Rob Fletcher looks at 2 key trends and finds out more about how working with sustainable materials will help you capitalise on rising demand for environmentally friendly packaging.

While we are all aware of the noise being made around sustainability, what is important for print service providers (PSPs) is applying this to the type of work they produce or markets they intend to move into.

After all, you can put plenty of effort into becoming a more sustainable business, and rightly so as we all play our part in protecting the planet, but if you are able to use this enhanced image to win new work, then you are looking at something of a double win.

One wide-ranging market where sustainability plays a major role is packaging. The demand for paper-based packaging has rocketed in recent years as brands and retailers look to work with materials than can be easily recycled and have less impact on the environment. If you can offer this, then you are in with a chance of securing some of this work.

Here, FESPA.com speaks with suppliers in-the-know to find out about their latest packaging materials and the key, environmental advantages these offer to PSPs and their customers.

Increasing pressure from consumers

First up, Antalis offers a range of packaging solutions to the market. John Garner, head of sustainability, innovation and design at Antalis, said one of its customers is looking for a more sustainable solution, and it is up to the company to respond.

“There’s a huge amount of pressure from consumers to reduce the amount of waste that they are receiving,” Garner said. “It’s a message that businesses just can’t ignore; Antalis has data from surveys we have undertaken that suggests purchasing decisions are driven by sustainability.

Consumers are placing more emphasis on sustainable packaging.

“If we look back 10 years, sustainability carried around a 10% weighting in decision making. It’s over 25% now. The continuing growth in e-commerce has undoubtably exposed more people to packaging. Let’s not forget that all packaging at the end of life is someone’s rubbish! Therefore, it’s incumbent on the whole industry and consumers to demand more sustainable solutions.”

Garner went on to say that Antalis is constantly working on new substrates and materials, adding that it gives a guarantee to all customers that it will always offer a more sustainable solution than the one they are using now.

In addition, Garner issues a warning to the market in terms of greenwashing, saying that Antalis can help customer identify truly sustainable solutions for packaging.

“There’s some real numbers and science around how and why solutions impact on the environment – Antalis can help navigate through this,” he said.

Significant steps towards a sustainable future

Up next is Sulapac, a specialist supplier of plastic alternative solutions, including materials suitable for use in packaging production. Co-founder and chief executive Suvi Haimi said based on Sulapac’s experience, sustainability is very much at the core of packaging discussions. However, Haimi added, the ambition level and the specific sustainability targets vary greatly.

“Some players are content if they manage to reduce their material usage just a tiny bit, whereas others aim to replace all oil-based plastic in their packaging with more sustainable options to reduce their carbon footprint and tackle plastic pollution,” Haimi said.

“Price and functionality still play an important role too. The good news is that today there are sustainable, bio-based material alternatives available in the market that can fully compete with conventional plastics, allowing brands to maintain their strict quality standards while taking significant steps towards a more sustainable future.”

Haimi goes on to draw attention to the business’s key development of Sulapac, a bio-based material with a low carbon footprint that incorporates waste-based feedstock and side streams and leaves no permanent microplastics or toxic substances behind yet meets the quality standards of the world’s most prestigious luxury brands. Chanel is one user and has been working with the company since 2018.

“Our materials have many advantages over conventional plastic: by replacing conventional plastic with Sulapac materials, companies can eliminate microplastic pollution, reduce their carbon footprint, and cut dependency on oil,” Haimi said.

“When talking about sustainability trends in packaging, recycled plastic is clearly something that many see as the ultimate solution. Unfortunately, that’s a false belief, for three reasons: In mechanical recycling you always need to add virgin material to the process, whereas the chemical recycling of conventional plastic requires high temperatures and hazardous chemicals. Finally, recycled plastic does not solve the microplastic pollution problem.”

Antalis says demand for sustainable packaging is increasing across its customer base.

