The printhead is the core of any inkjet printer, however most printers only consider them whey they do not work as expected. Sonja Angerer shares the top 10 questions for beginners and professionals regarding inkjet printheads and how to find the right printhead for your business and needs.

1. How long have inkjet printheads existed?

The first functional digital printers with inkjet heads were introduced to the market by IBM in the early 1970s. However, they were intended for industry use only. In the mid-1980s, HP and Epson launched inkjet printers for everyday office use. Initially, the printers were still black and white, but towards the end of the 1980s the first colour printers that worked on paper up to A3 format were introduced. At the end of the 1990s, when digital large-format printing launched, inkjet printheads became more powerful, and many needed to be built into a printer to enable multi-colour printing.

2. Where are CIJ printheads used?

The first inkjet printers used the Continuous Ink Jet (CIJ) process, also known as Continuous Flow or Continuous Drop. The nozzles produce a continuous stream of ink droplets that are passed through an electric field that deflects or intercepts the droplets as needed. The droplets that are not required for the print are re-directed to a collection container and eventually reused.

CIJ printing uses high speed with very fine, uniform droplets, but ink consumption is typically higher than DoD inkjet. They are therefore used for fast printing of addresses or simple labels, as well as for some industrial applications.

3. What is DoD inkjet?

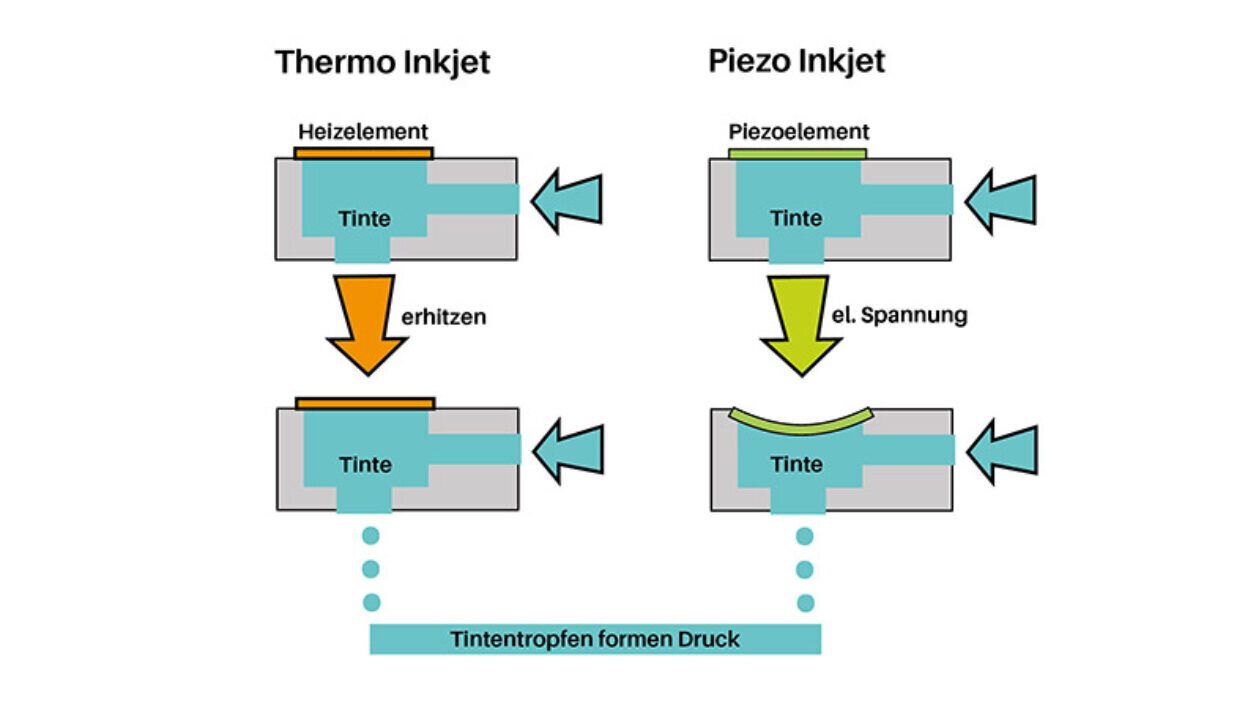

With DoD (drop-on-demand) inkjet printheads, every droplet produced from the nozzle is also placed on the substrate. In thermal inkjet and bubble jet, the droplet is produced by heating the ink in the nozzle. In piezo inkjet heads, this is done by a crystal that is activated by electricity. In the graphic arts industry and for office printers, DoD inkjet is most common.

