Debbie McKeegan speaks to Viktor Lazzeri, COO of Barbieri Electronic who shares his insights on the significance of accurate colour management regarding all methods of design and production.

The integration of cutting-edge technologies continues to disrupt, accelerate and rewire the printing industry. As technology evolves the print workflow requires unprecedented levels of precision alongside efficiency, with an increasing requirement for high-speed production – and accuracy – without which we cannot manufacture sustainably. In a recent conversation with Viktor Lazzeri, COO of Barbieri electronic, shared his insights on the importance of accurate colour measurement for all methods of design and production.

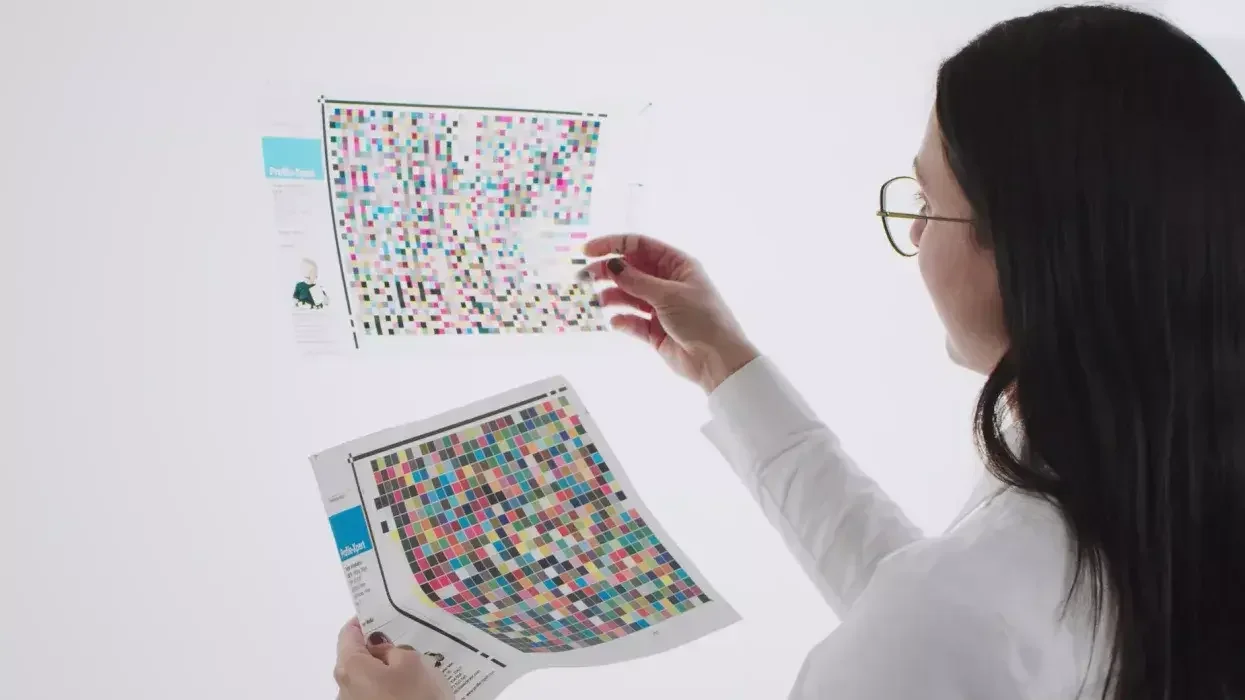

The integration of spectrophotometers, as highlighted by Viktor Lazzeri, has been instrumental in ensuring colour precision. By leveraging spectrophotometry, printers can capture and analyze spectral data, enabling precise colour matching and quality control.

The advent of cloud-based printing solutions and web-to-print platforms continues to streamline the production workflow, providing a seamless and efficient experience for both print service providers and customers. Cloud-based solutions offer enhanced collaboration, real-time job tracking, and remote print management capabilities, empowering businesses to optimise their operations and deliver exceptional printed products – However, without accurate process control, and manufacturing standards – no workflow can guarantee accurate digitally printed output.

One of the key insights from Lazzeri revolves around the importance of spectrophotometers in ensuring colour accuracy in digital printing. Traditional visual checks have become archaic in an industry that demands precision and replicability. By utilising technologies such as spectrophotometers, we can shine a light, quite literally, on printed materials and collect spectral data to achieve exact colour measurement. This technology shifts the focus from subjective visual interpretation to objective, data-driven decision-making, vital for a mature industry.

At the heart of effective printing operations lies process control and workflow optimisation. Lazzeri advocates for proactive process management to minimise waste, reduce reprints, and save operational costs. He shares a compelling example of a print shop that saved a considerable sum by using daily verification with a spectrophotometer to identify and rectify errors early in the production process. This approach to quality assurance spotlights the critical importance of operational standards within the manufacturing workflow.

Lazzeri also underscores the critical role of technology integration and automation in the industry. Routine tasks are prone to human error – a risk that can be mitigated through automation using technologies like spectrophotometers. Beyond just efficiency, he envisions secure production facilities with tight controls to ensure minimal waste of resources, time, and materials. The aim is not just to do things “right” but to do the “right things”.

The printing industry, while evolving, must also keep in mind the importance of knowledge sharing and education. Lazzeri believes in the power of open communication and collaboration to bridge the gap between traditional analog and digital methods. “Continuous learning about colour measurement and management for digital technologies is not merely an option – it is a necessity for growth and sustainability.”

Lastly, Lazzeri turns our attention to the promising future of colour management. In his view, “the industry has barely tapped into the potential of this realm”. He suggests that “as we continue to explore the capacity of tools like spectrophotometers to achieve the right colours, we will uncover even more opportunities for innovation and improvement within our industry”.

It is clear that the continuous integration of technology, an emphasis on process control, and a commitment to lifelong learning are key aspects of success. Viktor Lazzeri’s vision for a technologically advanced, efficient, and collaborative industry is a call to action for us all to rethink and reshape our approach to printing and a make a commitment to continuous improvement.

To discover the latest content that covers a wide range of sectors including colour management, automation and process control sign up for FESPA’s free monthly newsletter FESPA World available in English, Spanish and German.