Nessan Cleary offers advice on how to choose between screen printing and digital printing for t-shirts, garment and garment decoration.

There’s been a huge growth in the popularity of garment printing in recent years, with a choice now between several different technologies, each of which have their own pros and cons that we will go through in the course of this article.

However, I’m going to start by drawing a distinction between fabric printing and garment decoration. The highest volume textile printing involves using roll-fed devices printing direct to fabric. That could mean printing a given design across a whole width of the fabric, or it could mean just printing the pattern for the planned garments. But either way the garments will have to be cut out of that roll of fabric and stitched together to create the finished item.

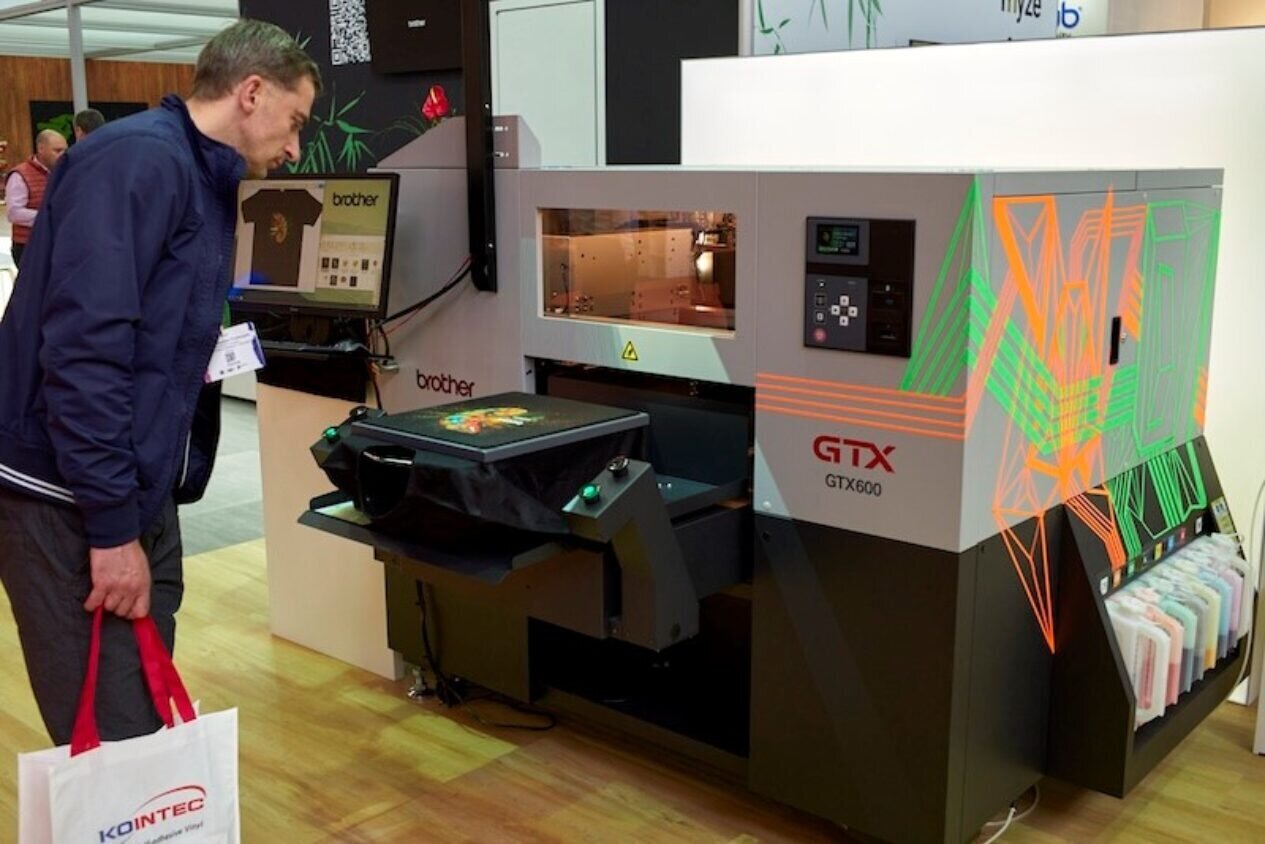

Brother has added orange and green inks to the GTX600 Extra Colours DtG printer.

