Still a hugely popular method for print companies around the world, Rob Fletcher takes a look at the screen printing market, speaking with manufacturers about their latest developments and considering what we can expect in terms of the sector’s future.

A tried, tested and widely respected printing methodology, screen print is a hugely popular way of printing certain products. From posters and canvases to fabrics and textiles, print service providers (PSPs) around the world count on screen print to deliver all kinds of colourful and creative pieces to customers across a range of markets.

To ensure PSPs can continue to respond to the ever-changing demands of their customers and deliver high-quality prints, manufacturers are constantly working to develop and bring to market new solutions that allow printers to stretch the boundaries of screen print – with examples of this apparent at the 2024 FESPA Global Print Expo.

Here, FESPA.com catches up with several manufacturers in the screen print market, learning more about their latest and most popular machines, as well as how these devices can help users access the most profitable work in various markets.

Adding a personal touch

First up to offer advice and guidance is Roq International, which specialises in the production silkscreen and digital print, folding and packaging machines for textile and other industries. Renato Freitas, who oversees digital marketing at Roq, said one of the stand-out trends PSPs should be aware of when it comes to screen printing is personalisation.

Of course, given the reach of screen printing and the areas where it is most commonly used, the opportunities of personalisation are widespread and plentiful. These could be anything from custom t-shirts and other garments to specially printed canvases that have become a hugely popular gifting option at Christmas and other celebratory occasions.

But why opt for screen printing over other technologies and methods? Freitas offers some thoughts on the matter: “When it comes to working with screen printing machines, the most important features are reliability, speed, productivity and print quality. All of this adds up to allow you to offer excellent customer service across all types of products.”

Leading on from this, Freitas picks out the latest offering from Roq in the form of the Roq E, an automatic screen-printing press that offers users a quieter, yet still highly effective, solution. The press has a top speed of up to 900 prints per hour and is billed by Roq as being easy to operate.

“The Roq E rethinks and enhances automatic screen printing, offering the first-of-its-kind self-contained functionality that eliminates the need for third-party air supply, ensuring the iconic Roq-quality prints You’re known for are produced without external dependencies,” Roq said.

“The Roq E’s sleek design houses an ultra-quiet built-in air supply, ensuring a premium, noise-free experience for Your star customers. Offering eight or 10 stations with up to eight colours and low-profile platen arms, it redefines versatility, including effortless sleeve printing.”

Also from Roq is the Roq Next, which Freitas said is its most popular screen print solution. The device offers a 20% increase in productivity compared to older machine and features XL print models, an individual print head lifting system and chain-driven servo rotation system.

Other key features include simple setup, such as print-from-screen functionality for quick strike offs, as well as faster indexing for cycles up 1,200 pieces per hour.

Cost-effective options

Also weighing in is Paul Zingone, marketing coordinator at Vastex International, another manufacturer of screen printing equipment. Addressing the current market and stand-out trends, Zingone said Vastex has witnessed growth with customers that started out with direct-to-garment that are now looking to add screen printing capabilities to widen their service offering.

“They need a quicker, more cost-effective option for one- and two-colour jobs at higher quantities; screen print offers this” Zingone said.

As to what companies should be looking for when investing in screen printing equipment to best take advantage of demand in the market, Zingone said it a good starting point is to look at the warranty of the machine. This, he explained, will tell users a lot about the build quality or a piece of equipment.

“If you see a 15- or 25-year warranty, you know that the machine is built to last,” Zingone said. “Also, look for features that will help you speed up setup or production. For example, anti-backlash micro registration on a press will greatly decrease your setup time and have you printing sooner. On a conveyor dryer, digital temperature controls, adjustable belt speed and heater height adjustment allow you to dial in your setting for optimal ink curing.”

