Print varnishing and 2.5D structures are popular with print buyers. Sonja Angerer discusses how these structures are produced with inkjet, what the applications are and what market printers can venture into?

There are numerous uses for textured surfaces: whether gloss lacquer or relief, people are often intrigued by haptic effects. For a long time, special surfaces could not be produced using special paints or screen printing. Today, UV-curable inkjet inks have taken the possibilities of designing printed surfaces to a new level.

This article will cover the following:

- how print varnishing and 2.5D printing with inkjet inks works

- what applications are possible?

- what are the advantages and disadvantages of inkjet print varnishing and 2.5D printing?

- the market opportunities for special surfaces for printers

How does Inkjet print varnishing work?

For print varnishing 2.5D printing, you need a digital printer with an extended ink set. In 2013, Roland DG launched the first models of structured printing. Today, most manufacturers offer inkjet models that can also print white inks or clear fluids.

Printing varnish can be applied completely or partially using the inkjet process. With partial print varnishing, the areas to be varnished are created as a spot colour in the design or in the RIP. Generally, you can also choose different levels of matt or gloss finishes. This is because these can be easily altered by the lamp setting during curing.

2.5D prints are mostly printed on rigid materials. From January 2024, Mimaki will also offer the UCJV330-160, a roll-to-roll only printer that can print reliefs for the first time.

Image Credit: Mimaki

2.5D printing with UV ink

Compared to printing with water-based or eco-solvent ink, the layer thickness of UV inkjet printing is considerably higher. Even with standard prints, elevations are easily seen. Therefore, if many layers of UV-curable inkjet ink are applied on top of each other, the outcome is a relief. Raised areas can consist of white ink, clear varnish ink, and coloured ink, as well as a combination of all three.

How high the ink layers can be stacked, depends on the clearance height of the printer, to prevent the print head to be damaged in the process. About 10 to 20 layers are common.

Many manufacturers who offer inkjet printers for textured surfaces, such as Mimaki, swissQprint or Durst, have created options in their RIPs to use or adapt libraries of structures. In some cases, there is special software for textured surfaces such as Canon’s PRISMA elevate XL. Some universal RIPs, such as Colorgate Productionserver, support 2.5D printing with the additional options to create custom 2.5D structures by recording height and gloss information with a 3D scanner and storing them as bitmaps along with the motif.

Textured inkjet surfaces are typically printed on rigid boards. This is because if the carrier medium is bent too much, there is a risk that the relief will come off. At the beginning of 2024, Mimaki launched the UCJV330-160 model, their first roll-only printer that can print structures.

