Graeme Richardson-Locke visits the north of England and tours 3 different printing businesses including Route 1 Print, Team Impression and RMC Digital.

Last week I travelled with a couple of my FESPA colleagues to the north of England to tour three different successful printing businesses. It was very interesting visiting them in close succession as each had a clear route to market and a strong commercial offering.

The first stop was near Rotherham, where we were warmly welcomed by Mark Young, Mark Head of Route 1 Print who are a well-known, and fast-growing web to print business.

As you’re welcomed into Bluetree Group, their values are evidently portrayed.

As an existing customer, I understand only too well where they score highly in the market. If you’re able to choose from a pre-defined and far from limited menu, you’ll get to enjoy swift service and quality products. Whilst FESPA’s print procurement needs can’t all be met in this manner, there are many opportunities for us to reduce costs over a traditional model that supports increased budget for those ‘need to impress’ projects.

Mark introduced us to the various departments and key elements of the business culture. One of the values that I found curious was, ‘23:17 Teamwork’. It followed an explanation that I appreciated which is that the fastest job processed from confirmation to delivery is 23 mins and 17 seconds. A testament to the combined talents that have created automated workflows that result in this level of responsiveness. I was also impressed to learn that since achieving Living Wage accredited company status, they’ve achieved a four-fold increase in applicants for employment. This has led to hiring better candidates who start with the promise of earning 10% above the National living wage, being offered BUPA healthcare and ongoing personal development through training. In fact, Mark is a great example of this culture, he joined the business in design as a graduate graphic designer. He clearly worked hard before managing the Route 1 Print reprographics department before being promoted to his current position heading up Route 1 Print, which is the brand serving their business customers. They also meet the market through the Instantprint brand which targets end users in small business.

Mark Young of Route 1 Print beside Alina Lazar, FESPA Events Executive and Kelley-Ann Young Kong FESPA Senior Online Marketing Executive en route through Instantprint.

As we were guided through the artwork section, where each file is pre-flighted and inspected by a busy team I was surprised by the number of people in the coding and workflow area. They have developed robust workflow streams where colour management to ISO 12647-2 is embedded into the framework. Mark stated that the ratio of employees across the functions of the company is around 40% pre-production and 60% production, this is due to the increased demand for programming in achieving such high levels of automation. With it’s web to print platform well honed and developed in house as opposed to subscribing to a cloud-based subscription host, the smoothness of customer experience is impressive. They’ve achieved ten second proofing back to customers and lead-times of just a few days for pretty complex booklets and magazine formats. I believe they achieved their fastest job turnaround in their plant of business cards from sign off to despatch in only 23 minutes!

It is impressive when you consider that the business that once faced serious competition in the POS market as Bluetree Design & Print has now transformed into an online only business who are notching up impressive growth year on year. The business has been featured in The Sunday Times Fast Track 100 over two consecutive years.

We all know how our expectations as consumers in our private lives have sharpened, next day delivery is the new normal and anything less tends to require good reason to buy in.

Taking a walk through production revealed a host of kit, perfecting Heidelberg offset presses, Fujifilm Jetpress, Screen Truepress Jet, Xerox iGens, HP Indigo, HP FB11000 UV, Scodix and all the finishing plant that goes to create a well-considered armoury, where every press earns its keep.

Screen Truepress Jet, continuous inkjet.

Equally impressive was that each department displayed standard operating procedures and performance metrics for all to see. As you’d expect this is underpinned with ISO 9001, ISO 14001 and FSC registration. You can see that, Bluetree Group engages tirelessly in reinforcing a very robust production site and isn’t ‘winging it’ anywhere. With delivery of their first Landa nanographic press just a little way ahead it’ll be interesting to see what new offerings will be added to the menu.

A view across Bluetree Group’s facilities.

Following on from this interesting visit was our visit to TEAM Impression in Leeds, a similarly well equipped but different printing business whose stocking trade is non-standard bespoke printed products. Here we were looked after by Peter Crowson, Managing Director and Simon Bucktrout, Sales Director and as always by Dale Inwood their Business Development Manager.

All three are passionate about maximising the creative expression of print and in providing solutions that are tailored to customers needs. With an impressive client list of large brands, they print everything from business cards and flyers to, from my perspective much more interesting, product lines like paper over board presentation packaging and luxury case bound books. Utilising offset litho both standard and UV curing, HP indigo digital, wide format, screen print and foiling for print projects, this in-house battery supports their aim to offer everything in house.