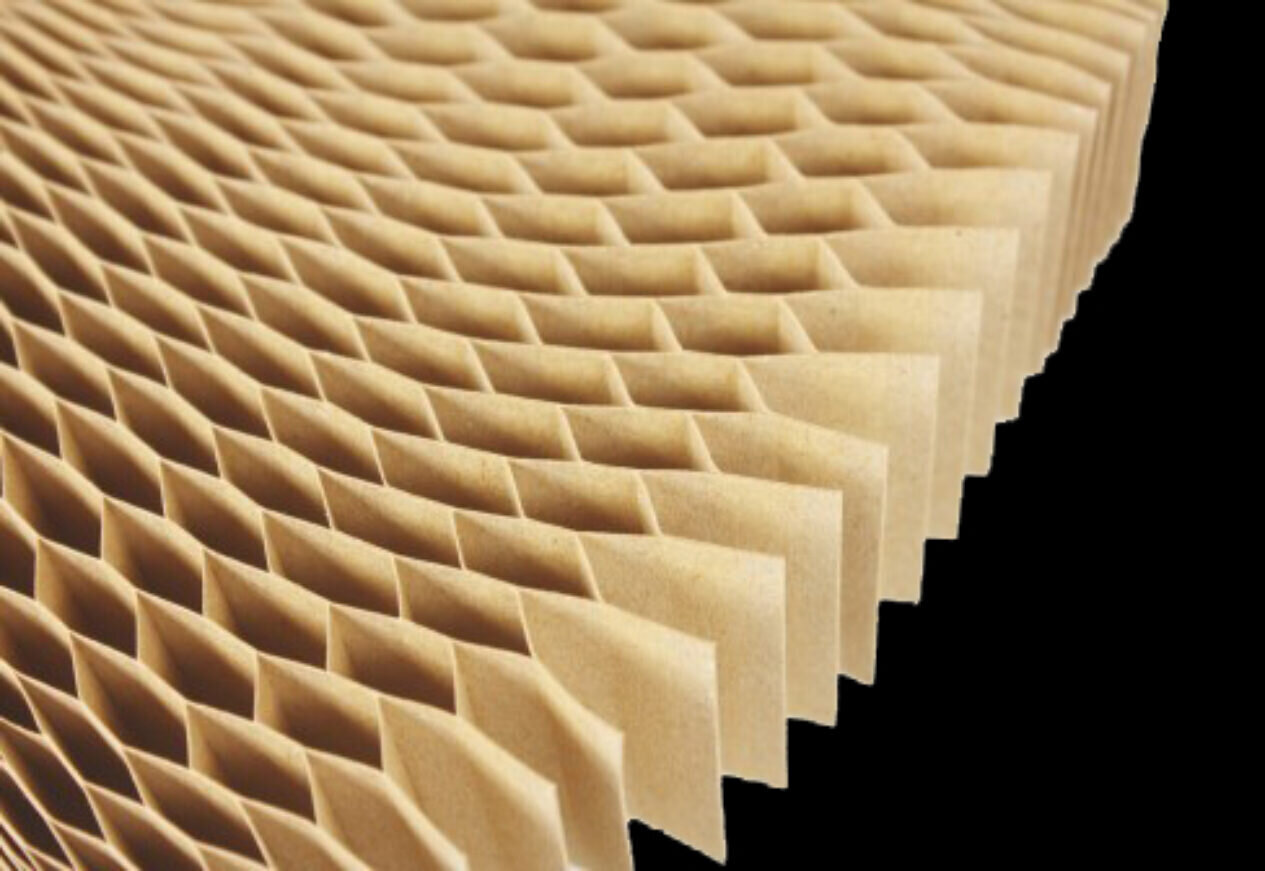

Pictured: a honeycomb material from Antalis.

The key point here, Haimi stressed, is that Sulapac and similar materials can be effectively chemically recycled in low temperatures with excellent yields and without microplastic emissions. The resulting material can then be used to create new food contact compliant products.

“To fix the problem of plastic pollution, which is largely tied to packaging waste, the only possible way is to move away from fossil-based plastics,” Haimi said. “It is clear that this kind of transition does not happen overnight, but with proper legislative support, and by increasing awareness among all stakeholders, we can accelerate the shift to biobased biodegradable materials and packaging that can be effectively recycled. Join us in building an endless loop of good.”

Kitting up for sustainability

While the focus here has very much been on materials, choice of machinery can also play a major role in packaging production capabilities. Northern Ireland-based Biopax recently took on a second Speedmaster XL 106 from Heidelberg to support its production of environmentally friendly packaging.

Biopax primarily works in the UK and Ireland, preparing packaging solutions such as printed cartons, paper wraps and labels for the food, beverage and non-food sectors. As part of its strategic growth plans, Biopax has begun exports into European markets and intends to set up production facilities for sustainable packaging in Europe, India and the People’s Republic of China. This led it to the new investment.

“Having two printing presses with equal capability in terms of high-quality print, optimum output and reduced set-up / down-time will strengthen our contingency in the most complex part of our manufacturing process”, Biopax sales and marketing director Liam O’Connor said.

Sulapac counts Chanel as just one of the luxury brands it works with on sustainable packaging

Picture credit: Sulapac

Declan Martin, account manager at Heidelberg, added: “The Speedmaster XL 106 has multiple standout benefits. It is highly energy efficient, delivers impeccable print quality, and great performance. We have had a strong relationship with Biopax, and we’re delighted they have chosen Heidelberg once again with its second Speedmaster XL 106 with Push-to-Stop technology.”

This purchase perhaps sums up this market: constant evolution. While PSPs face new and tougher challenges in terms of delivering sustainable packaging, innovative materials are coming to market all the time, allowing them to overcome these hurdles and deliver high-quality, planet friendly packaging to customers across a wide range of markets.