White and clear inks, now common in digital printing, offer significant value by enabling diverse, high-impact applications. Despite white ink’s technical challenges (particle sedimentation, infrequent use) requiring specific printer features, both white and clear inks allow for multi-layered graphics, vibrant prints on non-white substrates, tactile textures, and spot embellishments. These capabilities help printers differentiate services and emphasize value over price.

The use of white ink has become increasingly common over the last ten years or so, starting with UV-curable printers but now also including eco-solvent and latex. In addition, a growing number of vendors are also offering clear ink. However, not all printers include these inks, which are normally offered as optional extras, so what are the advantages of these extra inks and are they worth the extra cost?

There are two main issues to consider before choosing to fit a white ink channel. Firstly, white ink contains very large particles of titanium dioxide, which is the pigment that produces the white colour. These particles are heavy and can sink to the bottom of the ink tank, and they can cause blockages in some inkjet printheads. However, neither of these should present a serious obstacle to a modern printer. In theory the ink dispersion should be able to hold the pigments evenly suspended in the ink but it’s common for the white ink tank to be fitted with a system to agitate the ink – to stop any sedimentation where the heavier particles collect at the bottom of the tank.

The white ink channel should also use recirculation, where the ink is forced to circulate around the ink system, which can also help to prevent sedimentation. However, in some cases the printer vendors may use a limited form of ink recirculation, between the tank and the printhead. For white ink, it’s best if the recirculation also includes the printhead itself down to the backs of the nozzles to reduce the risk of any dried ink collecting around the nozzles.

This is because of the second issue with white ink – you don’t need to use it on every job. This means there may be long periods when the white ink channels are not in use. Inkjet heads do not like to be left idle so the best way to prevent nozzle blockages is to keep the heads running. Recirculation at the print head – not just the ink system – can help with this. For this reason, many printers may use different heads, or a different variant, for the white ink channels. All this means that, unlike other colours, it’s difficult to retrofit white ink channels to most printers.

White ink will normally be supplied in smaller cartridges than the other colours – because it’s not as heavily used – and will usually cost more per litre than the other colours. However, the range of effects that rely on white ink should allow you to charge more overall so that most users report that the white ink easily pays for itself.

One common effect is to print in multiple layers, for backlit films or day/ night window graphics. These effects involve printing two separate images on the same substrate at the same time. For this, you need a white layer to separate the different images and prevent one showing through the other.

White ink is also useful as an undercoat when printing to non-white materials, to help separate the colours from the background. Many substrates are white but there are also many metallic or mirrored substrates as well as wood and corrugated boards, plus in some cases it may simply be cheaper to use a coloured material. And in some markets, such as textiles, white ink is essential to be able to print to darker materials.

The same is also true when printing to clear films, where a white underlay can help the graphics to stand out. Equally, white ink on its own on a clear film can be quite striking, particularly for window graphics.