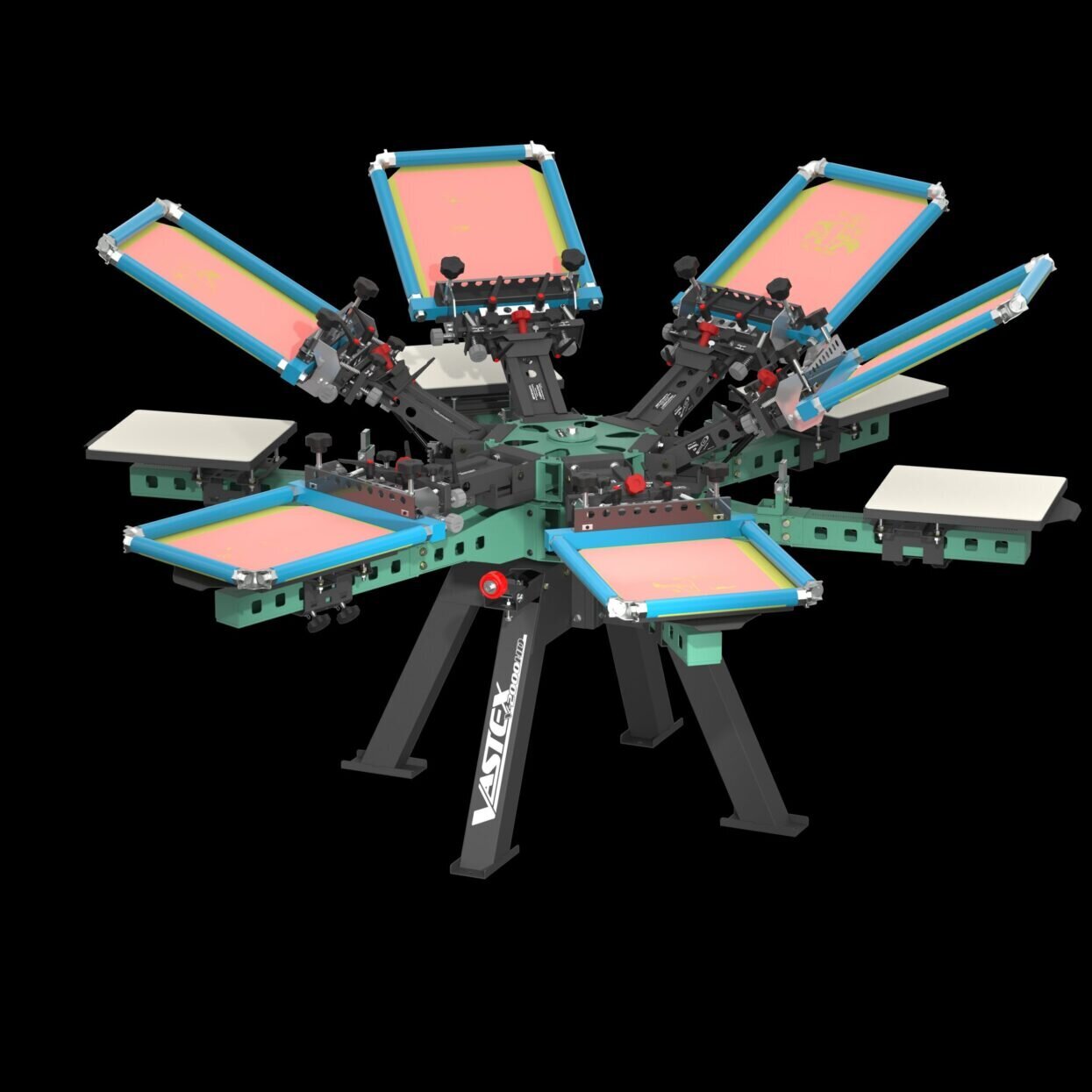

As to how Vastex can support PSPs with their move into screen printing or efforts to bolster their current offering, Zingone highlights several machines. First is the V-2000HD, which, he said, due to its durability, and ability to be expanded in the future to add more print heads and stations, is the most popular screen printing press available from Vastex.

Another sought-after solution from Vastex is LittleRed D Series dryers. These machines can cure not only screen printing inks, but can also be used for direct-to-garment and direct-to-film. As for new solutions, Vastex recently announced the launch of its PTF-100 Powder Application Shaker, which Zingone bills as a “safe and clean option” for applying powder to plastisol and direct-to-film transfers.

“Most shops are expanding, or plan to expand, beyond screen printing alone,” Zingone said.

Market growth

A final contribution comes from Sandra Woerle, who oversees marketing at SignTronic & Grünig-Interscreen. Woerle says despite once considered a dying process, screen print is proving otherwise, with the market enjoying steady growth.

For those seeking to invest, Woerle offers some words of advice as to what to look out for in screen printing machines. First and foremost, she highlights the importance of the machine providing high precision and consistent results to ensure high-quality prints.