4. How do piezo inkjet printheads work?

Piezo inkjet printheads use piezoelectric crystals that bend when an electrical voltage is applied. This will reduce the size of the ink chamber and push a drop out of the nozzle. This technique was developed by Epson in the late 1980s and allows for high precision and reliability of the printheads. Piezo inkjet printheads can also produce different drop sizes. They are manufactured by Epson, Fujifilm, Konica Minolta, Kyocera, Toshiba and Xaar, among others.

Many different ink formulations can be used in piezo heads. This is because the ink does not need to be boiled. As a result, heat-sensitive and highly volatile components, that are problematic with thermal inkjet, are also suitable.

Image Credit: S. Angerer

5. What are the characteristics of thermal inkjet heads?

Thermo inkjet printheads use a small heater that vaporises the ink in the nozzle chamber. This creates a bubble that expels the drop from the nozzle. The basic principle was patented almost simultaneously by HP and Canon in the late 1970s. However, the technical details between Canon Bubble Jet (video) and the HP Thermo Inkjet printheads are different.

Thermal inkjet heads are generally less expensive and easier to produce than piezo inkjet printheads. However, they have a shorter lifespan and can usually only produce one droplet size. HP’s Pagewide technology (video) is also a variant of the thermal inkjet process.

6. What is a Greyscale / Grayscale Inkjet Printhead?

Grayscale printheads are also called “variable dots” because they allow for fine gradations and precise details without additional head passes. To do this, they emit ink droplets in different volumes. Depending on the model, the volume ranges from a few picolitres to excess of 50 pl.

Different droplet sizes enable better image quality for the human eye with the same physical nozzle density. For example, sharp edges or letters appear smoother and more pleasing by setting smaller drops. The accuracy of the positioning and uniformity of the droplets, their minimum and maximum size, the number of printing inks and the viewing distance also contribute to the perceived image quality. Greyscale printheads typically are Piezo technology.

7. What does a “binary” inkjet printhead do?

Binary inkjet printheads only offer 2 options: droplets or no droplets. This means that each drop is the same size. The smaller the drop, the slower (but more accurate) the printer. This is because with very small droplets, more head passes per motif are required. Binary heads are often used for industrial inkjet printing because they can quickly apply larger quantities of liquid such as varnish or primer.

8. What are the benefits of MEMS printheads?

MEMS stands for micro-electro-mechanical system, i.e. any system whose components have dimensions of application 1 micrometre.

When referring to inkjet printheads, MEMS is used to signify a manufacturing process like silicon-based computer chips. For this reason, they are also called Si-MEMS or Thin Layer / Thin Film inkjet. The first Si-MEMS printheads were intended for office printers and home devices with thermal or bubble jet technology.

Today, there are also piezo heads made with silicon wafers, such as Epson PrecisionCore heads (video)

9. What is the difference between single-pass and multi-pass heads?

Whether a printer is called a single-pass or a multi-pass device depends on the whole printing process, not just the inkjet heads. In multi-pass, the printing unit moves several times over a spot on the substrate. As a result, less productive inkjet print heads can be used. In single pass printing where the substrate passes perpendicular under the pressure beam, so the print beam passes every spot of the substrate only once.

Single-pass printing mainly uses water-based ink for papers and corrugated board, as well as direct-to-textile printing. EFI single-pass printers of the Nozomi range (video) however work with UV-curable inks. Multi-pass printing is suitable for water-based, solvent-based, latex or UV-curable inks.

10. Do laser printers have printheads?

Laser or toner printers do not have printheads. A laser beam is directed a statically charged roller, so removing the charge in places where no toner should be applied. The printing roller prepared in this way transfers the particles to the substrate and fixes them by heat (video).

Finding the right printhead

While printheads can be purchased individually, for printers, it’s the connection between the inkjet printhead, control, mechanics and software that makes all the difference. That’s why digital printing machines are delivered with predefined print heads. The configuration is not changeable. Therefore, only inks approved for the print head installed in the machine can be used.

Piezo printheads are usually more expensive and last longer than thermal printheads. With some printers, thermos inkjet heads get exchanged together with the ink tank. In general, the more print heads are installed, the higher its Total Cost of Ownership (TCO).

However, the cost of actual inkjet printhead replacement depends on many other factors: Can the inkjet printhead be installed and aligned by operators in the field? Does a manufacturer’s technician need to be involved? Can printheads be regenerated and possibly re-used? Is it a printhead model that is very common on the market, and can therefore also be obtained from many sources?

Printers should therefore continue to seek advice from manufacturers or specialist retailers.