During the first edition of the ESMA Textile Printing and Sustainability conference, 120 participants from 15 countries attended. The conference focused on all critical factors and global trends that are influencing the textile market whilst looking towards the future. This article offers a summary of the presentations that occured on day 2 as well as listing the key trends.

The conference featured experts from both screen and inkjet printing and featured 25 presentations which focused on best practice, new application fields, automation, and sustainable business models as well as the benefits and challenges of each technology choice.

In this article we look at the presentations that took place on day 2 of the conference including takeaways from each presentation. To read the previous article that discussed trends from day 1 of the conference please visit here.

The key trends that were discussed on Day 2 were:

- The textile industry is one of the most hazardous sectors with global environmental impacts (according to A.K. Roy Choudhury, 2015) and is the second largest polluter in the world, with textile dyeing and printing being key contributors.

- Approximately 20% of industrial water pollution comes from textile manufacturing.

- Today’s existing systems are being influenced socially, politically, and economically leading towards more circular models.

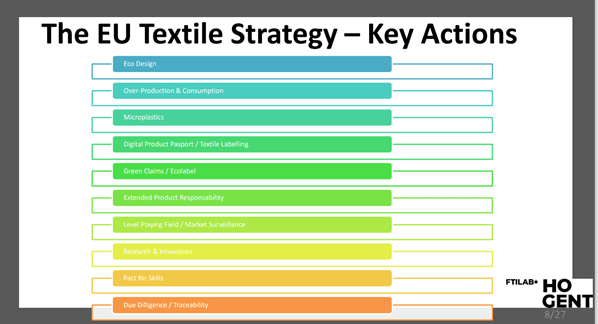

- The EU’s Textile Strategy and the commission’s 2030 vision for textiles will ensure that all textile products in the EU market will be durable and recyclable, free of hazardous substances, products will respect social rights with circular rather than disposable clothes becoming the norm.

- The industry needs to reduce water, carbon footprint, production costs and increase efficiencies, equipment, application flexibility and deliver colour vibrancy, hand feel and wash fastness.

- Inkjet printing can save water, energy, and raw materials. It enables businesses to support the United Nations Sustainable Development Goals 6 (improve water quality by reducing pollution), 7 (affordable and clean energy), 9 (industry, innovation, and infrastructure) and 12 (responsible consumption and production)

- New digital pigment inks are the more sustainable alternative to conventional direct-to-fabric ink technologies where softness limitations allow.

- There are numerous benefits in using pigment inks for DTG printing which include light fastness, easy production process, they are not hazardous and are compatible with many fabrics and blends.

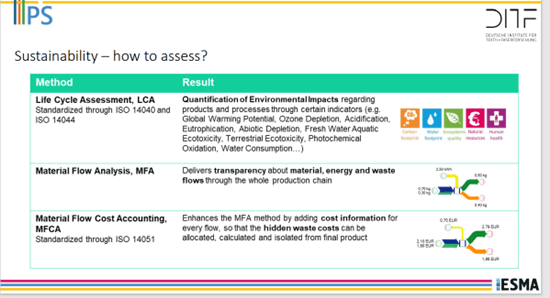

- There are 3 common methods of assessing sustainability, these include Life Cycle Assessment, Material Flow Analysis and Material Flow Cost Accounting.

- Businesses must ensure the design of products are sustainable.

