. This also creates a smoother surface that makes for sharper prints. Then there is Combed cotton where the fibres are combed so that they are all parallel and the shorter fibres are removed. This leads to a stronger material with a smoother feel that is suitable for higher value t-shirts and dresses. Finally there is organic cotton, where the cotton is farmed organically, without herbicides or pesticides, which offers a more eco-friendly approach but at a cost.

Linen is sometimes used as an alternative to cotton. It is made from the fibres of the common flax plant, a flowering plant that is also known as linseed. It’s light and strong, very absorbent and dries faster than cotton, which makes it suitable for clothing for warm weather. One downside of linen is that it wrinkles easily but it can also be blended with cotton to create wrinkle-free clothing that is stronger and lighter than linen alone.

Both cotton and linen can be printed with either reactive inks or water-based pigment ink. Reactive inks use dyes that bond with natural fibres but do require post-print steaming and washing. Pigment inks can achieve a similar hand feel but use heat rather than steaming to fix the inks, and don’t require the same degree of washing, which saves on both water and energy. Pigment inks are suitable for both roll-fed and DtG printing.

Many higher value applications, particular in fashion, use silk. This is produced by silkworms, most commonly from the Bombyx mori silkworm that live on mulberry trees. Silk has a reputation for being one of the strongest natural fibres in existence. It is also quite soft, very light, highly breathable and good for moisture wicking. Moreover, the fibres have a triangular prism-like structure that reflects light at various angles to produce an optical shimmering effect.

The best print results come from acid dye ink, which will also require the printed fabric to be steamed to fix the colours and then washed several times to ensure that there’s no unfixed dye left behind.

Acid dye inks can also be used with other animal-based natural fibres, such as wool, which also work with reactive and pigment inks. Wool is typically quite bulky and holds heat quite well, making it best for warm clothing. There are different types dependent on the source animal, such as alpaca, as well as mohair or cashmere from goats. Even amongst sheep’s wool there are several variants, such as merino, which is softer and lighter, and Cotswold, which is coarser, that both come from different breeds of sheep. The quality of the wool will dictate the most suitable type of ink, such as acid for most applications involving merino wool.

Synthetic textiles

Most synthetic fibres generally create better barriers to water, which is good for water-proof clothing but also means sweat can be trapped inside the garments. They have good elasticity or stretchiness, making them very suitable for sportswear. They are mainly derived from fossil fuels and do not generally have good fire resistance.

Perhaps the most common is polyester, which is fairly light and has good breathability making it popular for sportswear. Polyester a type of polymer from the ester group but there are a number of different ways to create polyester variants. The most common is ethylene polyester or PET and there’s even a plant-based form of polyester where the ethylene comes from natural sources like sugar cane.

The best results normally come from printing to a transfer paper and then sublimating the inks to the material, so that the pigment bonds into the fibres. This produces an excellent hand-feel with good wash fastness. That said, some vendors do offer DtG printers for polyester that use a primer to hold the ink to the fibres.

There are also many blended materials that offer the feel of natural fibres with the functionality of synthetics. However, because the different fibres hold onto the pigments in different ways, you have to be careful about the percentages of the materials being blended. Poly-Cotton for example works best with at least 70 percent cotton to 30 percent polyester.

Most textile print vendors are developing pigment inks that will sit on the surface of the material and should work with many different types of fabric so that this is not an issue. However, they rely on primers to hold the ink to the surface, and softeners to improve the hand-feel of the prints. Washfastness is still an issue so that this is still a work in progress for many vendors.