Climate change continues to be an ongoing issue, many European governments are changing their laws to help lower their environmental impacts. This has resulted in an increase in electricity prices. Many printers now are looking for their equipment to be energy efficient before buying.

In April 2021, across many European countries people were very preoccupied with the ongoing Health Crisis. The European Union Parliament announced an aim to reduce carbon emissions by at least 55% by 2030. Due to these changes, there has been a necessity for equipment and machinery in every industry to be energy efficient, as energy costs will become more expensive due to the Total Cost of Ownership (TCO).

But how can printers determine which wide format printers and other machines are energy efficient? Energy efficiency is the goal to reduce the amount of energy required to provide certain amounts of products and services. But to do so, it is important to measure the facts in a fair and unbiased way.

For digital printers, there are already two ISO norms:

- ISO 21632 is intended for machines that have few energy transition periods. Which means printers with modes other than a production printing mode contribute significantly to overall energy consumption. It can be used to compare machine set-ups from best quality to the fastest high productivity mode.

- ISO 20690 is intended for multiple mode digital devices which typically work longer print runs, as stopping and starting always causes considerable energy usage. It describes a standardized method for estimating energy efficiency for any digital production printing press used for professional production.

There are other label manufacturers who promote their machinery as being energy efficient. Energy Star, Blauer Engel or RAL-UZ 122 are some who are the most widely recognized. Quite a few market-leading printer manufacturers, including Canon / Océ, Epson, HP, Konica-Minolta, Mimaki, OKI and Xerox offer printers with an Energy Star certification by US Environment Protection Agency EPA.

