Nessan Cleary shares the range of options currently available for printing corrugated packaging. This range varies from compact machines to large format printers.

Over the last decade we’ve seen a gradual shift to online shopping, which was turbocharged during the pandemic with many of us now ordering at least some part of our purchasing over the Internet. This in turn means that in-store displays and retail advertising are missing some part of their market. This has led many brands to look again at their packaging, particularly delivery boxes, as a way of reconnecting with their customers.

So, it’s perhaps not surprising that we are suddenly seeing a lot of new presses coming to market that are specifically designed for printing to corrugated sheets. In the past, the graphics for these boxes would have been printed either by offset, and then laminated to the corrugated sheets, or by flexo directly to the corrugated boards. But inkjet technology now allows full colour images to be printed direct to board, complete with personalisation for individual customers.

However, corrugated boards are not the easiest material to handle. The quality of the boards varies hugely so that any print system has to include a way to inspect the boards and, if necessary, reject any that are not up to scratch. Even then, many of these boards will exhibit some degree of warping so that most printers will need a reasonably powerful vacuum system built into the media transport to hold the boards flat to prevent the printheads from being hit. And, of course, any print system will have to be able to handle different types of boards, including coated and uncoated.

Another issue is food safety, with many brands and converters preferring to use water-based inks able to comply to standards for indoor contact with foods rather than UV-curable inks. There’s a good argument that food packaging only accounts for a very small part of the total packaging market but equally many printers would prefer to have the flexibility of inks that can cover as much of the market as possible. Besides, in theory water-based inks should be cheaper though this is not always the case!

There are a number of different options, ranging from wide format printers all the way up to large dedicated presses. The main issue is volume and productivity, since packaging tends to involve high volumes with small costs per unit. So although its perfectly possible to print corrugated boards on a large format printer, the trick is to do this at a high enough volume to make a profit. There are several high speed large format printers that can handle the printing but the main issue is getting the boards on and off the printer in a continuous, fast flow. This has led several vendors to integrate automatic loading and unloading systems.

