Nessan Cleary shares the benefits and challenges for print businesses using automation in their business processes and production workflows.

There are a lot of different processes involved in producing large format graphics, from the sales through to production as well as managing the business overall. Automating as many of these steps as possible should lead to greater efficiency and less errors. However, automating discreet elements will only get you so far; the real benefit lies in grouping whole processes together to significantly cut down on the need for manual intervention.

Naturally, such automation will come at a cost so the trick is to plan the different areas together to see if the overall benefit is worth the outlay or if there are small changes that can have disproportionate reward. That said, many printshops may feel that they simply don’t have a choice because of the continuing demands from customers to turn jobs around faster and with lower costs. Here, automation is really the only way to reduce human touchpoints and push jobs from one process to the next.

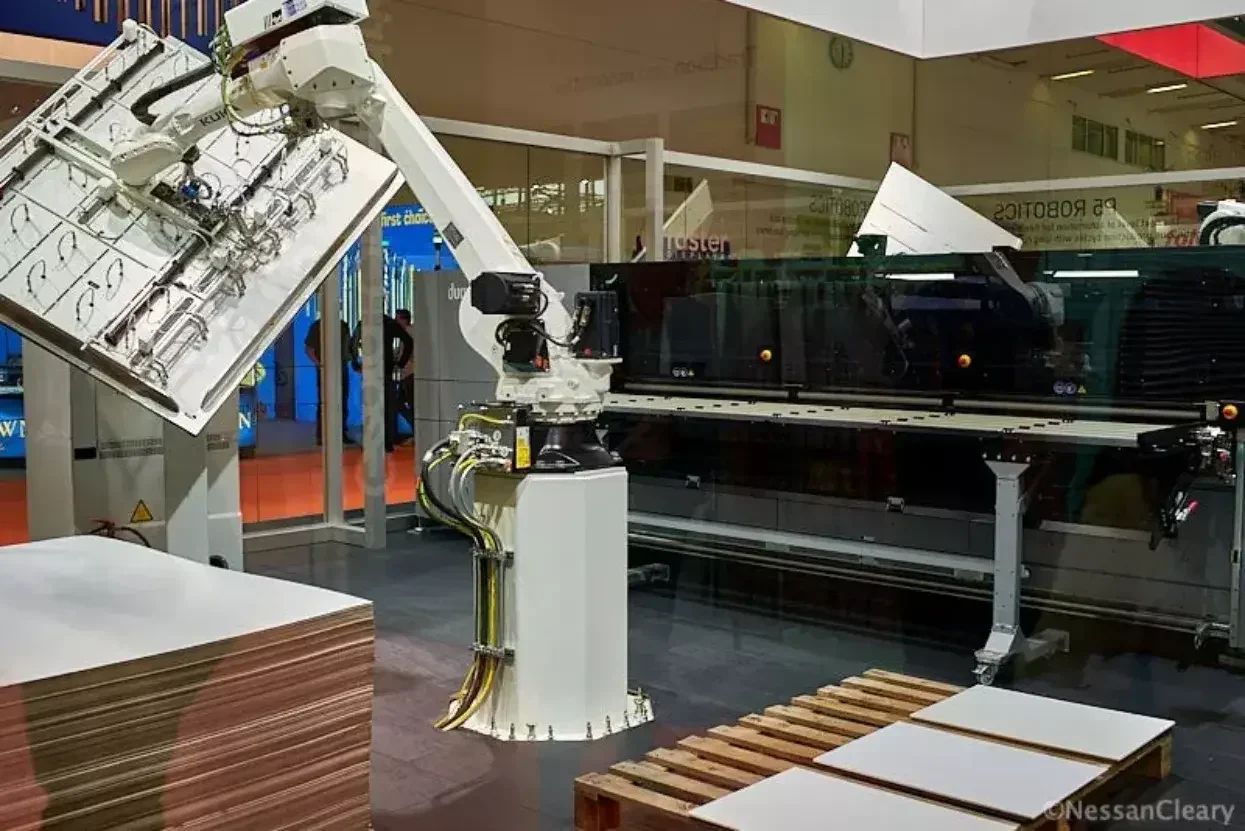

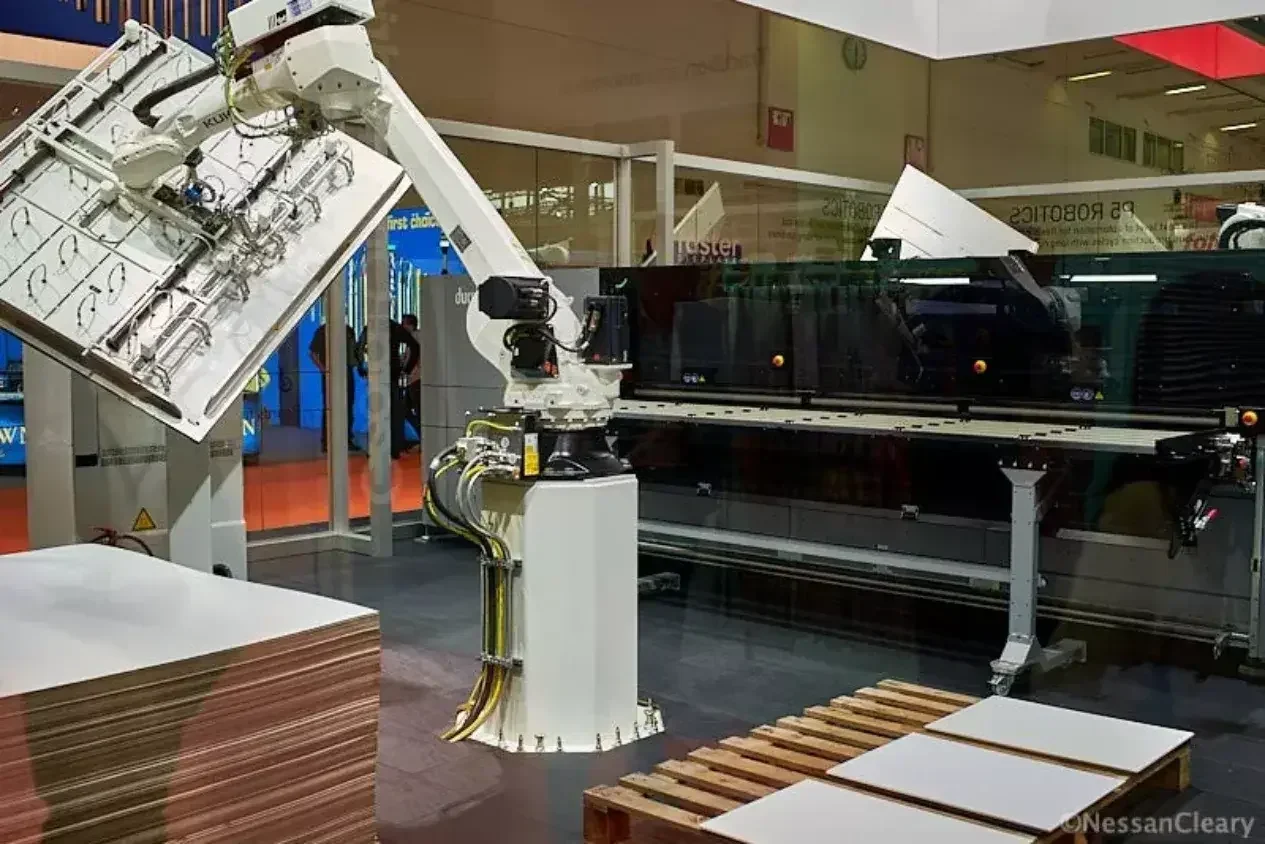

Durst showed this P5 Robotic loading and unloading system at last year’s Fespa show.

Image Credit: Nessan Cleary.

The argument for or against automation will also depend on labour issues, as automation can reduce the amount of staff required but may cost more than the staff you’re replacing. Automation can also be used to reduced the amount of skill required for certain processes, which can also help to cut the wage bill with less expensive operators. More importantly, reducing the reliance on staff with particular skill sets can help overcome the lack of such skills in certain regions. But rather than using automation as an excuse to cut the workforce, it could also be used to expand the business – perhaps by adding an extra shift – without needing to increase the labour costs.

Most automation can be split across two main areas – business process and production workflow – but the most efficient approach is to combine both of these to ensure that you both complete each job and make a profit on it.

In the past people might have thought of the production workflow as simply being the RIP directing files to the printer. But its more effective to see this as the entire production process, from files coming in, through printing and into finishing. This usually means combining several systems, such as web-to-print and RIP software but there are several specific areas that can cause problems.

The biggest single issue for most printshops is the poor quality of files from customers, who often have little idea of what constitutes print-ready and instead just hope that the printshop can somehow ‘sort’ it all out. A decent flight checking program can catch and fix most problems. But you will have to set a threshold to determine at which point you need a human assessment of a file. It’s also best to have a clear terms and conditions policy and make sure that customers understand their risks and responsibilities.