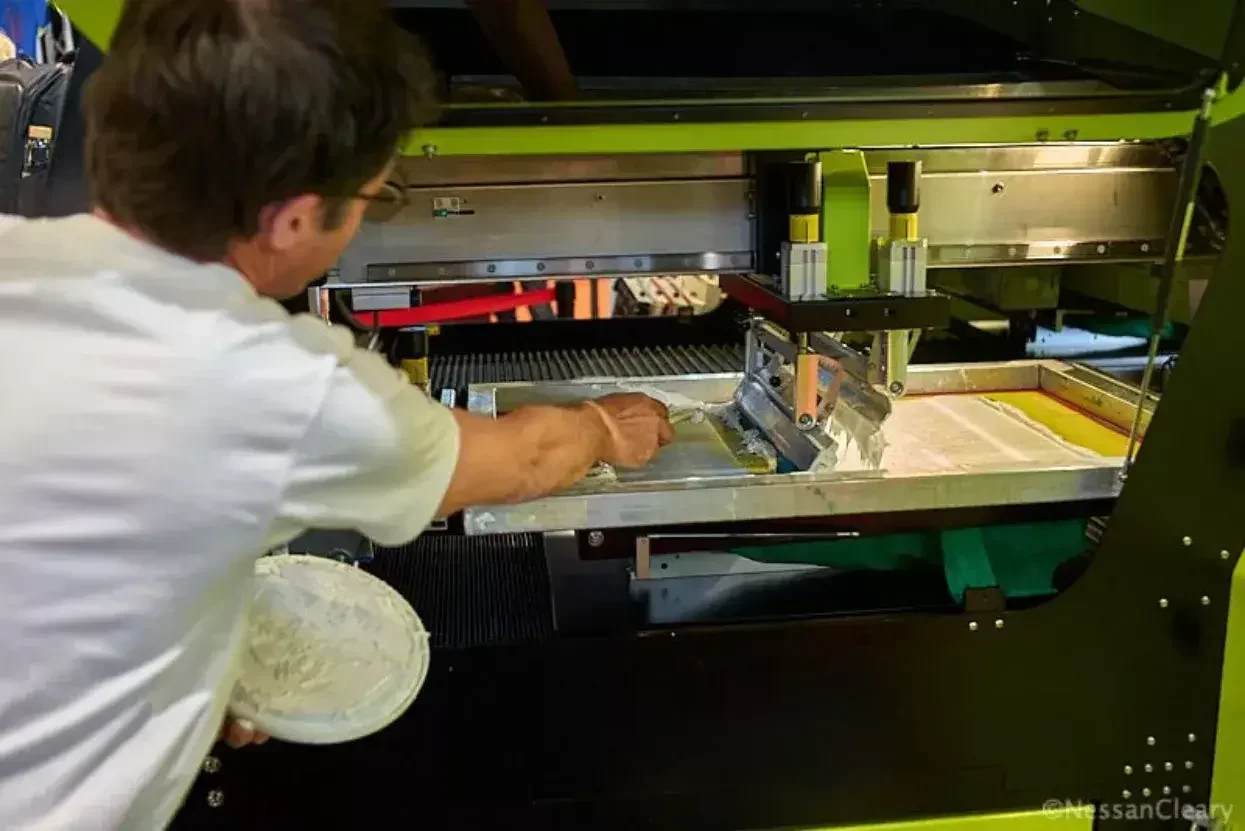

Image credit: Nessan Cleary

For this story, we’re only going to look at garment decoration, that is, taking a blank garment that’s already been produced, such as a t-shirt or hoodie, and then printing to that garment to add value. It’s an important distinction because it means that there’s no need for any further cutting or sewing, but also that the printing process has to take into account any existing seams in the garment.