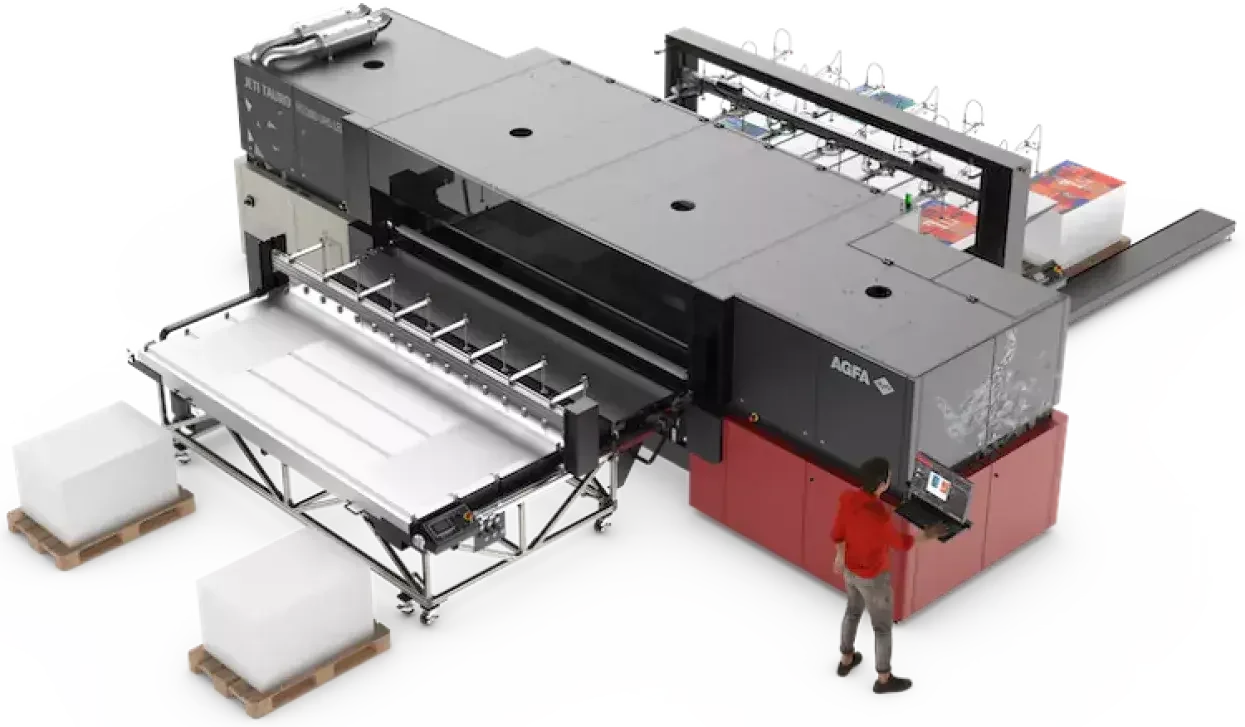

Agfa, for example, introduced a UHS version of its Jeti Tauro H3300 LED printer specifically for the corrugated packaging market as well as the upper end of the sign and display sector. The printer itself is a 3.3m wide hybrid wide format printer using UV ink with LED curing. It can produce up to 600 sqm/hr with the key to this productivity being the highly automated loading and unloading system.