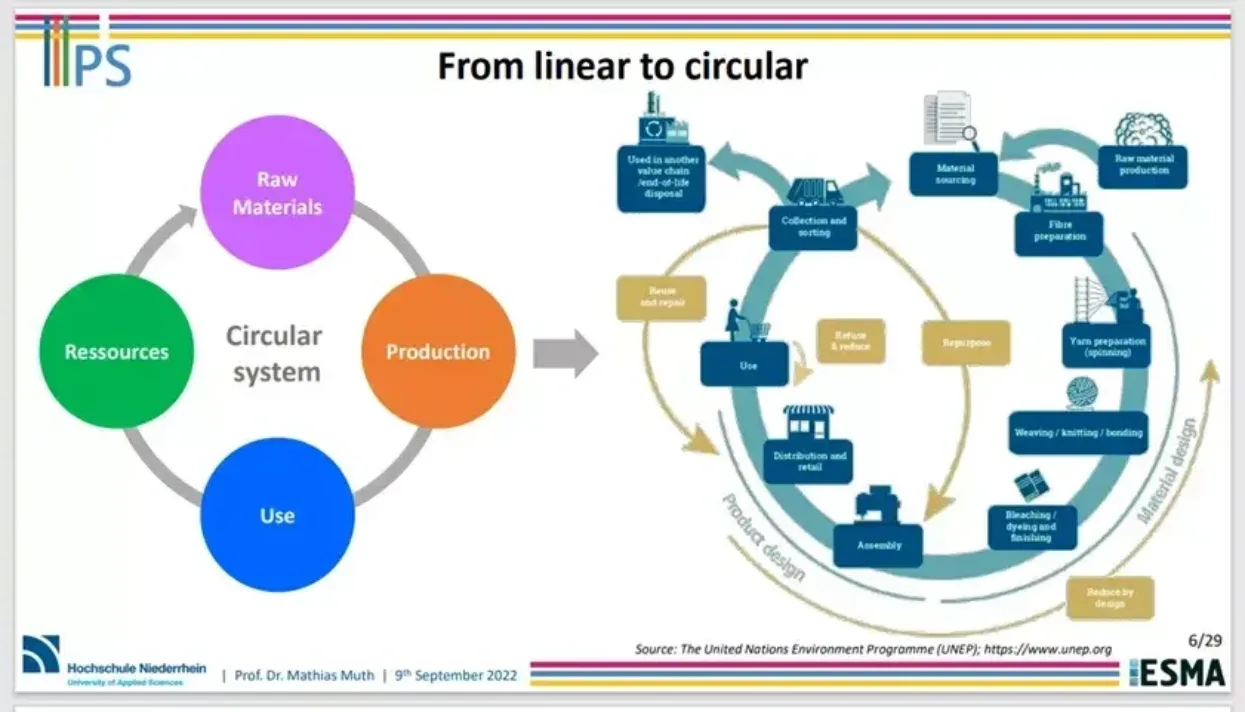

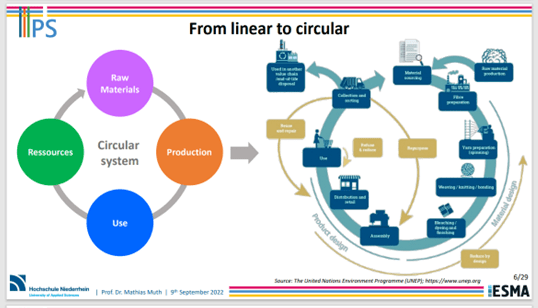

- Businesses must move from a linear model to a circular model to become more sustainable.

Day 2

KEYNOTE: COURAGE! A PLEA FOR A GOOD FUTURE | Bianca Seidel from Bianca Seidel Consulting

Image Credit: taken from powerpoint presentation from ESMA TPS 2022 by Bianca Seidel from Biana Seidel Consulting

Bianca Seidel is a pioneer and expert in sustainable fashion, sustainable fashion design, eco-design, and sustainable management. Bianca discussed the reality of climate change and how today’s existing systems are changing socially, politically, and economically towards more green and sustainable ones. Bianca made an appeal to the audience and the community to actively transform the industry for a better tomorrow.