There are three principle technologies to choose from: screen printing, Direct-to-Garment or DtG, and Direct-to-Film or DtF. We’ll look at the differences between the two digital approaches, DtF and DtG, next month and just consider the pros and cons between screen printing and digital for this story.

Perhaps the main consideration to take into account is the volume of work. In terms of productivity, there may not be much to choose between a manual screen printer and a desktop digital device. There are a number of industrial scale DtG printers, from vendors such as Kornit and Aeoon that can offer a very high throughput. But for sheer volume it’s hard to beat an automated screen printing machine, which can produce an enormous number of garments per hour.

Aeoon's Kyo Hybrid combines screen printing with digital technology.

Image credit: Nessan Cleary

As a general rule, digital printing can produce very finely detailed work as well as gradients, something that is near impossible for screen printing.

Screen printing is still a relatively analogue process, despite some digital prepress and a high level of automation of the machines themselves. This means that there is time and cost involved in producing the screens and setting the machines up for each run so that it’s better suited to medium to long runs. One of the features of screen printing is that each colour requires a separate screen. So the more colours a particular design needs, the greater the set-up costs of producing those screens. And of course each additional colour also slows down the overall productivity.

With most digital printers you’re limited to the inks that the manufacturer has designed for them. In most cases that will mean a CMYK inkset so you’ll be limited to the colour gamut this can produce. The entry level machines may not include white, though you absolutely will need white ink if you want to be able to print to darker materials, in order to help the colours stand out from the background. Some digital machines do include more colours, though these are generally more expensive.

With screen printing on the other hand, there’s a wide range of inks from different manufacturers. The choice largely comes down to suitability for the job in hand, and personal preference and experience. This in turn means that screen printing machines can generally handle a wide variety of different fabrics, and can produce extremely rich, saturated colours. The print results usually have a long life and will withstand many washes.

That said, the hand feel is generally better and more natural with digital printing rather than screen printing. This is because the ink is laid down in a thinner layer and usually penetrates into the fibres of the fabric. Most screen printing inks include plastisol, which gives the graphic a rubbery feel though this can be reduced by adding a softener to the ink.

There’s very little makeready associated with digital devices so that each item printed costs the same, meaning that very short runs, or even individual items are more cost-effective than longer runs. This means that for e-commerce based businesses catering to personalised items or very short runs then digital is a very attractive option, with a clear pricing structure around the number of prints needed.

But it’s still the case that the personalised fast-fashion market is relatively small compared with the larger garment retail market, which usually operates on much longer runs. This plays better to the strengths of screen printing.

Screen printing does require quite a lot of skill, even when working with the more automated machines, so there is a higher staff training cost. Digital printers are much easier to manage. They’re not quite push-button as operators still need to exercise some judgement in applying primer, and of course have to load the platens correctly. However, some people like the process of screen printing and feel that it gives them the leeway to produce better results. Many screen printers also say that they are more comfortable moving to DtF rather than DtG printing.

Of course, you can always go a combination of both worlds as there are some hybrid machines that include both digital and screen printing. Aeoon, for example, makes the Kyo Hybrid, which is essentially an industrial DtG printer with two platens for high productivity. It also has a single screen printing station at the back of the machine that allows users to add special effects or colours.

In conclusion, the different print technologies shouldn’t really be seen as competing alternatives, but rather as tools for specific jobs. Many suppliers working in the garment decoration market may well find that they need to have a mix of several or all of these types of devices to satisfy different parts of their customer base.

Discover the latest innovations in both screen and digital printing at FESPA Global Print Expo 2024, Europe’s leading print and signage exhibition. Taking place from 19th – 22nd March 2024 at RAI Amsterdam, Netherlands. Register here to visit and use code FESJ404.