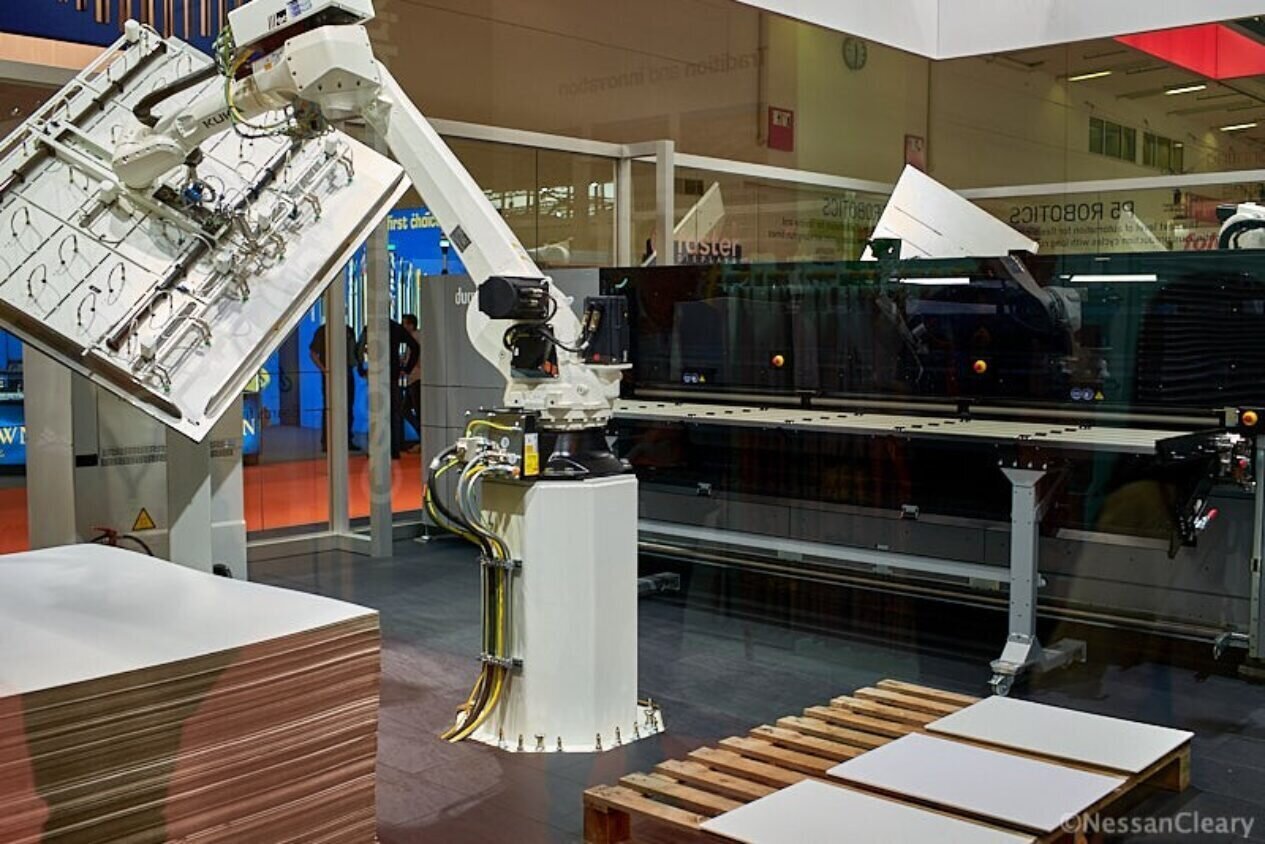

Other wide format vendors, including Durst and EFI have also integrated automated loading and unloading systems around their high end printers to make the most of their print speeds. Several vendors have also introduced robotic loading and unloading systems complete with the option to feed the printed boards direct to a cutting table.

Durst produces a number of hybrid UV printers from its P5 range that are suitable for the corrugated market, particularly when combined with Durst’s P5 robotic system for automated loading and unloading. But Durst also sells the P5 250 WT, which uses water-based inks and is said to comply with food safety standards. This produces a very thin film and is also said to be suitable for interior decoration uses.

Durst's P5 Robotics system is based around two Kuka robotic arms

Mtex NS makes the Multi series of printers for the packaging market, which are relatively compact machines that are cheap enough to justify dipping a toe into this market. The range includes the Multi 1300, which has been designed for short run printing to corrugated for boxes an includes automated feeding and stacking. It uses HP thermal printheads with a water-based pigment ink. It takes boards up to 1.3m wide and 1.6m wide and up to 50mm thick. It can run at up to 27mpm at 300 x 1200 dpi resolution, though the speed drops for higher resolution. Konica Minolta has also rebadged this same machine as the PKG-1300.

Mtex NS makes the Multi 1300 corrugated printer, seen here rebadged by Konica Minolta as the PKG-1300.

EFI has had considerable success with its Nozomi series of single pass printers. These use UV-curable inks and are primarily aimed at the corrugated packaging market. That said, EFI has also created several SD versions for the sign and display market. The company is also working on an AQ version that will use water-based inks, which should be available by the end of this year.

EFI used the recent Drupa show in Germany to introduce a dedicated box making solution called the Packsize Nozomi X5. This is a complete printing and converting line that can take in blank corrugated substrates from four Z-fold supply feeders, print and then form a complete box, all in one line for an integrated on-demand box printing solution. Every box can be a different shape and size, with up to 30,000 possible choices. The boxes are output to a conveyor belt that’s fitted with a label print and apply unit, so that shipping details and hazard labels can be automatically applied to the box.

EFI's Packsize X5 Nozomi box making line.

Xeikon has developed the Idera, which takes coated and uncoated boards up to 1.6m wide and 2.8m long and up to 11mm thick. It uses Kyocera printheads and prints CMYK, using a water-based ink. It also features inline priming and varnishing, which are also water-based to ensure that it can comply with the food safety standards. The print resolution is up to 600dpi and it runs at a speed of 60 to 120mpm. It comes with Xeikon’s X-800 front end and a Caldera RIP.

HP makes several single pass T-series inkjet presses that can be used to print the top liners ready for laminating to corrugated boards. The company also makes the extremely large C550 press, which can print directly to corrugated boards. It uses HP’s thermal printeads, first jetting a primer to the boards, then the water-based inks, followed by an overprint varnish. It runs at 90mpm.

There’s not room here to list all of the different options, but it should be clear that there are a range of different options, from compact machines to large format printers, and up to very large dedicated corrugated presses.

To discover the latest content that covers a wide range of sectors including corrugated packaging, automation and inks sign up for FESPA’s free monthly newsletter FESPA World available in English, Spanish and German.