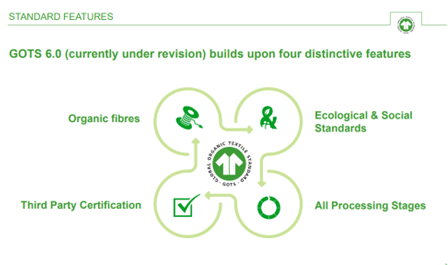

KEYNOTE: GLOBAL ORGANIC TEXTILE STANDARD: FOR THE PEOPLE AND THE PLANET | Juliane Ziegler from Global Organic Textile Standard

Image Credit: taken from powerpoint prentation from ESMA TPS 2022 by Juliane Ziegler frrom GOTS

Juliane Ziegler is a GOTS representative in Germany, Austria and Switzerland and is responsible for the consultation of textile brands, manufacturers, and suppliers on GOTS and sustainability. GOTS is the worldwide leading textile processing standard for organic fibres, including ecological and social criteria. GOTS has a vision that organic textiles will become a part of everyday life, enhancing people’s lives and the environment.The standard is set and implemented by a global standard non-profit organisation and every 3 years the standard is revised to reflect the developments and innovations within the industry. All steps in the processing, manufacturing, and trading of organic textiles are covered by GOTS. GOTS ecological and social criteria must be met by all processors, manufacturers, and traders to ensure companies are diligent. GOTS also helps obtain a leadership position regarding the UN SDGs.

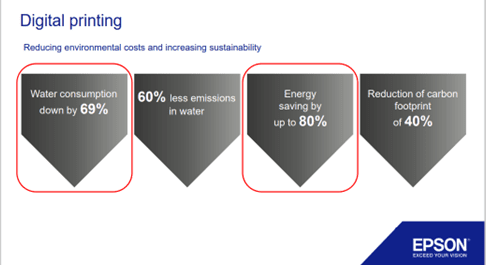

HOW EPSON TECHNOLOGY AND THE TEXTILE INDUSTRY CAN WORK TOGETHER TO IMPROVE SUSTAINABILITY | Duncan Ferguson from Epson

Image Credit: taken from powerpoint presentation from ESMA TPS 2022 by Duncan Ferguson from Epson.

Duncan Ferguson is Vice President who is responsible for the commercial and industrial printing businesses for Epson in Europe. Duncan previously worked for Shell and Kodak and joined Epson in 2003 and has over 20 years of experience in digital textile printing. Duncan provided an update on Epson’s latest Precision Core printhead technology and Epson’s commitment to sustainability and particularly the 17 United Nations Sustainable Development Goals. Epson aims to use 100% renewable energy across the group by 2023 and have put aside 770 million euros for the next 10 years to focus on creating sustainable technologies. Duncan expressed that by 2030 the industry is expected to throw away 134 million tonnes of textiles a year. Digital printing reduces the environmental costs and sustainable water usage and increases sustainability. Duncan emphasizes the need for the industry to move to a circular model that will feature localised production, with shorter distribution increasing the life span of clothes and thus enabling recycling.

HOW CAN INKJET PRINTING HAVE AN IMPACT ON REACHING OUR SUSTAINABLE GOALS | Jan Baden from Druckprozess

Image Credit: taken from PowerPoint presentation from ESMA TPS 2022 by Jan Baden from Druckprozess.

Jan Baden has a long career in the inkjet industry. In 2014 he founded Druckprozess as a consultancy agency for industrial inkjet applications. The production of textiles is always moving to places where there are cheap production costs. Jan explained that utilising inkjet printing can allow business to support United Nations Sustainable Development Goals 6 (improve water quality by reducing pollution), 7 (affordable and clean energy), 9 (industry, innovation, and infrastructure) and 12 (responsible consumption and production). Druckprozess has created 2 inkjet solutions to help businesses reach their sustainable goals. Foulard is an analogue padding treatment to prepare fabric for printing ensuring smooth coating to both side and promoting better ink adhesion. DigiTEX is a digital treatment and finishing system, the application of functional surface treatments using instant dry technology from Lamba Technology.