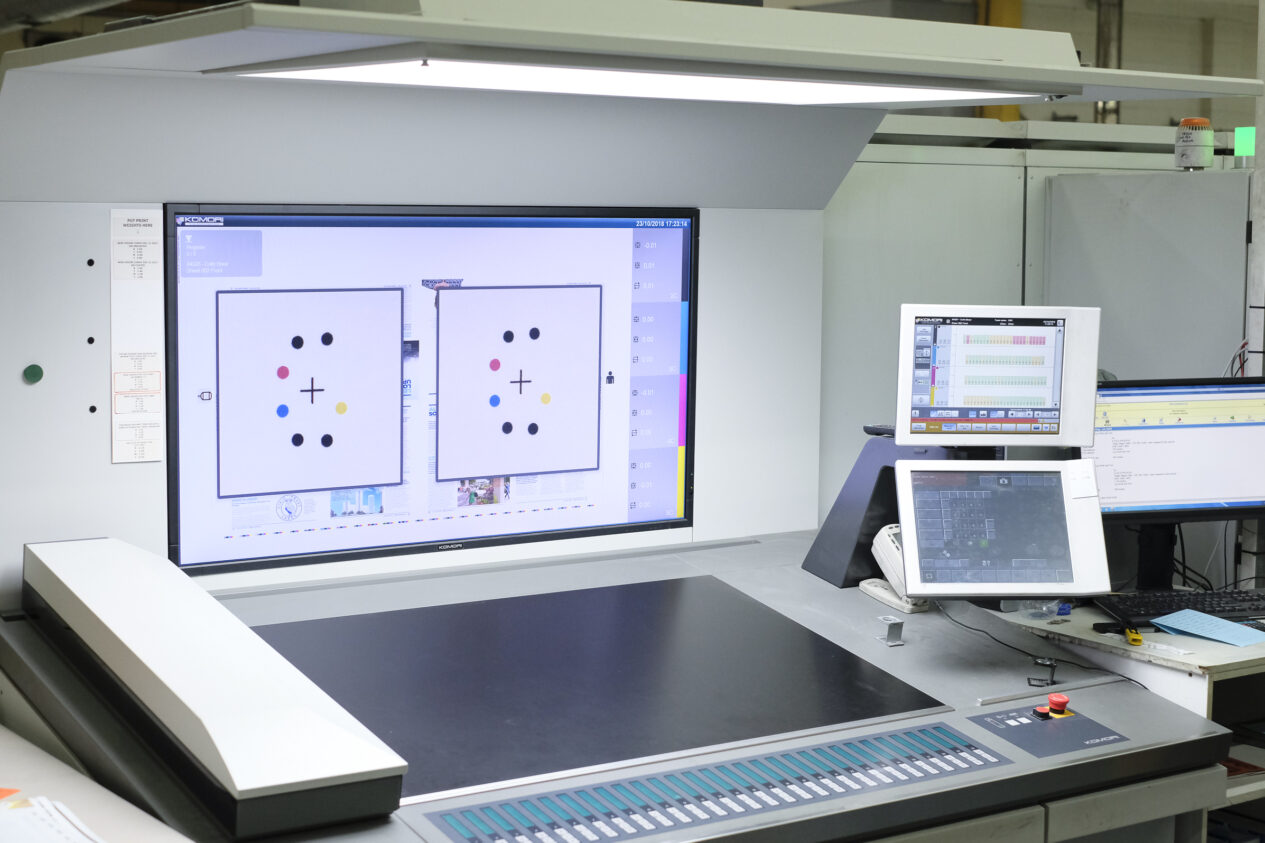

The control deck on TEAM Impression’s latest investment, a Komori B1 UV curing Litho press with interdeck UV curing.

They are FSC, ISO 9001 and ISO14001 certified and there aren’t many materials that can’t be enhanced through one or more of their printing processes but if that isn’t enough you can add varnishing, lamination, embossing, flittering (part of their greeting card plant) and all the incumbent folding, stitching, gluing and hand finishing you could ever need.

Multiple presses are essential in a busy plant; TEAM Impression have 14 printing lines across their processes.

What come’s with this is a wealth of ability and experience to be brave and to be tested. I know that at FESPA where we represent the speciality print community, we have done just this and overall our challenges have been met with an open mind and a guiding hand.

The days events were finished off with a night out in Leeds, where we enjoyed the chance to get to know a little more about our hosts beyond a shared passion for print.

The next morning arrived and we headed off to sign industry trade printer RMC Digital in Hull. We were greeted by Nicole Spencer, Operations Director and Vice President of FESPA UK Association. The business is focussed on wide and super-wide format printing services to the sign industry. With an impressive plant list having required significant investment they are well placed to provide the trade only service to a community who would struggle to justify the investment based on their individual production needs alone.

RMC Digital’s latest installation, Durst RhoLED UV 5-metre-wide print with white and multilayer capability.