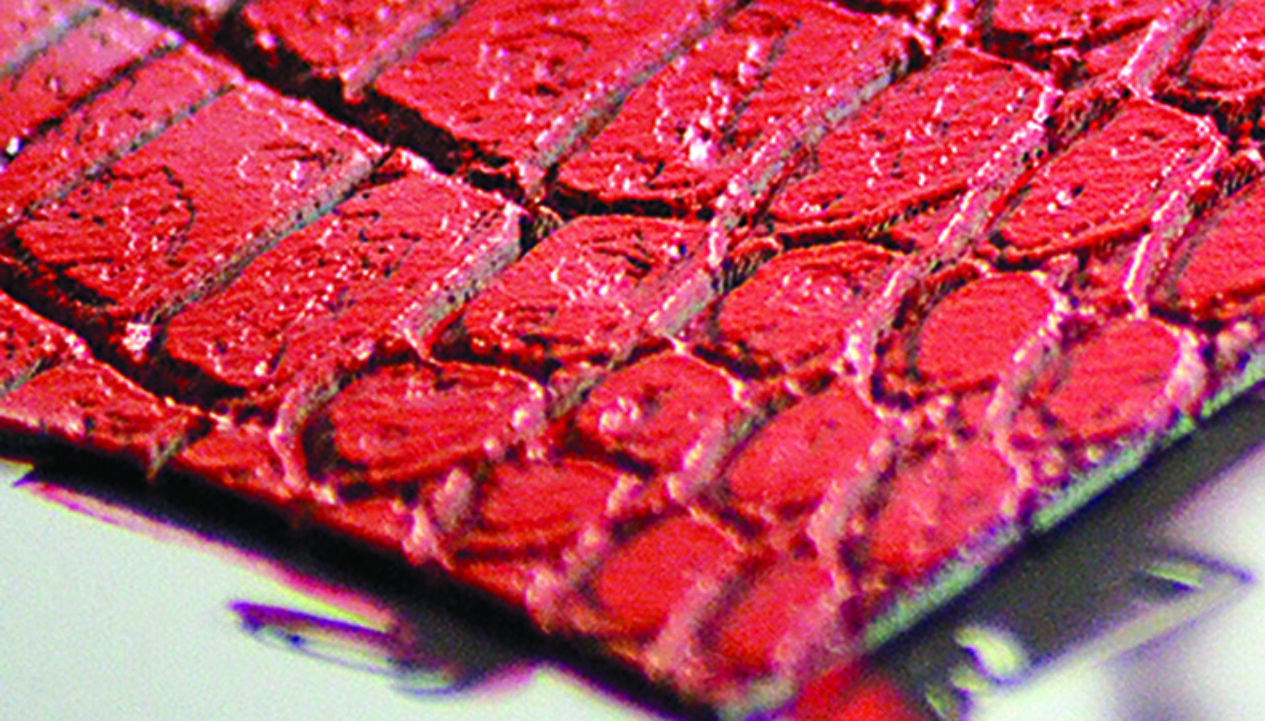

Art reproductions with relief print look very natural.

Image Credit: Mimaki

Printing varnishing and 2.5D printing: areas of application

Textured surfaces from inkjet printers have a wide range of applications. They are popular in art, for example for reproductions of paintings with pasty colours. You can also create stand-alone artworks playing with 2.5D structures. Further niches for textured surfaces arise in interior decoration, for example in the reproduction of wood grain.

In addition, structured surfaces are sometimes used for POS applications or shop window decoration, but also for high-quality mailings.

In the swissQprint Creative Challenge, Signaletik Diffusion took 4th place with "Le couteau swissQprint", a replica of a Swiss Army knife. Relief elements give each tool a unique look.

Image Credit: swissQprint

Braille with inkjet

With 2.5D technology, also it is possible to print raised lettering, pictograms, directional arrows, and Braille letters. Recently, a large market has developed especially in the USA as the Americans with Disabilities Act (ADA) requires assistance for people with physical or mental disabilities to be available in public buildings as well as in most shops and offices.

As a result, more and more signage must be equipped with Braille lettering. The conventional production of signs with Braille is very complex. This is because the elevations must be at least 0.4 millimetres with a letter height of 6 to 7 mm so that they can be easily felt. Depending on the material, this can be achieved by punching or embossing, but also by inserting tiny beads into milled holes.

2.5D printing with inkjet printers is ideally suited to simplify the production of Braille signs. That’s why Mutoh has integrated Braille printing capabilities into its VerteLith RIP. However, it is also possible to create Braille characters for printing with inkjet in external software such as CADlink Digital Factory UV Edition DesignPro.

It should be noted that the Braille system is used in many countries around the world. However, it is not universal, as some characters are adapted to the national language. There are also national differences in the implementation of signage. For example, in Germany, DIN 32976 holds all requirements and dimensions.

In addition to Braille, it is also possible to produce profile letters and tactile models for blind and visually impaired people with the help of 2.5D inkjet printing.

Advantages and Disadvantages of Printing Varnishing and 2.5D Printing with Inkjet

Partial print varnishes and textured surfaces can be achieved easily and cost-effectively with inkjet compared to conventional processes. This is because there is no need to create templates. As a result, small series and one-off pieces can be produced cheaply.

However, for full-surface print varnishing, varnishing tables or screen-printing processes are almost always more cost-effective, as the ink consumption during varnishing and 2.5D printing with inkjet ink is quite high. Also, productivity tends to be significantly lower than with 2D printing.

For tactile applications in very busy places, it should also be considered that plastic is exposed to greater wear and tear than metal. This can result in a shorter life of the signage, which must be considered for warranty.

Market Opportunities for PSPs in 2.5D Printing

Textured surfaces and 2.5D artwork and reproductions offer good opportunities for printers ready to specialise in these segments, a move likely to be particularly successful for companies that already have a customer base in art or regularly work for museums.

The 4 x 3 m reproduction of Johannes Vermeer's "Girl with a Pearl Earring" was printed on a Canon Arizona with haptic effects for the Mauritshuis Museum using the PRISMAelevate XL software.

Image Credit: Canon.

The demand for signage for visually impaired people is also expected to increase significantly in Europe in the near future. This is because an ageing population is increasingly dependent on aids for orientation. However, it must be considered that the requirements and standards may differ significantly across jurisdictions.

For the application of 2.5D printing, it will also be necessary to build up very special capabilities in the company. This includes, for example, the creation of three-dimensional structures, or some knowledge of Braille. As a result, additional investments in software and trainings are required in addition to the hardware. However, this also means that competition is unlikely to be as strong as with standard applications. After all, building up this specialist knowledge takes some time.

To discover the latest content that covers a wide range of sectors including print finishing, fine art and screen printing sign up for FESPA’s free monthly newsletter FESPA World available in English, Spanish and German.