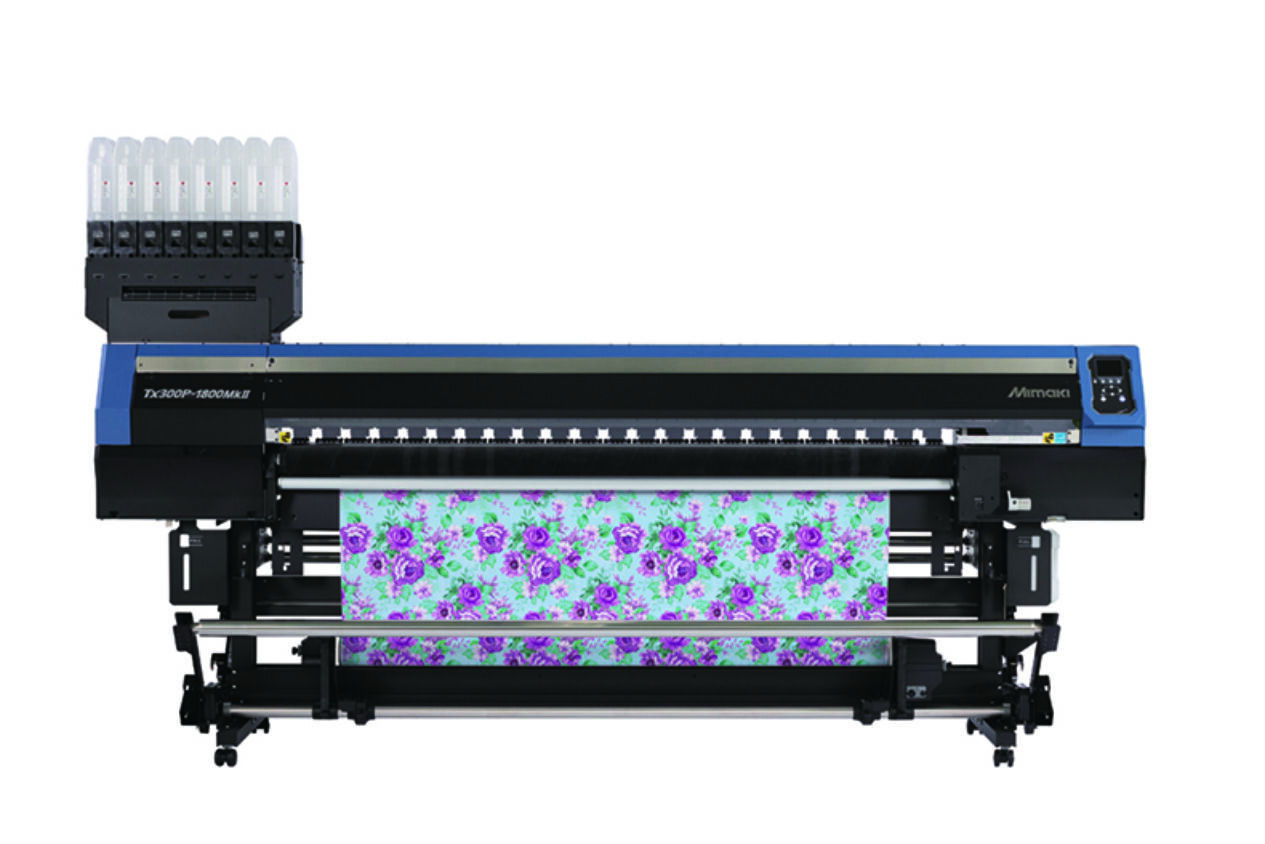

The Mimaki - Tx300P-1800 MK II is Energy Star certified.

Image credit: Mimaki.

Energy Efficiency of The Printer is Just a First Step

Digital printers are very diverse and range from small Fine Art printing devices to equipment for in-house printing departments and digital production printing all the way to (super) wide format and industrial inkjet.

Unlike most commercial analogue printing applications, many standard digital printing jobs also require a wide range of pre- and post-production processes, resulting as requiring more machinery such as dryers, calandars and laminators to create a sellable product.

Also, compared to their analogue counterparts, digital printers require very stable environmental conditions, the temperature range is usually between 18 and about 30 degrees Celsius. In most climate zones, this means a need for air condition and /or heating, which does increase the overall energy use.