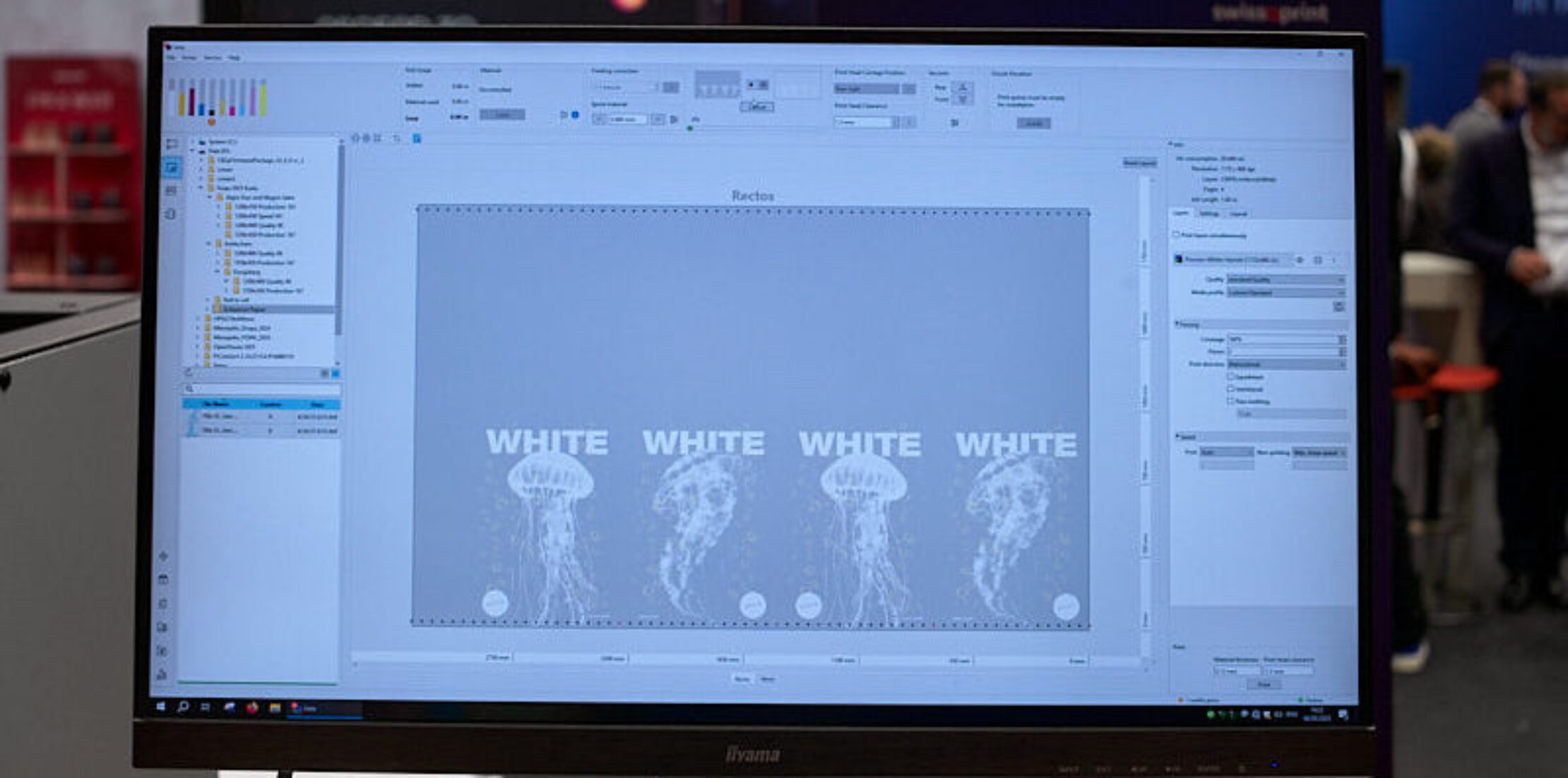

White can also be used for spot effects, to highlight some text or to help accentuate particular areas of a graphic and to add extra ‘pop’. It’s also worth noting that the upcoming Adobe PDF Print Engine, which forms the basis of many of the most popular RIPs, will include a new feature for automatically setting up white masks to remove some of the hassle in doing this at the pre-press stage.

Clear or varnish ink

Given all the advantages, it’s hard to think back to a time when white ink was once seen as an unusual option. Nowadays it’s become quite common and most print service providers should have at least one printer that can offer white. So naturally printer vendors are looking for new effects to offer, with clear ink, which is often referred to as varnish, now becoming popular.

There are no technical challenges in managing clear inks so the only issue is the cost of dedicating a printhead and ink channel for an ink that will not be used on every job.

Instead clear ink or varnish is best used for spot coating to highlight specific elements of a design, such as a logo or part of an image. In theory you could also use it to coat a whole image but you would have to calculate the costs versus the alternatives. Flood coating a whole image, especially if you only have one channel of clear ink, is likely to slow down the printing, plus there is the cost of the ink itself. There are dedicated flood coaters, usually using an anilox roller rather than an expensive inkjet head. And you may find that laminating a clear film on top is both cheaper and more effective.

Spot coating on the other hand can only really be done with an inkjet head, and can enhance fine details. Some UV printers can achieve a glossy effect, even a spot gloss, by manipulating the curing timing and direction, but in most cases a clear ink will produce a more pronounced effect.

Another advantage of a clear ink on a UV printer is that you can also print and cure multiple layers of clear ink on top of each other to produce a highly textured effect that can be both visually stunning and add an extra tactile dimension to a graphic. In some cases, it’s even possible to produce braille effects. This textured printing will slow down the printer, but if the textured effect stands out then you can charge accordingly for the time taken.

In conclusion, one of the main lessons from the recent Fespa Global exhibition in Berlin is that many print service providers feel a need to increase the range of applications and effects that they can offer. This is partly to differentiate themselves from their competitors but also to avoid purely competing on price. White ink, and increasingly also clear ink, offer a very cost-effective way to demonstrate creative flair and design skills, and that can help to shift the conversation away from pricing and towards added value.