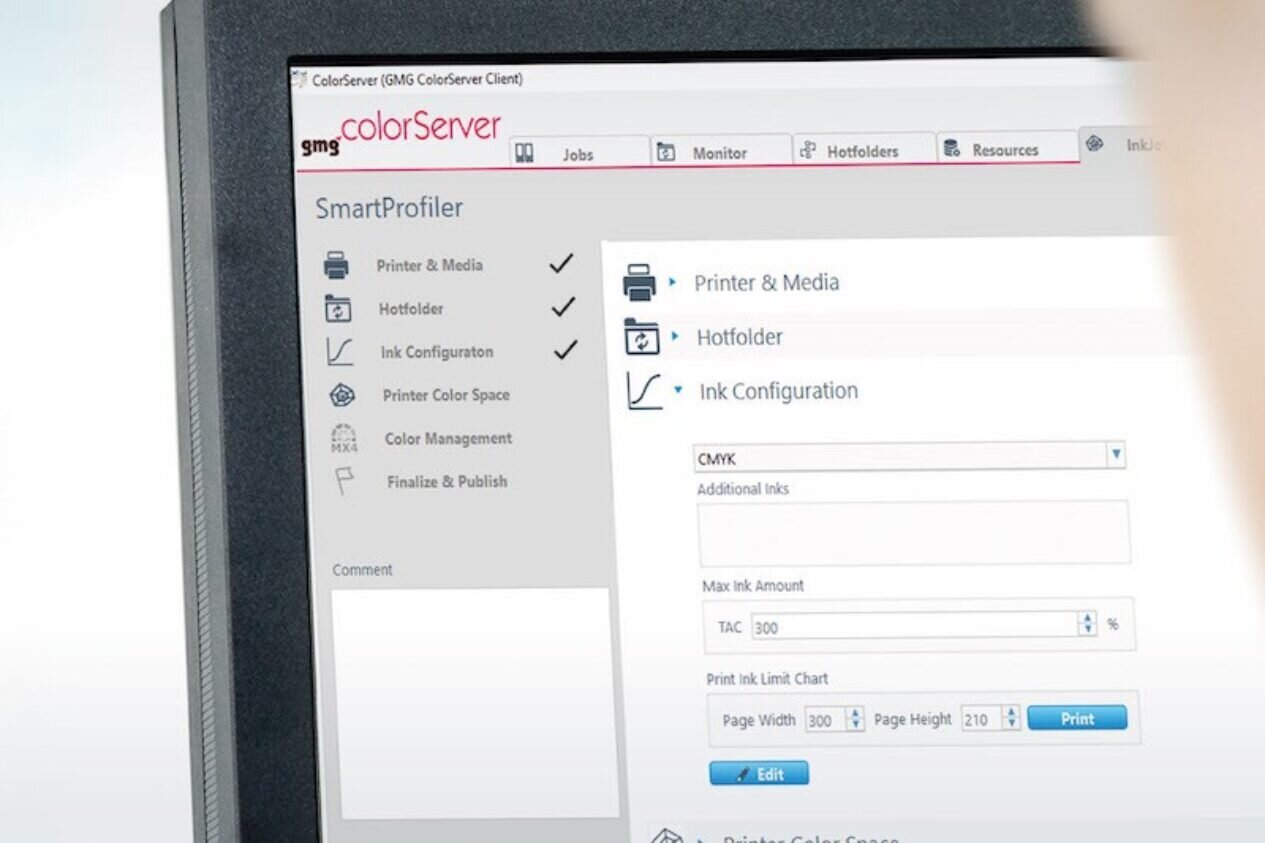

GMG’s ColorServer can be used to automate many colour management tasks across a fleet of wide format printers.

Image Credit: GMG.

Another area to think about is load balancing, ensuring that the right jobs are routed through to the most appropriate printer. That might mean switching printers at the last minute, so you will also want to ensure that the printer profile, complete with media management and any nesting or ganging, as well as colour management, can all be updated.

Another area that should be automated is the imposition planning, with jobs ganged together or different shapes nested together to optimise the use of media. It’s relatively straightforward to do this for one printer since most RIPs include this feature, but its harder to do it across a fleet of printers without a dedicated imposition system.

Most large format machines now include some level of remote monitoring, which allows individual operators to run several machines at once. Those operators should also be able to check the ink levels and to plan any head cleaning or other tasks throughout a shift so that only one machine is stopped at a time.

Another area ripe for automation is loading and unloading substrates from printers and cutting tables. As this equipment becomes faster, so the need to move the boards around risks becoming a bottleneck. There’s also the risk that this physical work becomes a health and safety issue due to the size and weight of such materials.

Most vendors selling fast flatbed or hybrid printers also offer various degrees of automated loading and unloading but such systems usually only deal with moving the materials on and off one particular machine. It’s more efficient to consider how you’re going to move the boards through the production process, which should also include getting them from the printer to any post processing such as a cutting table. That could include a robotic arm that’s placed to reach between the back of the printer and the cutting table. Or it might be easier to have a conveyor system or an autonomous guided vehicle move palettes from one autoloader to another.

Another area that’s often overlooked is the back office tasks, such as managing inventory and the overall admin including staff wages and customer invoices. All of these tasks can easily be automated through software. A Management Information System or MIS can bring all of these tasks together. More importantly, an MIS can also be used to oversee the production workflow, pushing each job through one production stage to the next and building an invoice along the way.

One caveat to be aware of is that automation works best with standardisation. If you can create a list of standard products, such as banners or pop-up displays, then it will be much easier to automatically move those jobs through production. But many large format firms cater to bespoke jobs that require a degree of creativity to design and execute, and this sort of thing will be hard to automate. Then again, these sort of jobs really help print shops to differentiate themselves and add value to the overall offering.

Finally, it’s worth considering the things that put many people off investing in automation. Often this comes down to cost and worries over seeing a return on this investment. But many firms also worry about the upheaval to the business caused by introducing new systems, which can be partly mitigated by breaking this investment down into sections and completing them one at a time. That said, there are numerous surveys in recent years that indicate that most printshops know that ultimately they have to introduce more automation to speed up their production if they are to survive.