Vehicle wrapping is a popular and cost-effective way to transform any vehicle. However, issues can arise if the vehicle is wrapped incorrectly. This article tackles the 5 most common problems when wrapping a vehicle.

When it comes to vehicle wrapping, there are numerous potential issues that can arise. Fortunately, most of these issues are easily fixable. Here are the most common vehicle wrapping issues and how to tackle them to ensure you have the best quality wrap.

1. Poor Installation of Wraps

Bubbles and wrinkles are common with low quality wrapping film.

Image Credit: S. Angerer

2. Bubbles and Wrinkles in Vehicle Wrap Film

If the vehicle wrap has bubbled or wrinkled, there is a high chance that the film or laminate was not given enough time to cure correctly before being stretched over the surface of the car. If the film was printed using Eco Solvent inks, it is important to ensure that it is given 24 hours to properly cure before applying any laminate. When storing rolled-up film for curing, it is crucial to avoid storing it upright on the floor, this avoids damaging the glue with scratches or solvent buildup. Prior to attempting to strain, pull, or apply pressure to any section of a car wrap, it is strongly advised to give it another 12 hours following lamination.

However, if the vehicle wrapping film is printed with latex inks on appropriate substrates, lamination is not necessary.

Manufacturers of coloured and printable films for vehicle wrapping such as 3M, Avery, Hexis or Orafol, usually recommend laminates to go with their products. This can be a good idea as using a cheaper, clear film option can prove to be more expensive later on. Another factor to consider is temperature, as this can have an impact on film’s ability to stretch.

For wrapping curved surfaces, use cast film only to avoid problems.

Image Credit: S. Angerer

3. Poor Adhesion Issues

When vehicle wrap adhesive is applied incorrectly or the film is of poor quality, it will not stick to the vehicle’s surface. To fix this, it is important to use a high-quality vehicle wrap adhesive that meets industry standards and to test its strength and durability prior to application.

Even some of the best brands can have adhesion issues on certain vehicles. A common reason is that the surface has not been properly cleaned. A good recommendation is to ensure the vehicle has been washed and cleaned before being handed over by the customer. Before installation, it is also crucial to ensure that wherever the car has been parked that the temperature is no higher than 20 degrees. A surface cleaner should also be used e.g. Avery, on any surface that needs to be wrapped.

Wrapping a brand-new car from the assembly line comes with it’s own issues. The colour itself can take up to 6 weeks to set with the adhesive if it is not fully cured. Another factor to consider is that manufacturers sometimes change the varnish they use, therefore it’s characteristics may change dramatically.

If possible, use the same printer and substrate for recurring wrap jobs – or get ready to learn some serious colour management skills.

Image Credit: S. Angerer

4. Poor Colour Matching

A vehicle wrap is only as good as the colours it produces, if the colour does not match with the vehicle’s original paint job or custom colour then something has likely gone wrong during production. To avoid this problem, always ensure you know the car’s original colour codes or previously used coloured film and submit the information on the vehicle wrap order.

When only a part of the wrap is replaced, colour consistency issues frequently develop. This can be due to the UV rays changing the surface and hues of the film and print. Therefore, it is usually a good idea to replace the whole side of a vehicle wrap to make discrepancies less noticeable.

For printed wrapping film, make sure to print every part of the design and any replacements using the same printer, using a consistent RIP and substrate. If this is not possible, try to emulate using advanced colour management.

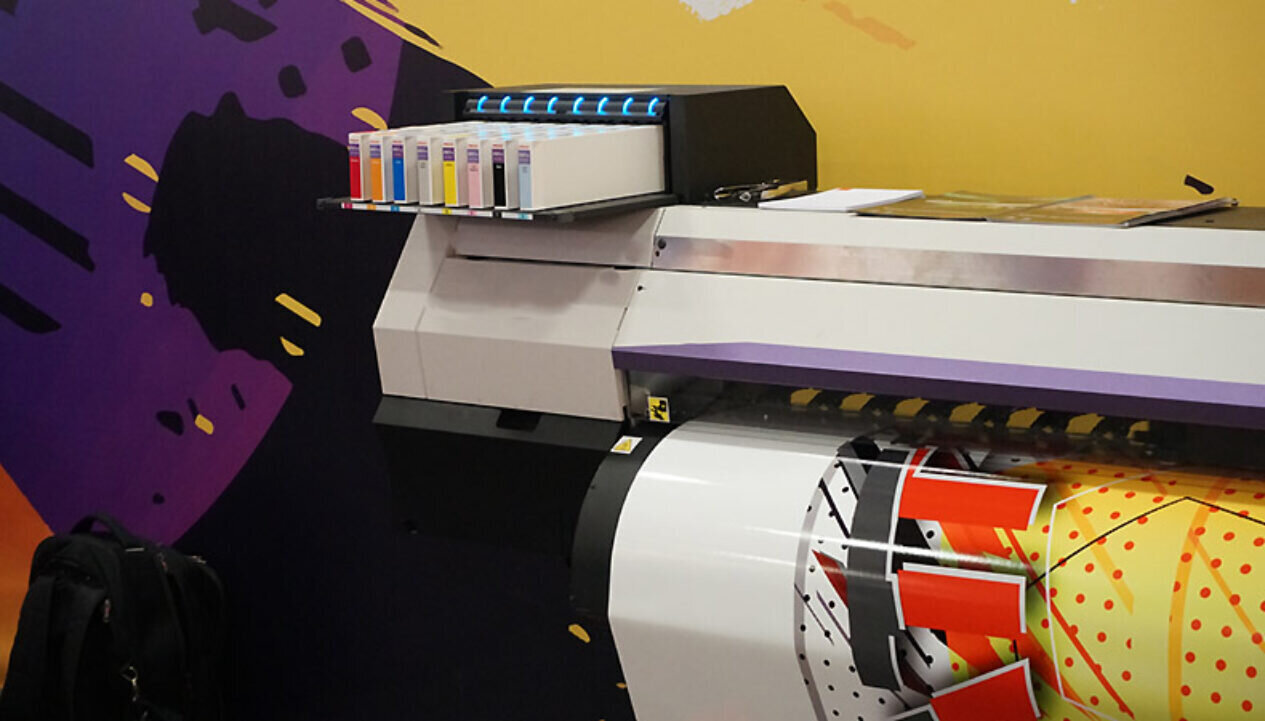

Let Eco Solvent prints rest for a minimum of 24 hours to prevent wrapping problems.

Image Credit: S. Angerer

5. Creases or Tears During the Wrapping Process

A common issue in vehicle wrapping installation is the material being creased or torn. This can be difficult to repair and may mean replacing the whole wrap altogether. Using a heat gun is key in preventing this as it helps to stretch and position the material, avoiding any wrinkles, creases, or tears.

Temperature is another key factor in vehicle wrapping, particularly when wrapping on beading and riveting. Depending on the brand, anything between 50 and 60 degrees usually works. For 3D surface wrapping, high quality cast film is a must, while cheaper vinyl is only suitable for flat or slightly curved surfaces.

Many vinyl brands offer an “Easy Apply” glue option with the backside adhesive applied in tiny dots or leaving channels, so any bubbles are easily removed. These are highly recommended for difficult wraps or training.

Make sure to prepare the wrap design for the right type und make, there are serious year-to-year differences between even well-known models.

Image Credit: S. Angerer

Understanding these vehicle wrapping problems will ensure a successful wrap every time. Resulting in vehicle wraps that last for years and happy customers.

Main image caption: Some problems in car wrapping are quite common, here is how to fix them or even prevent them from ever happening. Image Credit: S. Angerer