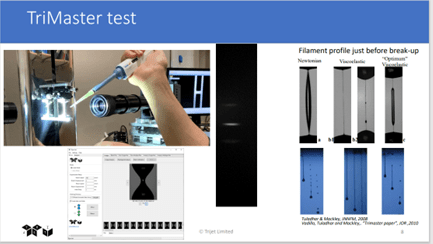

UNDERSTANDING TEXTILE INKJET INKS AND FACTORS INFLUENCING THE JETTING BEHAVIOUR | Dr. Tri Tuladhar from Trijet

Image Credit: taken from powerpoint presentation from ESMA TPS 2022 by Dr. Tri Tuladhar from Trijet

Dr. Tri Tuladhar has over 20 years experience in R&D and has a PhD from the University of Cambridge in Chemical Engineering. He leads Trijet Limited who specialise in all aspects of inkjet printing including complex rheological characterisation and fine-tuning of inkjet inks, formulation of speciality paints, glass enamels and functional inks, jetting optimisation and developing customised rheological tools for such applications. Dr. Tri discussed how small variations within ink viscoelasticity influences upstream flow dynamics and jet break-up mechanism downstream. He presented two bespoke rheological tools, TriPAV and TriMaster that both quantify complex fluid rheology of low viscosity textile inkjet inks in a laboratory environment stimulating inkjet printing conditions. Dri Tri emphasized the need to fully understand the influence of these dynamic properties of inkjet inks and doing so will help formulate and fine-tune reliable, high viscosity inkjet inks and speed up waveform development. In essence, his work centres around the balance of ink rheology and electronic waveforms to achieve the highest quality and jetting speed potential.

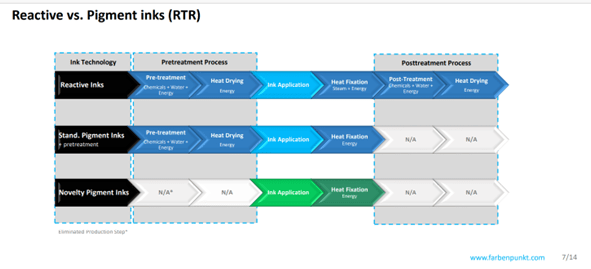

PERACTO PIGMENT INK TECHNOLOGY: INNOVATION FOR WATER AND ENERGY REDUCTION IN DIGITAL TEXTILE PRINTING | Theresea Schmaus and Etienne Stevnink from Farbenpunkt

Image credit: taken from presentation at ESMA TPS 2022 by Theresa Schmaus and Etienne Steveninck from Farbenpunkt

Theresa is the lead for Business Development at Farbenpunkt GmbH and has over 7 years experience in Textile Design. Etienne is the Founder and Managing Director of Farbenpunkt GmbH and has over 30 years experience in textile engineering and textile chemistry. Both describe how currently the industry is cautious regarding the implementation of pigments based on performance misconceptions even though it saves significantly on environmental resources. The textile industry is the second largest polluter in the world, with textile dyeing and printing being key contributors to its negative impact. The industry needs to reduce water and its carbon footprint, production costs and increase efficiencies of equipment and application flexibility whilst delivering improved colour vibrancy, hand feel and wash fastness. Both state that novelty pigment inks should be used across digital inkjet printing due to the benefits to the environment as mentioned previously. Novelty pigment inks do not require pre- or post-treatment and are a more sustainable alternative to conventional direct-to-fabric ink technologies. The right ink technology is key to maximizing the impact of digital textile printing.