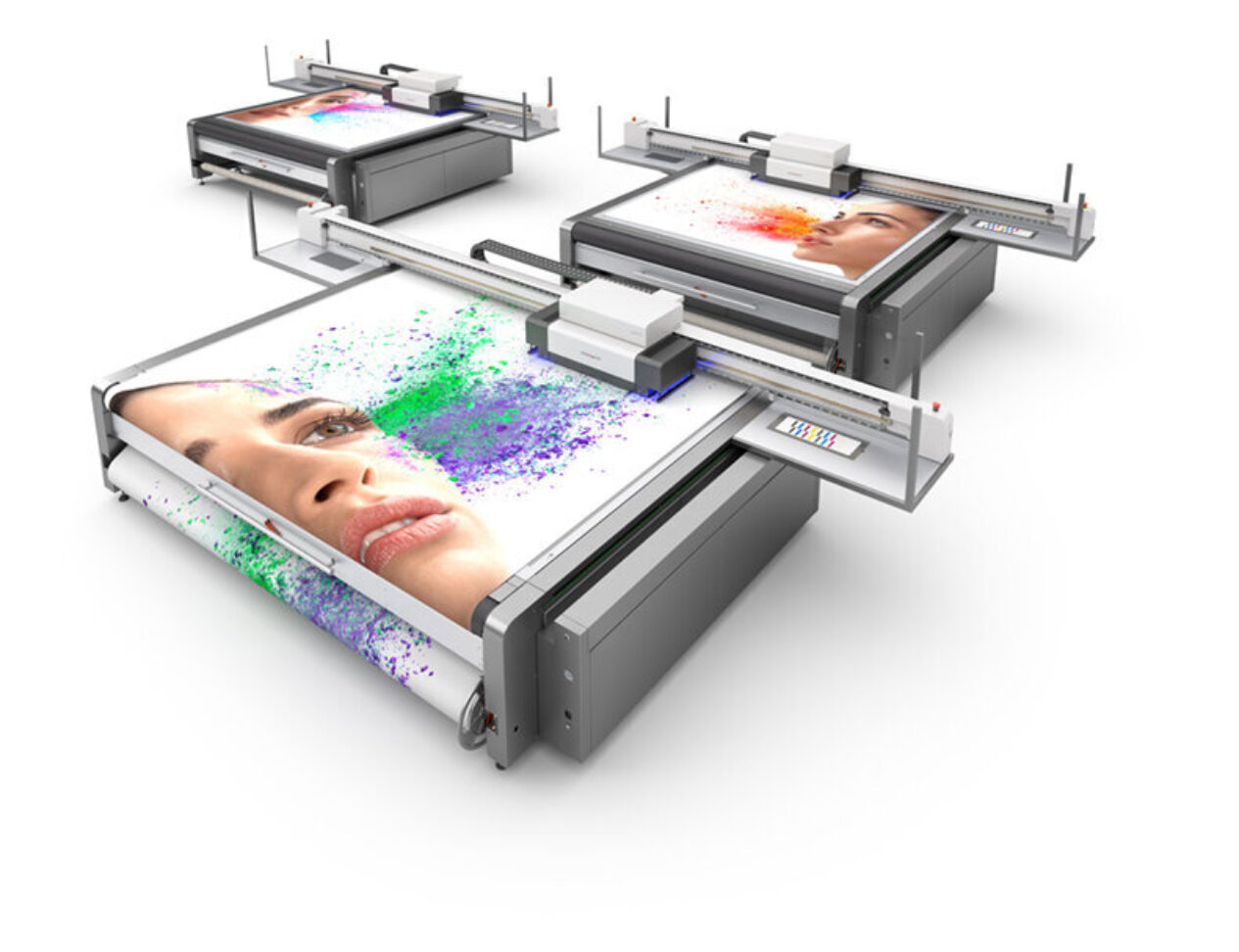

Swissqprint is the only major manufacturer to certify their range to the ISO 20690 standard

Image credit: Swissqprint

Can You Really Compare Printer Energy Efficiency Today?

So far, ISO 20690 has not been widely taken up by the industry, as Swissqprint is the only major manufacturer to certify their complete range to this standard. Their Nyala, Karibu, Oryx and Impala printers work with UV-LED technology.

Due to technical requirements, Latex and water-based inks tend to require higher levels of energy than UV-LED, due to the high amount of water used in those inks. The inks have to be dried immediately for the prints to useable.

However, there are complications in digital textile printing. The latest pigment ink technology does not require sublimation, washing or drying. Examples include Kornit Digital or EFi Reggiani, they still achieve beautiful and lasting printing results on almost any fiber, man-made or natural. Compared to traditional screen printing on textiles, the whole process is therefore much more energy efficient, requiring less water and chemicals as a bonus.

What Is a Printer to Do?

Customer demand for energy efficient printers is already quite substantial. Like many other customers, printers aim to protect the planet with their buying decision. Also, the necessity for energy efficient equipment is driven by an already substantial growth of energy cost. Many European countries already have decided to further increase energy costs even further through taxation and CO2 compensation measures in the coming years.

It seems evident that the ability to easily compare energy efficiency levels will help printers make more informed planet-friendly buying decisions. However, the ISO standards 21632 and ISO 20690 seem to have not made a big impact on the situation just yet, as the general uptake is slow.

Some of the competing energy efficiency labels are not as fine-tuned for digital production or wide format printing as ISO 21632 and ISO 20690. The Energy Star “Imaging Equipment” section covers printers, scanners and multifunction devices. On its buying guidance pages the Energy Star’s main focus is on sleep mode settings, which is clearly more important for office than for production equipment.

This situation makes it difficult for printers to really compare energy efficiency between printers. It is important to consider the whole production process and not single out printing equipment only. Printers still need to push suppliers to do more to enable them to compare energy efficiency levels as part of a planet friendly buying decision.