The tour led us past Efi and Durst UV inkjet printers with 3.2 metre width and on to two 5 metre wide printers in the capable hands of in-house expert Ray Linford, Technical Manager who ensures that the customers needs are met and I’m sure exceeded. We had a very interesting discussion about jetting velocity adjustments to achieve perfection of multilayer prints. Nicole showed us some stunning prints with selective block out allowing backlit element to show through at night only whilst have no impact on the daylight viewing.

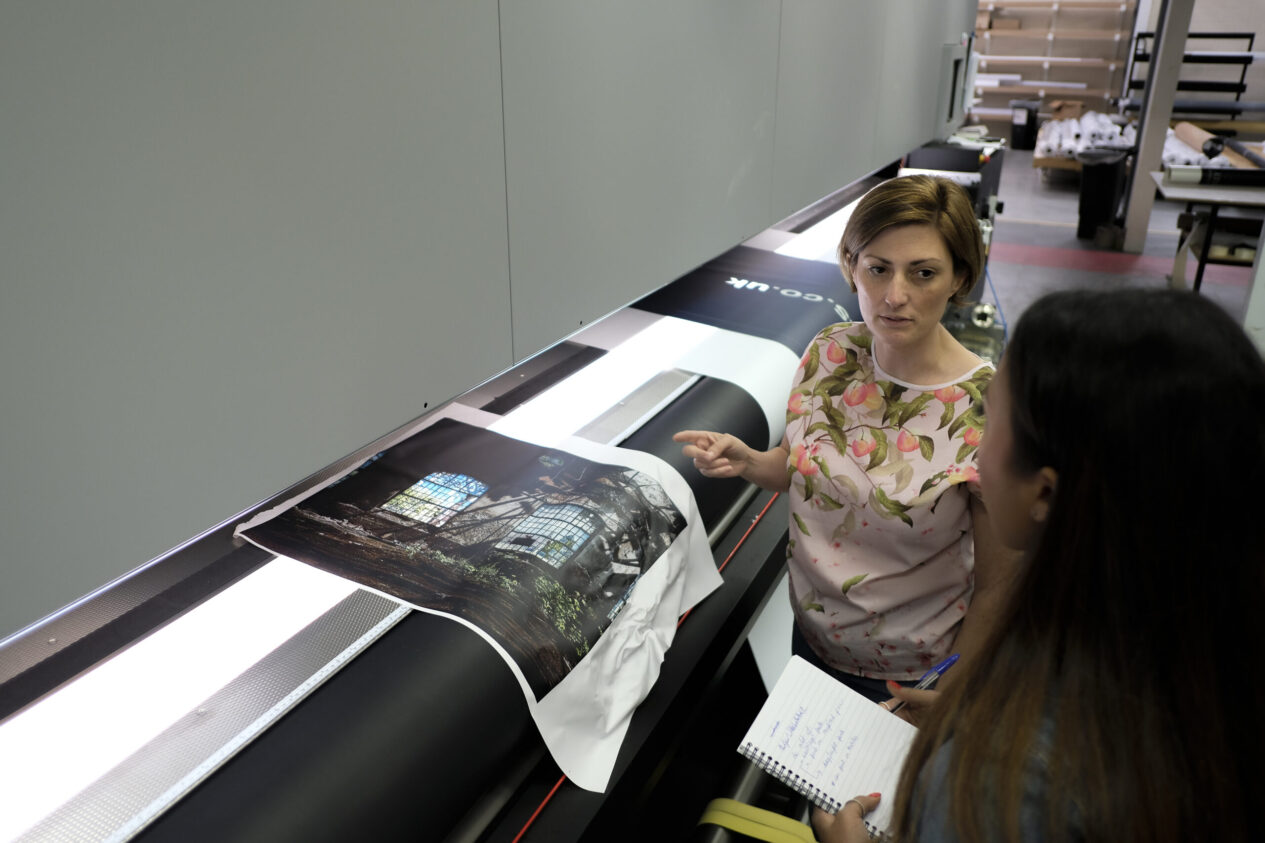

Nicole Spencer showing us the multilayer block out backlit print technique.

You can of course have all the kit but without the talent you’ll never see the best achievable results. RMC Digital’s team provide the reassuring confidence that they will meet any task head on to get the job out on time and at trade rates. Nicole Spencer represents the best of women in print, strong, knowledgeable and progressive – something I think we call all agree form the essential qualities to lead in today’s market.

The top floor of the building has been set up for printing vinyls on a group of Mimaki solvent and UV roll fed printers and laminators which are used to produce a wide range of applications. From simple cut vinyls to printed, laminated and contour cut applications where standard vinyl colour shades won’t suffice.

Following two very busy days we left with a better appreciation of how diverse business models can be applied by progressive businesses to respond to particular customer needs and achieve the growth to continually invest as the markets adjust to the next opportunity in digital disruption.