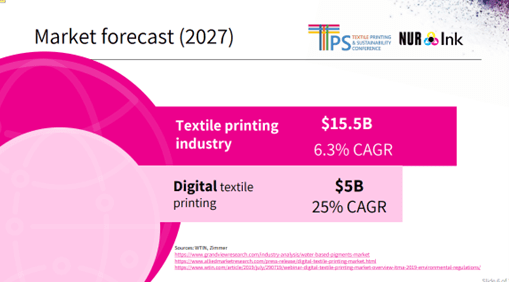

LATEST INNOVATIONS IN WATER-BASED PIGMENT INKS FOR DTG | Eliav Priel from Nur Ink

Image credit: taken from presentation at ESMA TPS 2022 by Eliav Priel from Nur Ink

Eliav has over 25 years of international business management experience in digital printing markets. Nur Ink Innovations develops and manufactures water-based pigment inks for inkjet digital printing. Eliav described numerous advantages in using pigment inks for DTG printing, these include light fastness, easy production process, they are not hazardous, compatible with multiple fabric types. However, there are limitations which include a stiff hand feel, limited wash resistance, limited rub resistance etc. There are developments in low temperature curing ink (LTCI) which eliminates dye migration which allows printing to be executed onto dark synthetic garments. LTCI also allows printing in layers to create a 2.5D structure and printing in a single-pass architecture. SolGel technology provides faster ink drop placement and fixation.

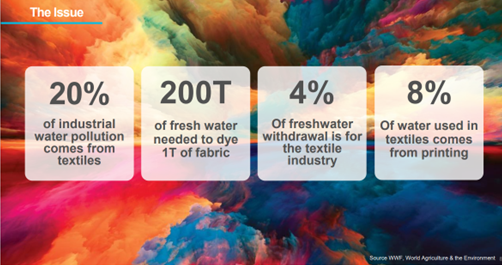

BRIDGING THE GAP TO SUSTAINABILITY IN TEXTILE PRINTING: ASSESSING THE CURRENT LANDSCAPE AND INK CHEMISTRY STRATEGIES TO MEET THE MARKET CHALLENGES |Dr. Simon Daplyn from Sun Chemical

Image credit: taken from presentation at ESMA TPS 2022 by Dr. Simon Daplyn from Sun Chemical. Statistics provided by WWF, World Agriculture & Environment

Dr. Simon Daplyn is responsible for the management of product and marketing input at Sun Chemical. He is currently responsible for determining the product strategy for the business in digital textiles with a focus on sustainable technology developments. Currently the textile industry is producing copious amounts of waste with 20% of industrial water pollution coming from textiles. Dr Daplyn mentioned how the current outlook is changing with government legislation evolving, brands setting their own sustainability standards and consumers wanting to make ethical and sustainable purchases.

Image credit: taken from presentation at ESMA TPS 2022 by Dr. Simon Daplyn from Sun Chemical. Statistics provided by WWF, World Agriculture & Environment

Dr. Daplyn reiterated that in order to instigate change sustainability must be taken into account from the design stage. It is important to be careful when choosing materials, avoiding creating unnecessary waste, create longer lasting products that are durable and ensure the chemistry is green with no hazardous chemicals. Brands must commit to this production evolution with digital and sustainability offering fashion’s biggest opportunities for growth, while supply chain pressures will challenge the industry in 2022.

KEYNOTE: DIGITAL FASHION AND TEXTILES, A CHALLENGE AND OPPORTUNITY FOR INDUSTRY AND EDUCATION | Alexandra De Raeve from HoGent

Image credit: taken from presentation at ESMA TPS 2022 by Alexandra De Raeve from HoGent.

Alexandra began her career in the textile industry in 1988 and has (co)-authored over 80 publications in national and international journals and conferences. HoGent university currently has over 40,000 students. Alexandra discussed the EU’s Textile Strategy and the commission’s 2030 vision for textiles which would ensure that all textile products in the EU market will be durable and recyclable, free of hazardous substances, products will respect social rights with circular rather than disposable clothes becoming the norm. Digitization and sustainability challenges the industry, but also educates it. A healthy connection between research and education is the key to training future-oriented professionals.