Then there is the issue of durability and reliability, with Woerle saying machines should be built to lost, while buyers should also look for user-friendly interfaces and designs that simplify operation and maintenance, thus reducing downtime and training requirements.

“Also important is versatility, with quality equipment able to adapt to different print needs, allowing for various materials and designs,” Woerle said. “In addition to this are high-speed production capabilities, without compromising quality can significantly enhance productivity, as well as reliable customer support and easy access to parts and service can ensure long-term performance and minimise disruptions.

“By focusing on these attributes, print companies can invest in equipment that will meet their current needs and support future growth.”

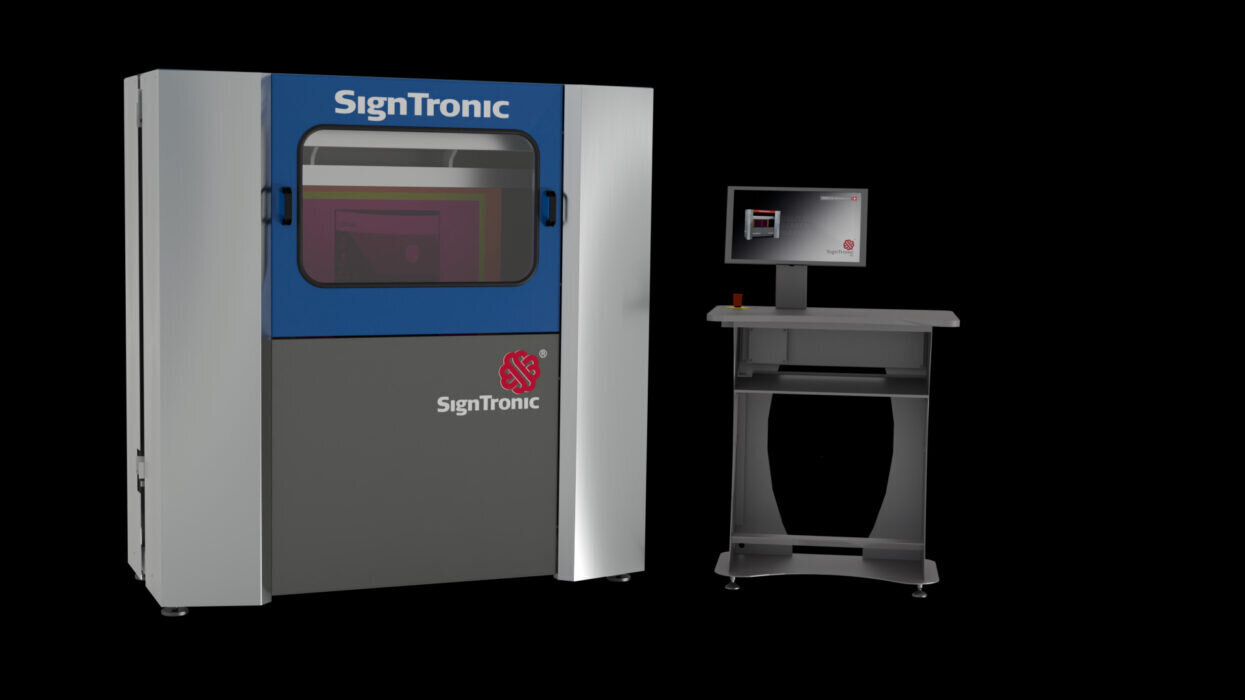

As to how SignTronic & Grünig-Interscreen, Woerle said that as a manufacturer of computer-to-screen (CTS) direct exposing systems, it can cater to all requests and market segments. She said the trend is moving to automation and standardisation with the aim of simplifying the screen making process.

With this in mind, SignTronic & Grünig-Interscreen will soon launch the new STM-TEC_XS, its smallest in-line capable CtS unit featuring LED_Q4 technology. Woerle said the solution is highly customisable due to its modular design, developed in collaboration with Grünig-Interscreen.

By having various types of technology in place, this allows you to offer a much wider range of services to customers and access work in all manner of markets. Those not running screen print machines are encouraged to consider doing so to support growth and diversification plans.

To discover the latest content that covers a wide range of sectors including screen printing and inks sign up for FESPA’s free monthly newsletter FESPA World available in English, Spanish and German.