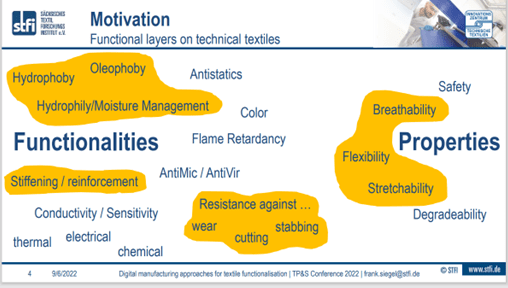

DIGITAL MANUFACTURING APPROACHES FOR RESOURCE-SAVING TEXTILE FUNCTIONALISATION | Dr. Frank Siegel from Saxon Research Institute

Image credit: taken from presentation at ESMA TPS 2022 by Frank Siegel from Saxon Research Institute

Frank has spent over 13 years studying the complexity of functional printing and during the last 7 years he has focused on textile functionalisation by printing processes. Frank described how both digital and contactless manufacturing methods are allowing technology for resource-saving production processes. In comparison to screen printing, digital printing technologies can apply functions that are customized, contactless and on 3D textile surfaces. Frank predicts in the future that digital technologies such as UV-laser imaging, drop-on demand printing and single nozzle jet dispensing will lead to new design possibilities and functionalities.

RESOURCE EFFICIENCY THROUGH DIGITISATION | Dr. Thomas V. Fischer from DITF Denkendorf

Image credit: taken from presentation at ESMA TPS 2022 by Dr. Thomas V. Fischer from DITF Denkendorf

Dr. Thomas V Fischer is the Deputy Director of the Centre for Management Research and focuses on digital engineering, sustainability, and the applications of AI methods in the textile industry. DITF are Europe’s largest Textile Research Center. Dr Fischer emphasizes how digital printing technologies are the cornerstone of digital textile microfactories. These type of microfactories provide a vast range of use cases and possibilities for resource efficiency and sustainability. He described 3 different methods of assessing sustainability which include Life Cycle Assessment, Material Flow Analysis and Material Flow Cost Accounting. Digital textile microfactories are a digital platform for consistent processes. This concept can be achieved by using suitable workflows, process integration and business models. Digital Textile Microfactories have a huge potential for nearshoring, small lot sizes and individual products.

SUSTAINABILITY IN THE TEXTILE INDUSTRY: WHERE DO YOU GO WITH UN GOALS, CIRCULAR ECONOMY, REACH AND ECO LABELS? | Professor Mathias Muth from the University of Applied Sciences Niederrhein

Image credit: taken from presentation at ESMA TPS 2022 by Professor Mathias Muth from the University of Applied Sciences.

Mathias Muth is a professor for Textile Printing Technologies at Hochschule Niederrhein at the University of Applied Sciences in Germany. He teaches textile printing, dyeing, coloration, and functionalisation. Mathias envisions that in the future, reconciling ecology and economy will become a fundamental challenge along the whole textile chain. Currently the textile industry is one of the most hazardous sectors environmentally (according to A.K. Roy Choudhury, 2015). The European Commission will introduce a new plan for businesses in the textile ecosystem by the end of 2022. The aim is to successfully achieve the green and digital transitions and increase its resilience. Mathias predicts that the transition from a linear model to a circular model is essential and inevitable. Mathias also emphasized the importance of designing future products with the aim of recycling them. The end-of-life must be considered during the design stage and all value-added stages should be taken into account. There are several challenges regarding establishing a circular economy that concern ecology, economy, and society. Such challenges include competitive prices, moving away from fast fashion, increasing longevity and durability and more.

FESPA’s Sustainability Spotlight feature at FESPA Global Print Expo 2023 will provide useful, informative and actionable advice to address the needs of People, Planet and Profit. Taking place from 23rd May – 26th May 2023 at Messe Munich, German. All conference sessions are free to attend that feature topics to provide the toolkit you need to reduce costs by optimising energy and resources. For more information on Sustainability Spotlight please visit here. If you would be interested in speaking at the feature please complete the enquiry form here.